VACUWORX,

USA

O

il and gas pipe may have to be transported hundreds

or thousands of miles from point-of-origin to final

destination, resulting in numerous touch points for

multiple stakeholders tasked with the safe handling

of materials at various intervals.

No two pipe-handling tasks are exactly alike, making the

best course of action to carefully consider the circumstances

of each lift. This includes an assessment of all known risks to

determine appropriate handling procedures as materials are

being loaded on and off trucks, staged for inspections or repairs,

racked in storage yards, and delivered to the right-of-way.

Safety is a major focal point for operators in the pipe

manufacturing, pipeline construction, and logistics services

sectors. According to Randy Hayes, Vice President of Business

Development and Strategic Accounts with Vacuworx, they tend

to lean toward versatile, turnkey solutions intended to mitigate

jobsite hazards and help boost productivity.

Demand for alternatives to traditional cable and slinging

methods of handling pipe has led to widespread adoption of

vacuum lifting technology over

the past two decades. Vacuworx,

a global provider of heavy-duty

lifting solutions for oil and gas and

construction-oriented industries,

introduced the first of its RC Series

Vacuum Lifting Systems in 2000. The

product line was specifically designed to

offer a safer and more efficient way to load,

unload, stage, and place pipe.

The RC Series is available in five different

models geared toward energy and infrastructure

projects, as well as material-handling operations

at manufacturing plants, port facilities, and laydown

yards. Powered by self-contained diesel engines,

standard RC Series lifters are compatible with large-

capacity carrier equipment and boast lifting capacities

that range from 22 000 lb to 55 000 lb (10 t to 25 t).

Every RC lifter features wireless remote operation and

360˚ rotation that provides for the precise placement of

the pipe being lifted, and eliminates the need for cribbing

or spacers. Vacuworx’s specially formulated vacuum pad seal

technology is designed to prevent damage to delicate materials

and bonded coatings, limiting the need for time-consuming

repairs. The units require minimal set-up and are capable

of handling pipe from 4 in. (101 mm) to an unlimited outer

diameter.

The Tulsa, Oklahoma-based manufacturer has invested

heavily in continuous improvement of the RC line,

including the launch of environmentally friendly ‘H’

models that eliminate noise, emissions, and fuels costs

by drawing power directly from the host machine.

Vacuworx lifting systems are available for rent

and purchase worldwide through a network

of authorised distributors and directly

through the manufacturer. The systems can

additionally be customised for in-plant lifting

solutions to handle all types of pipe and

various raw materials in manufacturing

environments, or for specific materials

and applications. Parts, service, and

shipping options are available all year

round.

“The focus of our RC product

line always has been, and

continues to be, on keeping

people safe,” Hayes said.

“Regardless of project

scope, preparation is the

key to ensure people,

assets, and budgets are

protected the entire

way.”

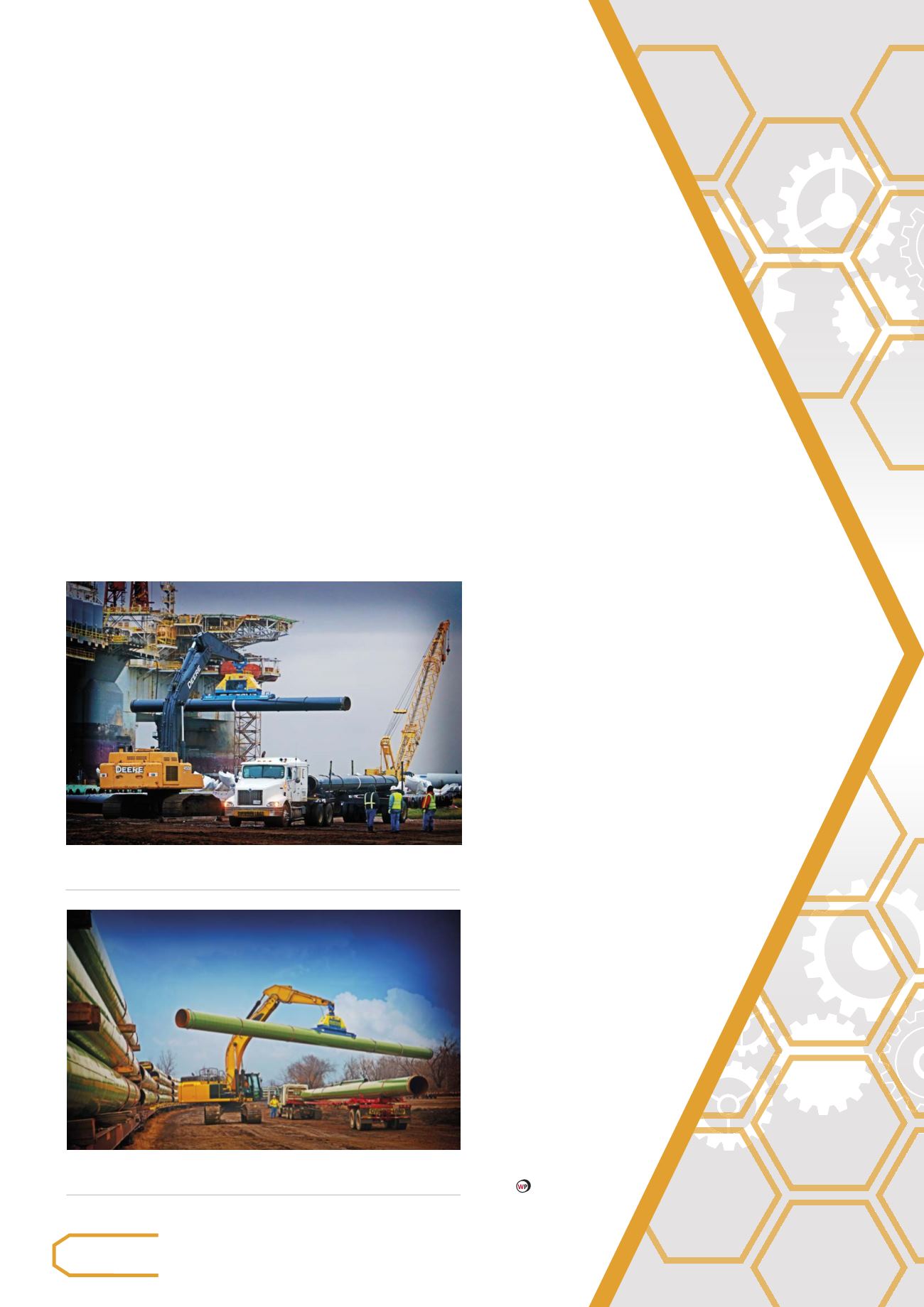

Dun Transportation & Stringing shown unloading pipe from rail to

truck using Vacuworx RC 16.

American Pipe Handlers using an RC 20 to transfer pipe from

barge to truck.

Heavy equipment review

56