Solving tough integrity challenges

The issues are hardly insurmountable. However, the ILI industry

is successfully applying learning models to solve challenging

problems every day.

For example, when there was no general sizing model to

apply to SSWC, and dents with gouges from coincidental

corrosion – specific pipeline threats with small populations

and unique characteristics – TDW developed two separate

learning models to classify them.

5,6

The models were based on

strategically engineered features only available in the MDS data

sets; when applied to the outliers in pipeline A, they predicted

a 99% probability of SSWC and correctly classified both

dents as having associated gouging. By focusing the model’s

objective on specific anomalies, it was possible to create

adequate input features, which shrunk the prediction space,

improved predictions, and ultimately gave operators a more

comprehensive way to prioritise mitigation plans and manage

pipeline integrity.

ML is also being applied to help pipeline operators comply

with current regulations that require the material properties of

joints of pipes to be traceable, verifiable and complete.

Pipelines with incomplete documentation are a perfect

problem for unsupervised ML – that is, where the model

receives input for each example and attempts to discover

the structured patterns within the data set on its own. MDS

ILI using high field MFL, axial low field magnetic flux leakage

(LFM), and high-resolution profilometry deformation (DEF),

can match joints of pipe by using the signals from patterns

in permeability and bore variations created during the

manufacturing process.

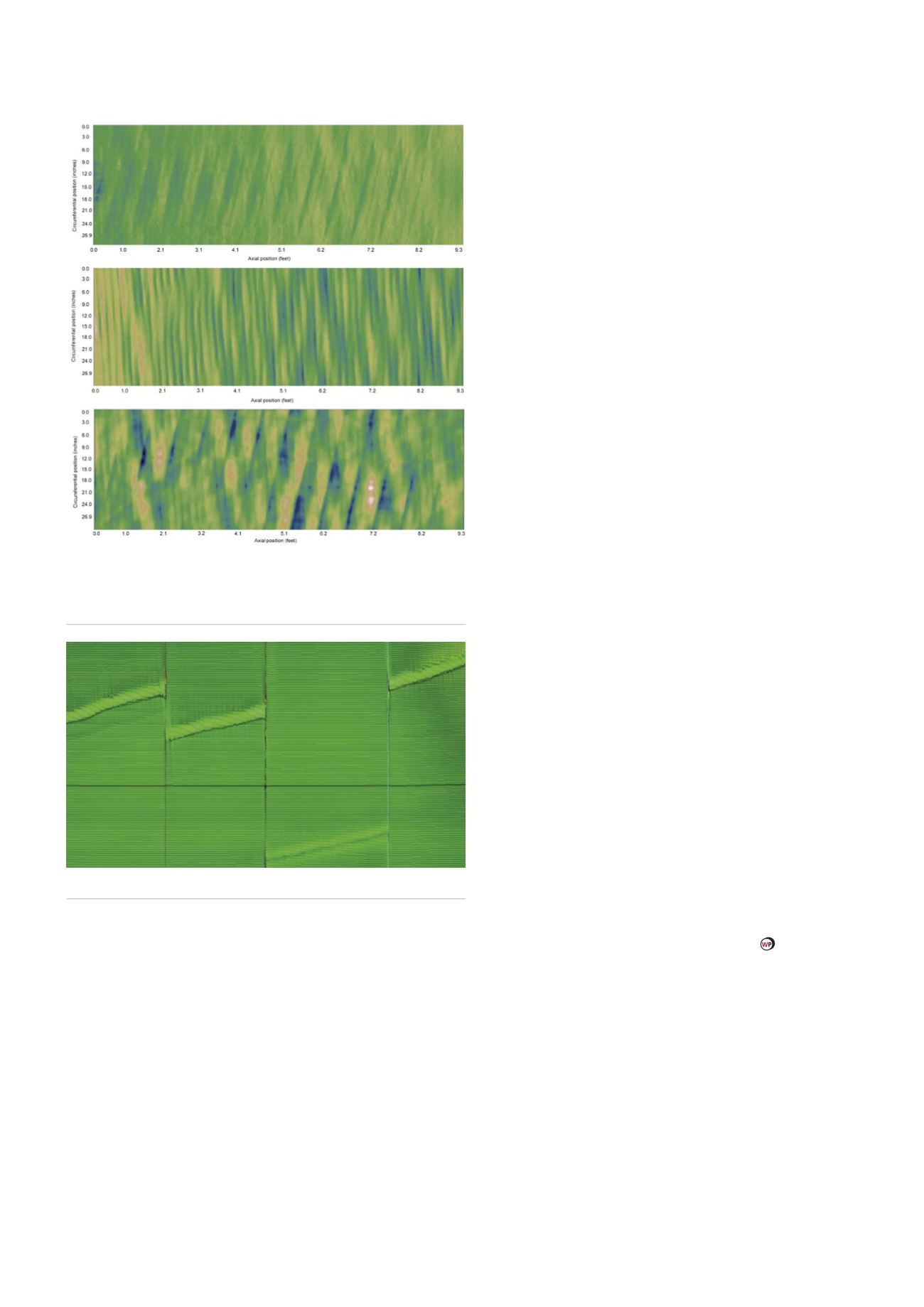

As Figure 4 illustrates, each data set has distinctive

markings and patterns consistent with other joints made

from the same material and manufacturing process. SMFL,

which is sensitive to axial features such as long seam welds,

can also be used to match joints of pipe. Seams made from

the same manufacturing process will generate similar signals,

while features for the seams will be different than for the pipe

body (Figure 5). The variability in the seam welding process

compared to steel rolling and forming often means the criteria

for similarity must be adjusted. Knowledge of the real-world

factors – in this case, knowledge about seam welded pipe

manufacturing – is essential to developing a good ML model.

Protecting pipelines

Protecting consumers against fraud and pipelines from

integrity issues may seem lightyears apart, at least in terms of

how severe a lapse might be. After all, the problems associated

with a stolen credit card tend to be more annoying than

anything, which is a far cry from the risk of a pipeline leak or

other failure.

But just as the banking industry and many others are

benefitting from the strengths of ML applications, so is ILI. The

ability to focus models on specific threats, use subject matter

experts to tailor input features and leverage multiple data sets,

will help keep pipelines the safest transportation method. The

continued advancement and practical utility of future ILI ML

will depend largely on the availability of more high-quality

data sets, coupled with close collaboration between data

scientists and highly skilled pipeline engineers.

References

1.

ATHERTON, D.L. and DALY, M.G., ‘Finite element calculation of magnetic flux

leakage detector signals,’ NDT International, Vol. 20, No. 4, (1987), pp 235-238.

2. YANG, S., SUN, Y., UPDA, L., UPDA, S. and LORD, W., ‘3D Simulation of Velocity

Induced Fields for Nondestructive Evaluation Application,’ IEEE Transactions on

Magnetics, Vol. 35, No. 3, (1999), pp 1754-1756.

3.

NESTLEROTH, J.B., RUST, S.W., BURGOON, D.A. and HAINES, H., ‘Determining

Corrosion Defect Geometry from Magnetic Flux Leakage Pig Data,’ Corrosion96

(March 1996), NACE-96044.

4. BUBENIK, T. A., NESTLEROTH, J.B., DAVIS, R. J., CROUCH, A., UPDA, S. AND

AFZAL, A. K., ‘In-line Inspection Technologies for Mechanical Damage and SCC in

Pipelines: Final Report,’ US DOT, OPS, (2000).

5. NESTLEROTH, B. J., SIMEK, J. AND LUDLOW, J., 2016, ‘New Classification Approach

for Dents with Metal Loss and Corrosion Along the Seam Weld,’ Proceedings of

the 2016 11

th

International Pipeline Conference (2016), p. 10.

6. ANDREW, J. and SIMEK, J., United States of America Patent No. US 2019/0162700

A1 (2019).

Figure 5.

SMFL data taken for joints with different seam welds.

Figure 4.

Top: the measured magnetism of a joint of pipe

using high field axial magnetisation. Centre: using low field

magnetisation. Bottom: high resolution measurements of the

radial distance to the inner surface of the pipes.

62

World Pipelines

/

MARCH 2020