Heavy equipment review

SCAIP S.P.A.,

ITALY

S

ince 1980, SCAIP has

been developing

and manufacturing

equipment for the

pipeline sector. SCAIP designs and

produces its machines in Parma, Italy,

with a location in Denver, Colorado

(US) to support sales in the Americas,

along with its new distributor Cross

Country Infrastructure.

SCAIP handles direct sales for Europe and

other countries directly from its Parma offices,

whose facilities host a production of more than

250 units of equipment per year. Technological

development and advancement are SCAIP’s top

priorities; not only are these developments designed

to improve the safety of the company’s machines for

the operator, but also to improve the ergonomics and

environmental impact they have on the planet.

SCAIP develops and manufactures specialised padding

machines for the oil and gas industry; these feature

adjustable vibrating screens (or rollers), adjustable and folding

conveyors, ROPS protection, and newly designed operator

cabins, which are designed to improve operator comfort and

safety in working conditions.

After analysing the past and current padding machine

cabin design, SCAIP considered the following factors during

the design phase of the new cabin: increase the visibility for

the operator; ergonomics, comfort, and a safe environment;

minimise disassembly time and number of pieces for

transportation; and remove high ladder to access the

cabin.

In order to achieve these improvements, SCAIP

implemented a solution that allows the cabin

to rotate and move vertically. The new cabin

design is in a patent pending stage. The cabin

is able to lift and pivot on the vertical and

horizontal axes, and can turn up to 90˚.

With this new cabin design, the

operator can easily access the cabin

that is now closer to the ground in

the parking stage, with just a few

steps to exit and enter the cabin.

During transport, the cabin can

be moved down inside the

escalator.

In this way, it is not

necessary to disassemble

the cabin prior to

transportation; the

ROPS is integrated

with the cabin.

These redesigned

cabins oscillate, and are temperature controlled. The padder

is also remote controlled.

Bending machines were among the first pipeline

equipment to be produced by SCAIP. These machines can also

be equipped with cabin and air conditioning units.

Most notably, SCAIP’s SPB 48-60 series of pipe bending

machines have recently improved transportation capabilities,

in order to comply with the EU transport regulations. The

machine has a lightweight but robust frame, and parts that

are easily disassembled and reassembled. The maximum width

can be reduced to 3 m. This provides ease of transportation

for the large machine.

Furthermore, together with SICIM S.p.A., a new system

to hook up the pipe has been developed. This means the

operator can avoid climbing the machine and the pipe to

ensure the hook is on the pipe end. The hook position can be

controlled by the platform together with the other functions,

reducing the safety risk.

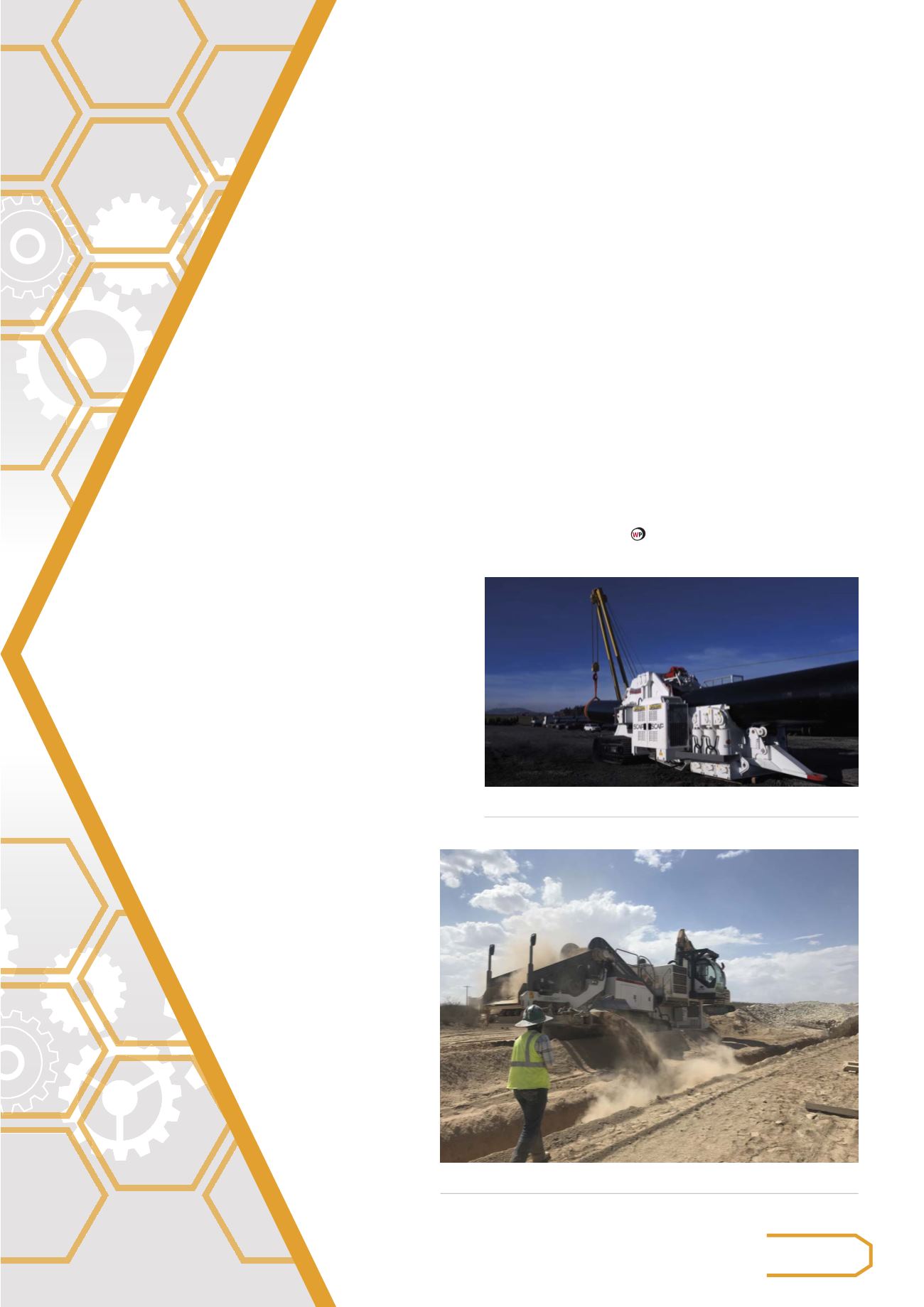

Padding machine SPD 350 in New Mexico, US.

Bending machine SPB 48-60 in the Czech Republic.

51