Predicting model performance

Assigning performance to these models can be difficult at

times. They require lots of training examples, which can leave

few remaining examples for testing. Incidentally, this is one of

the pitfalls of using a small number of features from a single

inspection to predict integrity threats.

To illustrate this issue, TDW trained an ML model to predict

metal loss depth using a few simple features – signal amplitude,

length, width and wall thickness (t) – and applying a more

advanced learning technique called gradient boosting regression.

The training data set included more than 100 samples of high-

quality field investigations from pipeline A.

Figure 1 shows the distribution of metal loss depths and a

unity plot of the residual errors against depths measured in the

field for pipeline A. The prediction performance is quite good,

which is expected because the model is making predictions on

the data it was trained with. However, there are some interesting

outliers, circled in red and orange in Figure 2. Taking a closer look

at the associated ILI data sets can provide insight into how they

came about.

In the case of the red outlier in Figure 2, axial magnetic flux

leakage (MFL) (top right) indicated two independent metal loss

signatures. However, spiral magnetic flux leakage (SMFL) (bottom

right) revealed they are actually one long, connected feature.

The high amplitude response on a single sensor in the SMFL data

set and association with the long seam were consistent with

selective seam weld corrosion (SSWC), which poses a serious

integrity concern compared to general metal loss crossing the

long seam. This feature was verified in the field as SSWC. Similarly,

field results for the orange outliers found gouging associated

with dents. Since the vast majority of the training data was not

SSWC or gouges associated with dents, and the model input

features were inadequate to accurately characterise them, it is not

surprising that the model did not perform well here.

Despite these few outliers, the performance of the model

is still very promising. However, knowing how the model will

perform on the next inspection requires testing it on a blind data

set, in this case, pipeline B, which was similar in sample size to

pipeline A.

Figure 3 shows the distribution of metal loss depths for

pipelines A and B, and a unity plot of the prediction performance

against field depths for pipeline B. The performance is nowhere

near what TDW had observed on pipeline A. Instead, metal

loss depths are generally overestimated. Comparing the metal

loss depth distribution for both pipelines shows that pipeline A

contains generally deeper metal loss samples, above 0.40 t, while

pipeline B contains shallower samples, below 0.40 t. Even though

there are some overlaps in the metal loss depths, it is likely that

the model learned the input features for deeper depth metal loss

and poorly extrapolated them to shallower depths.

Of course, no two pipelines are alike. The differences

between pipelines A and B also contributed to the poor

prediction performance on pipeline B. But the fact is, collecting

enough data to represent all the geometries, at all the depths,

across all the material types and all the other permutations,

is an arduous task. Dimensionality reduction techniques, laser

profilometry, and finite element modelling (FEM) all help to

reduce the complexity, but large-scale challenges still remain.

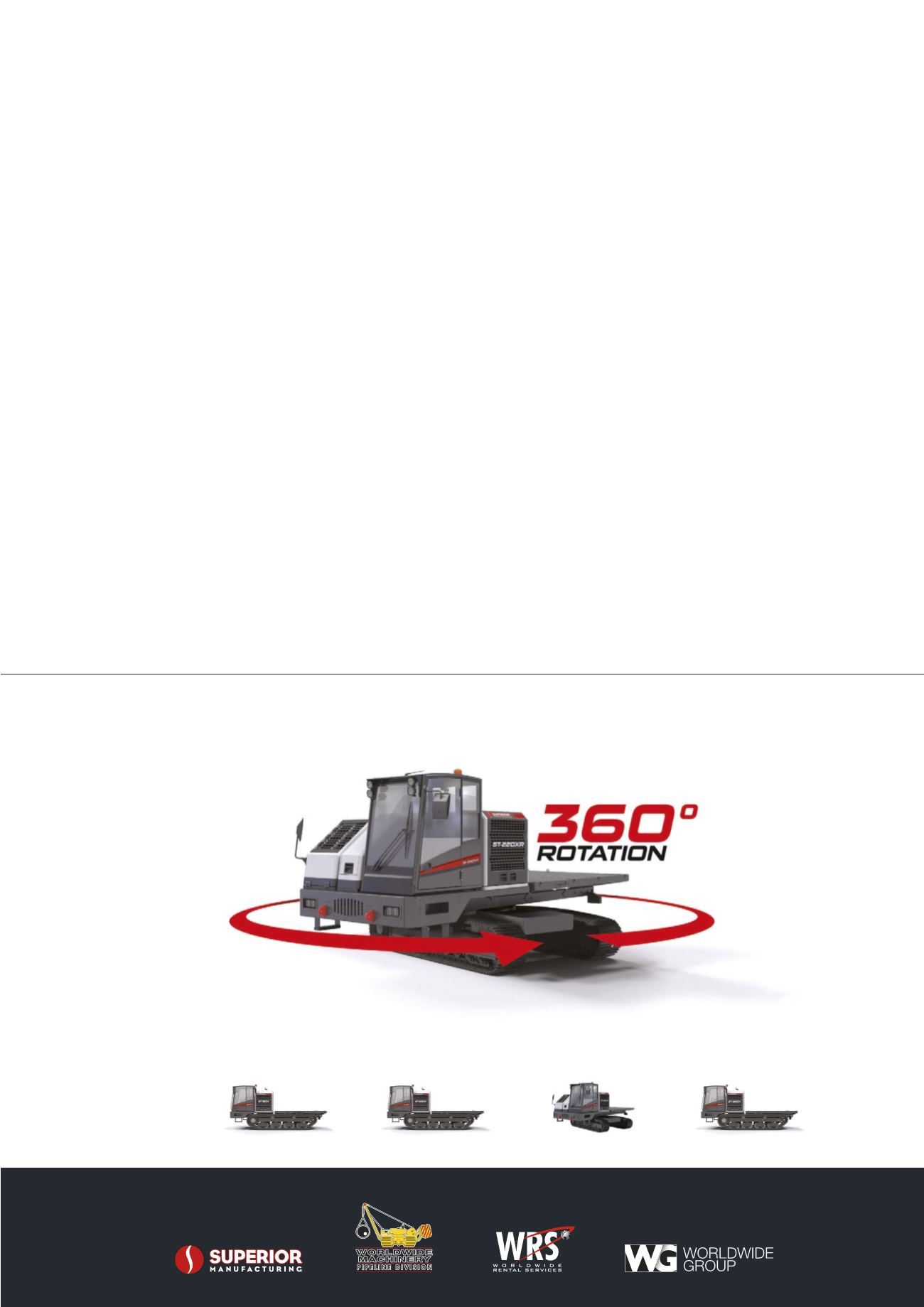

Lookwho’s Turning Heads!

Email us at

sales@superiormftg.com, visit

superiormftg.com/carrier ,or call your Worldwide rep

Superior Manufacturing™ is a trademark of Worldwide Machinery.

Our Crawler

Carrier Line-Up:

ST-150X

ST-220X

ST-220XR

ST-300X

Introducing the New Superior ST-220XR Crawler Carrier

With a 22,000lb payload, swappable cabins and undercarriages, and easy to switch purpose driven beds,

the 220XR turns out quality results for any project.