has also been quick to participate in the modern ML era, using its

tools to increase efficiency, control costs, and support integrity

management. Applying ML techniques to inline inspections (ILI)

performed by intelligent pigs is improving the actionable data

that pipeline operators need to keep their systems running safely.

Expanding ML use

Given the current fervour for ML, it might be surprising to

discover that ILI providers have been applying ML since the

1980s, although at first it was not explicitly referred to as such.

Early models were constructed using a combination of finite

element modelling, statistical modelling, and predictive functions,

to address such challenges as predicting metal loss geometric

dimensions.

1,2,3

The application of formal ML techniques began in the

early 2000s with neural networks – that is, connected layers of

non-linear functions – being used to classify pipeline features

and identify mechanical damage. Since then, the application

of ML has improved metal loss sizing, fitting classification, and

the identification of interactive threats.

4

The development

of advanced ILI techniques such as electromagnetic acoustic

transducer (EMAT) and ultrasonic (UT) technology have generated

even more interest in ML as a way to analyse complex data sets.

Given its success, it is tempting to think of ML as a silver

bullet that can solve any problem. But the fact is, even when the

goal seems outwardly simple – to alert people about possible

credit card fraud – there is no single model that can be employed

with certainty, and often the goal has more complexities than

initially considered. The best solutions begin with well-thought

out, well-defined objectives; they often apply a combination

of multiple models that either feed into one another or are

ensembled together to produce a final prediction; and they rely

on good data, which is not always easy to assemble.

Fine-tuning data

Data curation – the process that includes collecting, analysing

and labelling the data used to train the mathematical model – is

a critical and time-consuming process. The quantity, quality,

and representation of the data directly influence the

performance of predictions made by the model. For example,

if you want to predict housing prices in Tulsa, Oklahoma, but

use a model trained on data from Los Angeles, California, then

the resultant predictions will be grossly incorrect. Even slight

nuances can manifest as misleading results. However, it is

possible to formulate the model to reduce the risk of error.

In many ways, implementing an ML model to accurately

identify possible integrity threats mimics the experience-based

approach of ILI data analysts who detect, identify, and report

signals recorded by ILI tools. Experience can be subdivided

into two categories, examples and outcomes, each of which

allows the data analyst to identify patterns and make future

predictions.

The same goes for supervised learning models. They make

predictions from examples and outcomes, and improve the

more ‘experience’ they have.

Supervised models use a one-to-one mapped set of

inputs (examples) and outputs (outcomes) to develop a

mathematical function that can be applied to new examples.

The input parameters are a vector of engineered features (that

is, important characteristics) that map to a desired outcome.

A model’s training data will include numerous examples: each

example will have a list of features, and each example will have

a desired outcome. The model uses this data arrangement to

learn rules that can be applied to future examples.

The beauty of these models is that they can be trained using

multiple features. At T.D. Williamson (TDW), for example, the

multiple data set (MDS) platform allows subject matter experts

to develop relevant, focused, and valuable input features that

can be used to train models, make integrity predictions, and

provide comprehensive threat assessment.

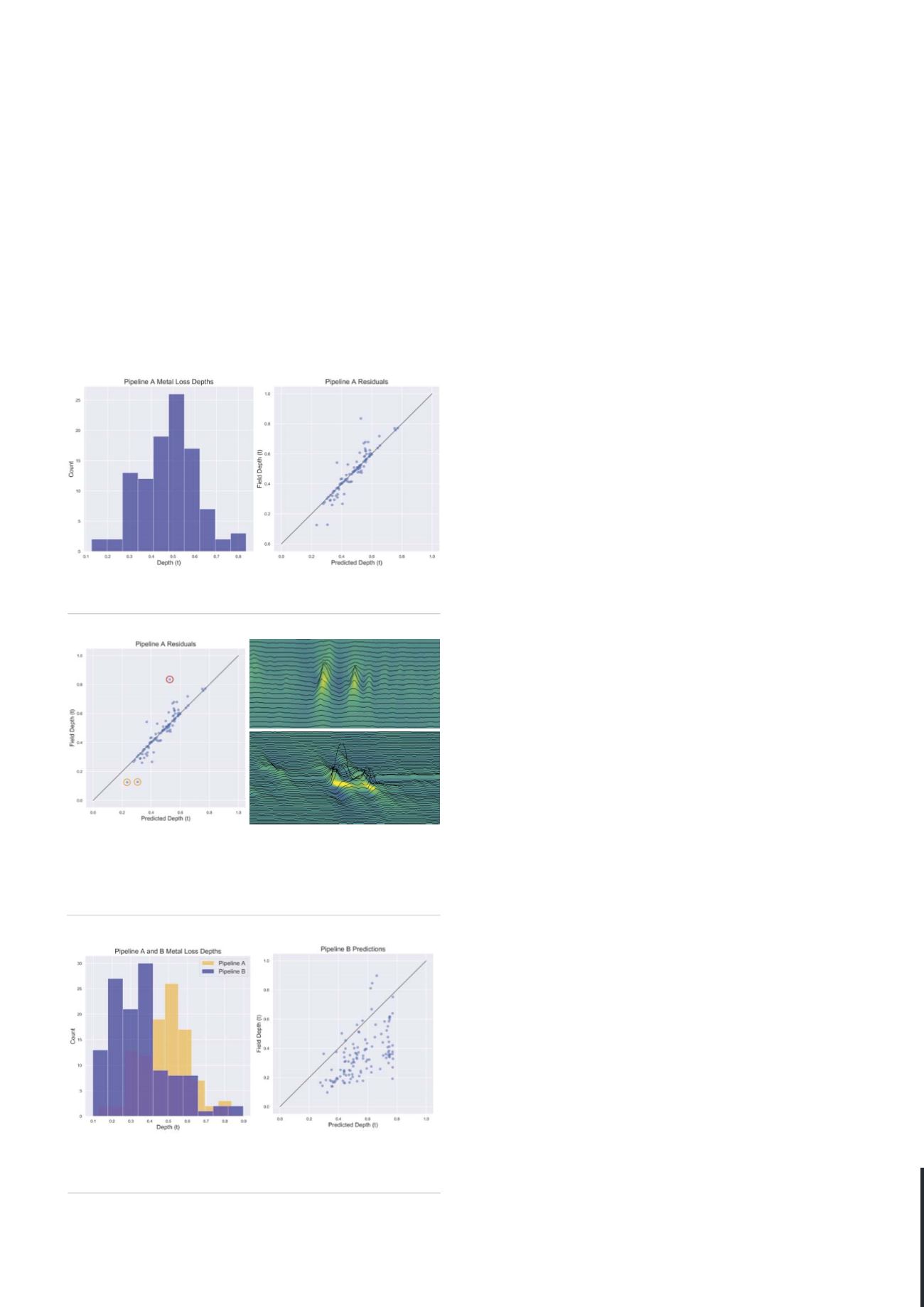

Figure 1.

Model prediction performance is closely aligned with

field results.

Figure 2.

Looking closely at the data sets shows how the outliers

came about. Top right: magnetic flux leakage (MFL) indicated two

independent metal loss signatures. Bottom right: spiral magnetic

flux leakage (SMFL) indicated on long, connected feature

consistent with selective seam weld corrosion (SSWC).

Figure 3.

When the model was tested on a blind data set,

it overestimated metal loss depths, probably due to poor

extrapolation from the input features it had learned.

60

World Pipelines

/

MARCH 2020