PROLINE PIPE EQUIPMENT, INC.,

CANADA

T

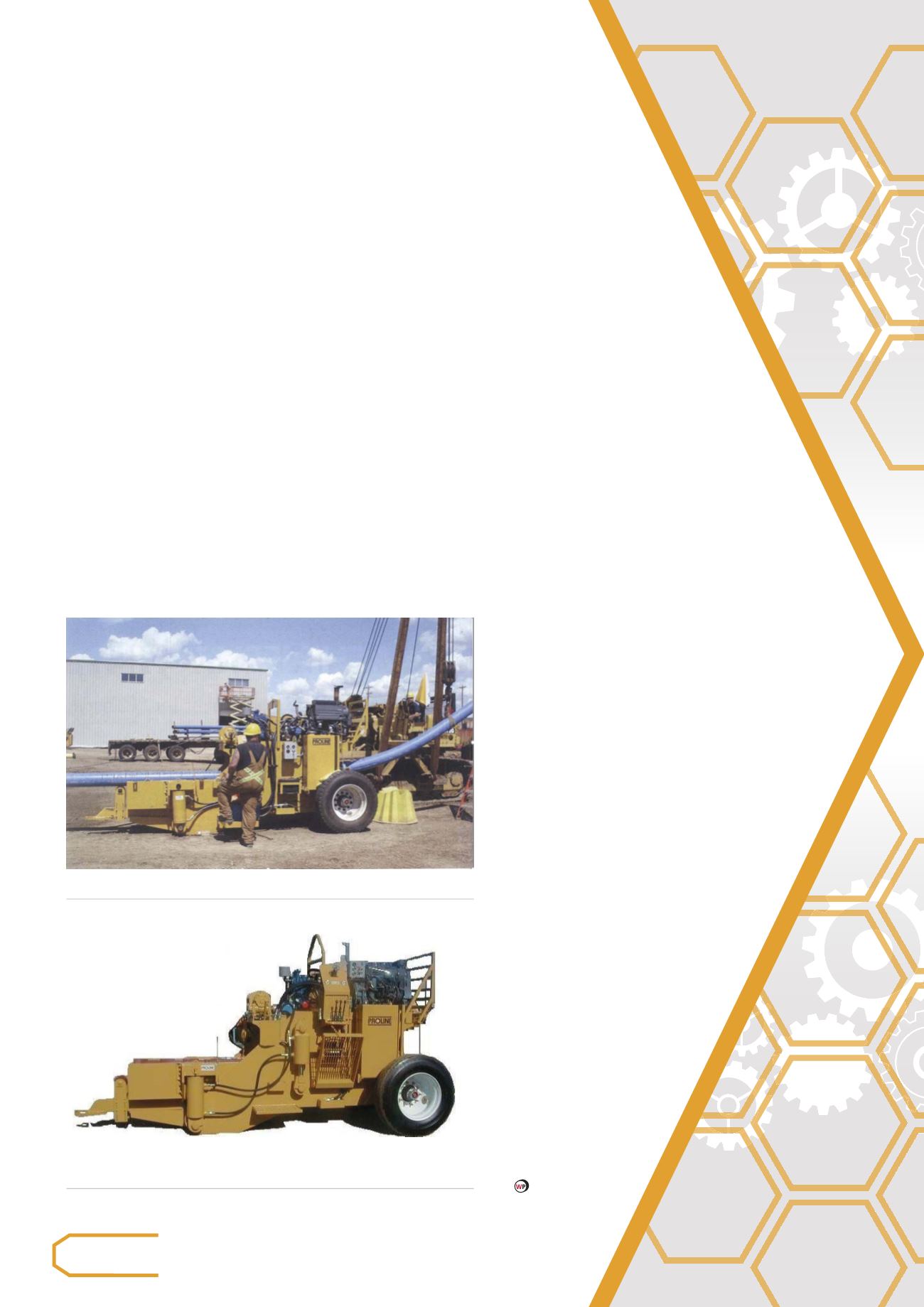

he Proline BM04-20HD heavy-duty bending machine

is designed to be tough. One of the advantages of

this bender is an efficient hydraulic cooling system,

which keeps the hydraulic fluid from overheating

under extreme jobsite conditions. Other advantages include

safety shutdown, larger than average side plates, and specially

designed filters. The rims and tyres are oversized (compared to

other machines in the market) so that it is easier to move the

machine through sand, snow, and swamp. Proline produces six

sizes of bending machines.

This particular heavy-duty machine will bend pipe of

various wall thicknesses from 4 in. - 20 in., and incorporates

an extended bed with a Quincy compressor to power the

mandrels. The Proline open front design allows the operator to

see the pipe coming into the bender, and gives them a better

view of the bending procedure, unlike the box-shaped bending

machines that are currently being used.

Contractors who work on high production pipelines

currently use this machine in Canada. These contractors are

well-known for their speed and expertise in laying cross-

country pipelines, and they

require reliable equipment to

keep production at maximum

levels. In Canada, high production

can be achieved at 40˚C, as well

at -40˚C. These ‘benders’ have been

proven to work at 50˚C, while working

on projects in the Algerian Sahara.

In 2003, Trans Canada Pipelines used

a Proline pipe bending machine to see if

experimental 36 in. X100 grade pipe could be

bent, and if it could be bent in cold weather.

Proline’s BM3042 bent the pipe in -45˚C

conditions along with a self-powered mandrel;

in fact, it bent the pipe all day. This is the heritage

from which the BM04-20HD comes.

Proline servicemen have travelled overseas to train

customers’ employees on the use of the equipment at

their location and for start-up procedures. The company

does this for mandrels, air clamps, and other Proline-

manufactured equipment.

While Proline is a manufacturer of pipe bending

machines, the company also carries lowering-in belts,

rockshield, horizontal ground rollers up to 1219 mm (48 in.),

and stackable plastic pipe stands for normal or high heat

conditions – this frees up the time it takes to build skids,

and does not require fumigation certificates. The company is

focused on helping customers reach their goals in a timely

and cost-effective manner. Customers in 64 countries have

benefitted from Proline offering training sessions for

their employees. At the company’s facility in Canada,

they are trained to use the equipment safely. Once

the course is completed successfully, an employee

will receive a certificate of achievement.

Proline bending machines were designed

with pipeline workers in mind. In fact,

several ideas were incorporated into the

bending machines from the same workers

who are experienced in cross-country

pipe bending. That is why Proline

incorporated the bending machine’s

shape over 25 years ago. Special

features of a Proline bending

machine include working in -45˚C

to 50˚C with only a change of

fluid. There are no optional

‘cold weather packages’ or

‘hot weather packages’. The

machines simply work

in these environments

because that is what

they were designed to

do.

The Proline BM04-20HD bending machine has an extended bed and

a built-in air compressor to accommodate bending mandrels.

The Proline BM04-20HD bending pipe.

Heavy equipment review

50