The identified geohazards will be studied in detail during

subsequent phases of the project; however, the unusual nature

of the fault crossing at the OFZ and crossing of the deep Indus

Fan channels prompted SAGE to undertake early geohazard

studies on these features, to confirm the viability of MEIDP

crossing them.

Owen Fracture Zone

The OFZ is a large fault system over 800 km long at the tectonic

plate boundary between India and the Arabian plates. At the

MEIDP route crossing point the OFZ takes the form of a strike-

slip right lateral fault. The fault forms a canyon 200 m deep and

1.3 km wide in a water depth of 3400 m.

The pipeline route resulting from the RMS has been used

to undertake a bottom roughness assessment of the pipeline

at the OFZ crossing. This analysis determined the stress state

and spanning condition of the pipeline. The assessment shows

that the defined route is suitable with no major requirement for

intervention.

The OFZ in the region of the MEIDP route has significant

seismic activity. SAGE seismic hazard studies indicated that

earthquakes of magnitude Mw

>

7.0 were possible and could

result in large seafloor movements. In order to understand the

possible implications of large strike-slip right lateral seabed

movements at the OFZ, SAGE has performed pipe stress

assessments on the 3D seabed with a forced 7 m movement

along the line of the fault, approximately equivalent to

1000 years of accumulated movement in one event. The

assessment showed that the current routing of MEIDP could

accommodate this movement without overstressing the

pipeline, and with only a small increase in pipeline spanning

condition.

The Indus Fan

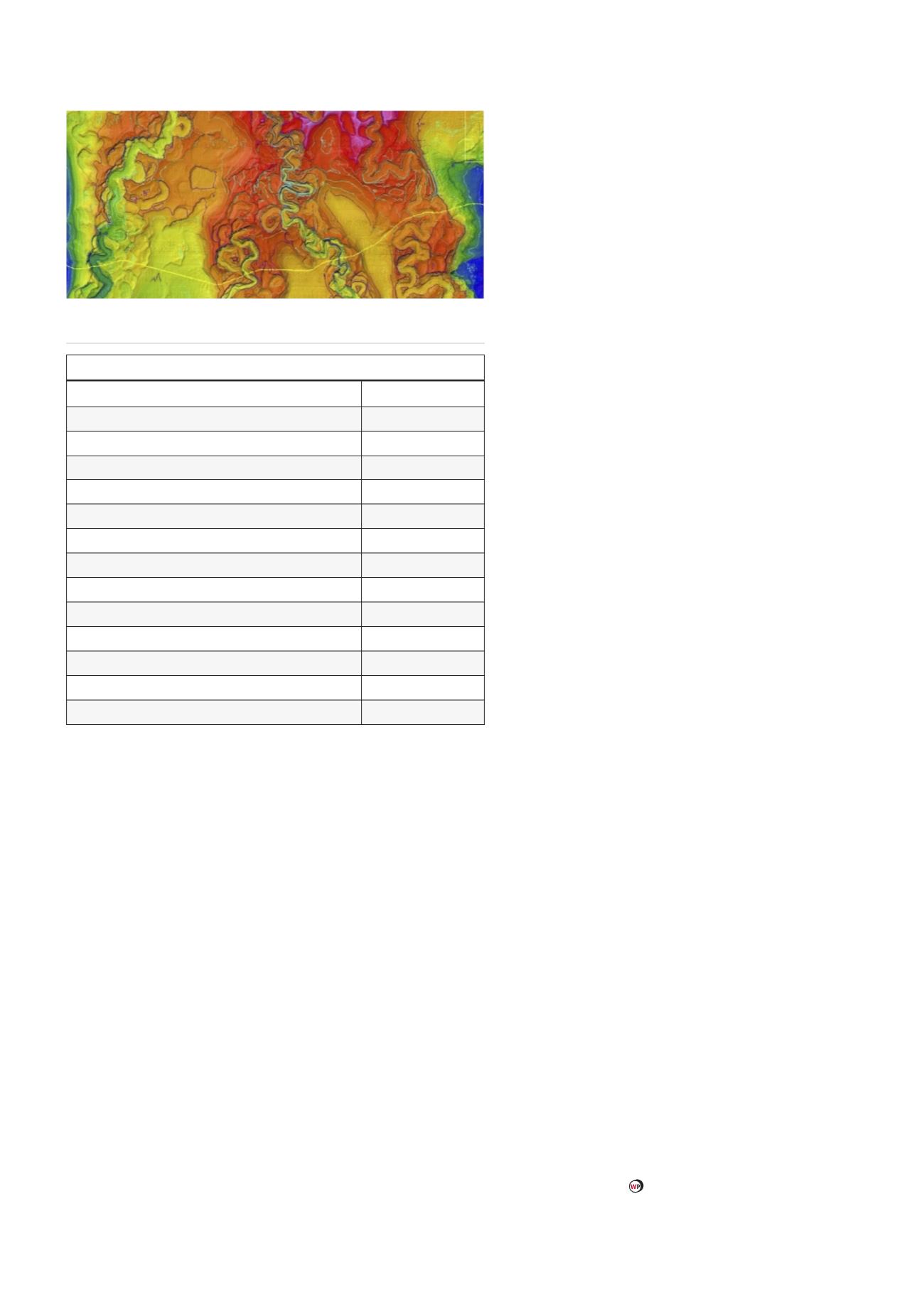

The meandering channel/levee systems of the main Indus

Fan region generally run north to south, and are flanked by

deep sea basins to their east and west. These channel/levee

systems are characterised by central channels, adjacent

stepped terraces, and abandoned loops. The abandoned

loops are partially filled by sediments spilling over from the

active channels. The abandoned channel loops and terraces

associated with the active channels can be clearly seen

in Figure 7. Water depths as MEIDP crosses the Indus Fan

range from 2140 m at its shallowest point, to 3200 m at its

deepest.

The pipeline route crossing crosses five turbidity current

channels. These channels are up to 200 m deep and have

side slopes of up to 25˚.

The pipeline route defined during the RMS has been

used to perform an initial bottom roughness assessment

(stress state and spanning condition) of the Indus Fan. The

assessments show that an acceptable route across the Indus

Fan can be achieved. However, significant spans of up to 6 m

height may be present.

Project schedule

The project goal is to achieve first gas in 2027, to coincide

with the expected growing shortfall in India’s natural gas

needs and the tightening of the LNG market. The project can

be executed in six years if brought on fast track with active

government support, since substantial preparatory work has

already been undertaken and continues. Pipeline construction

will occur over a two year period.

Summary

The body of work performed by Peritus International and others

for SAGE has proved the technical feasibility of the MEIDP

project. This has been formally confirmed by DNV GL issuing a

statement of feasibility. The feasibility has also been confirmed

by Engineer India Limited (EIL).

The technology to undertake the design, manufacture the

linepipe, and lay deepwater pipeline is now operational. Mills

in India, Japan, Europe and China are both capable and keen to

supply the high-quality linepipe required for MEIDP.

SAGE believes that the technology and commerciality of

the MEIDP project is proved and is ready to invest in a detailed

marine survey and offshore and onshore FEEDs, which will cost

approximately US$60 million. However, as with all transnational

gas pipelines, the MEIDP project needs strong diplomatic and

political support from the associated governments before it can

move to the next phase.

Figure 7.

Indus Fan abandoned loops and channel terraces along MEIDP

route.

Table 2. Project schedule

Event

Date

Award reconnaissance and metocean surveys

February 2020

Commence reconnaissance survey (for deviation)

April 2020

Commence metocean survey

April 2020

Award onshore and offshore FEED

January 2020

Award detailed surveys

April 2020

Final investment decision

December 2021

Award linepipe contract

December 2021

Award onshore and offshore EPIC

June 2022

Start offshore construction

October 2023

Start compressor station construction

April 2024

Complete offshore construction

April 2026

Complete compressor station construction

June 2026

First gas

December 2026

28

World Pipelines

/

MARCH 2020