•

Statement of feasibility – EIL (2017).

•

Technical qualification plan – Peritus International and

DNVGL (2018).

•

Japanese and European pipe mill qualification –

JFE (2018/2019), Europipe (2018/2019).

•

Update of detailed marine survey definition and SOW –

Peritus International (2019).

MEIDP system

The MEIDP project consists of three components: 1) the Middle

East compression station (MECS) in Oman, 2) an offshore

pipeline from Oman to India, and 3) the Gujurat pipeline

receiving terminal (GPRT) in India.

The design average annual throughput of the pipeline

is 10.3 billion m

3

/y, which equates to a peak throughput of

30.96 million m

3

/d, allowing for downtime and maintenance.

The system will be designed with a maximum design pressure

(at the MECS) of 400 barg and a minimum receiving pressure (at

GPRT) of 50 barg. A simple representation of the battery limits is

presented in Figure 2.

Offshore pipeline

The MEIDP has been designed to meet the requirements of

DNVGL-ST-F101. The pipeline’s starting point is at the MECS

located near Ras al Jifan, on Oman’s east coast, and it ends

at the GPRT near Porbandar in the south of India’s Gujurat

state. The pipeline will have a constant internal diameter (ID)

of 610 mm (24 in.) and a wall thickness that varies between

32.9 - 40.5 mm, depending on section and water depth. The

steel grade will be DNVGL SAWL485 FDU – which is an

API5L X70 equivalent. The pipeline route length for the base

case route is 1200 km, and the deviated route avoiding the

Pakistan side of the Oman/Pakistan ECS claim median line is

1300 km. The maximum water depth along the route (base or

deviated) is 3450 m, with more than 85% of the route being

deeper than 2500 m, as illustrated in Figure 3. The estimated

linepipe steel tonnage is between 800 000 - 880 000 t,

depending on the route adopted.

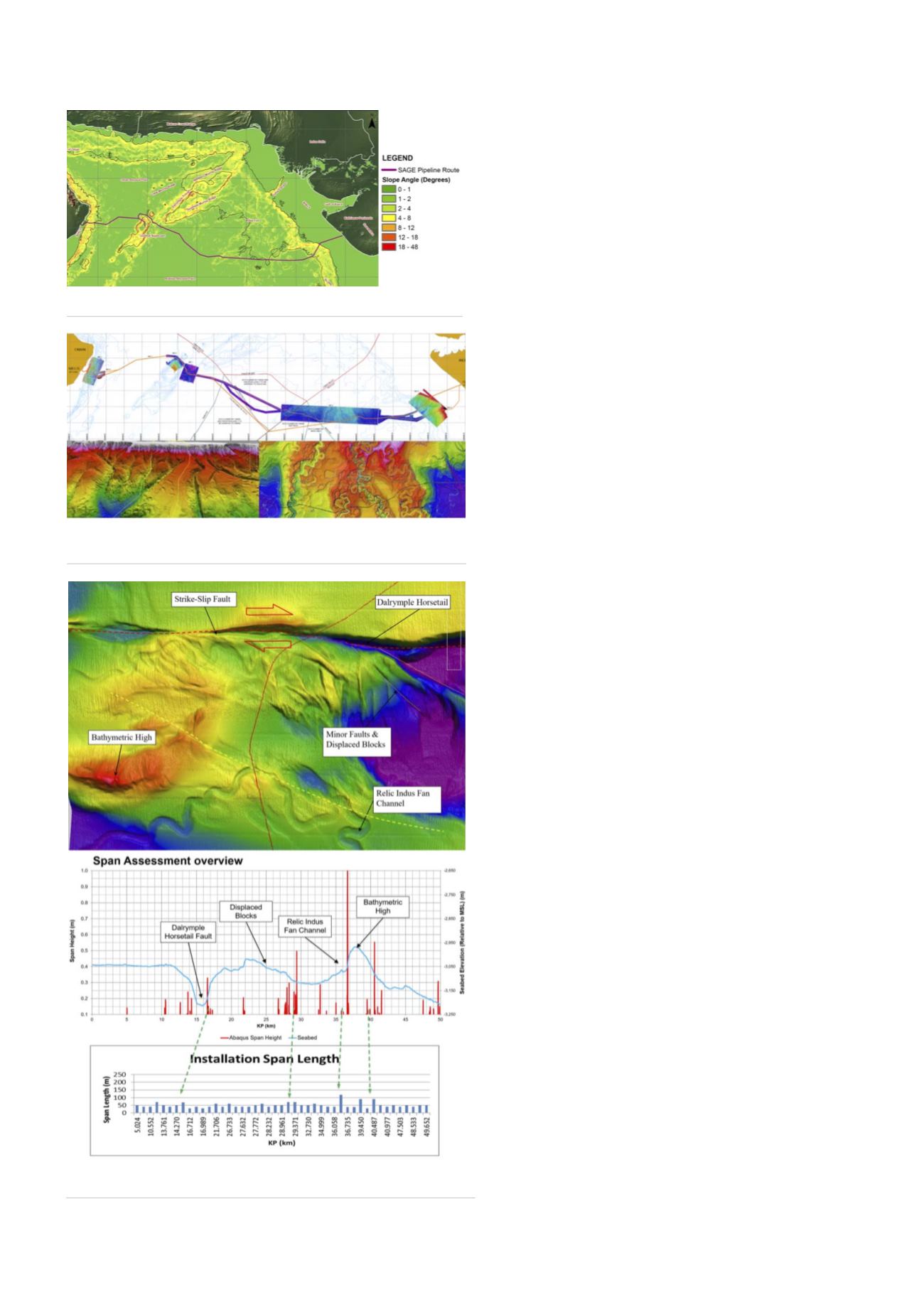

The MEIDP route crosses several geological regimes

(Figure 5). The dominating features of the Oman shelf are

hardgrounds with coral structures covered by a thin blanket

of fine soft sediments, likely to be very soft to soft calcareous

sandy clay/silt. The Oman slope is dominated by complex gully

and channel systems reaching down to the continental rise

where multiple slump deposits are seen. The seabed of the

Oman Abyssal Plain is smooth and featureless, covered by very

soft to soft calcareous clay/silt. The route also crosses multiple

faults at the Owen Fracture Zone (OFZ) and the associated

Dalrymple Horsetail. The pipeline route in the Upper Indus Fan

crosses large channel-levee systems originating from turbidity

mass movements derived from significant historical sediment

inputs of the Indus river.

Geohazard challenges

A preliminary geological and geohazard route assessment has

been performed by Fugro. This assessment identified expected

hazards. The larger identified hazards are presented in Table 1

and Figure 4.

Figure 5.

2013 reconnaissance survey (Oman continental slope and

Indus Fan).

Figure 4.

Map of seafloor slope angle and features.

Figure 6.

MEIDP route across Owen Fracture Zone.

26

World Pipelines

/

MARCH 2020