field operations. Cortez Subsea, alongside MCS and DeepTech

combined, offers a fully integrated service including advanced

remotely operated vehicle (ROV) equipment, data capture, and

smart delivery for subsea pipeline inspection which can be quick,

clean, and safe.

The company’s aim is to improve conventional pipeline

inspection. Its pipeline inspection services are performed with

both work-class and mini ROV systems, and include a range of

activities such as general visual inspection, cathodic protection

measurement, flooded member detection, and dimensional

survey.

This technology is designed to bring pipeline inspection into

the digital age. ROV systems are linked to a 3D photo-realistic

cloud to produce detailed, 3D imagery just like the human eye,

but without the human risk. Cortez Subsea’s Pipeline Commander

software automatically logs the streams of digital data from

the ROV, which can then be easily accessed and shared. This

technique is diverless, and digital reporting makes the process

quicker and more efficient. It also requires minimal equipment,

which can significantly reduce costs.

Research and development

These innovations are discovered through continual investment

in research and development (R&D). Cortez is committed to

investing heavily in R&D, and the group spent a combined

US$2.5 million on innovation in 2018, with 30% of staff being

dedicated to the cause. This is clearly a significant investment, but

the importance of R&D cannot be over-emphasised as each and

every aspect of exploration and production is impacted by it.

Overcoming obstacles

One of the most exciting benefits of collaboration is the

opportunity to overcome obstacles together, when it might not

be possible independently. Welding is the predominant method

for fabricating pipe systems across the subsea industry. However,

there are several applications where traditional welded pipe

connections become inefficient, uneconomic or impossible.

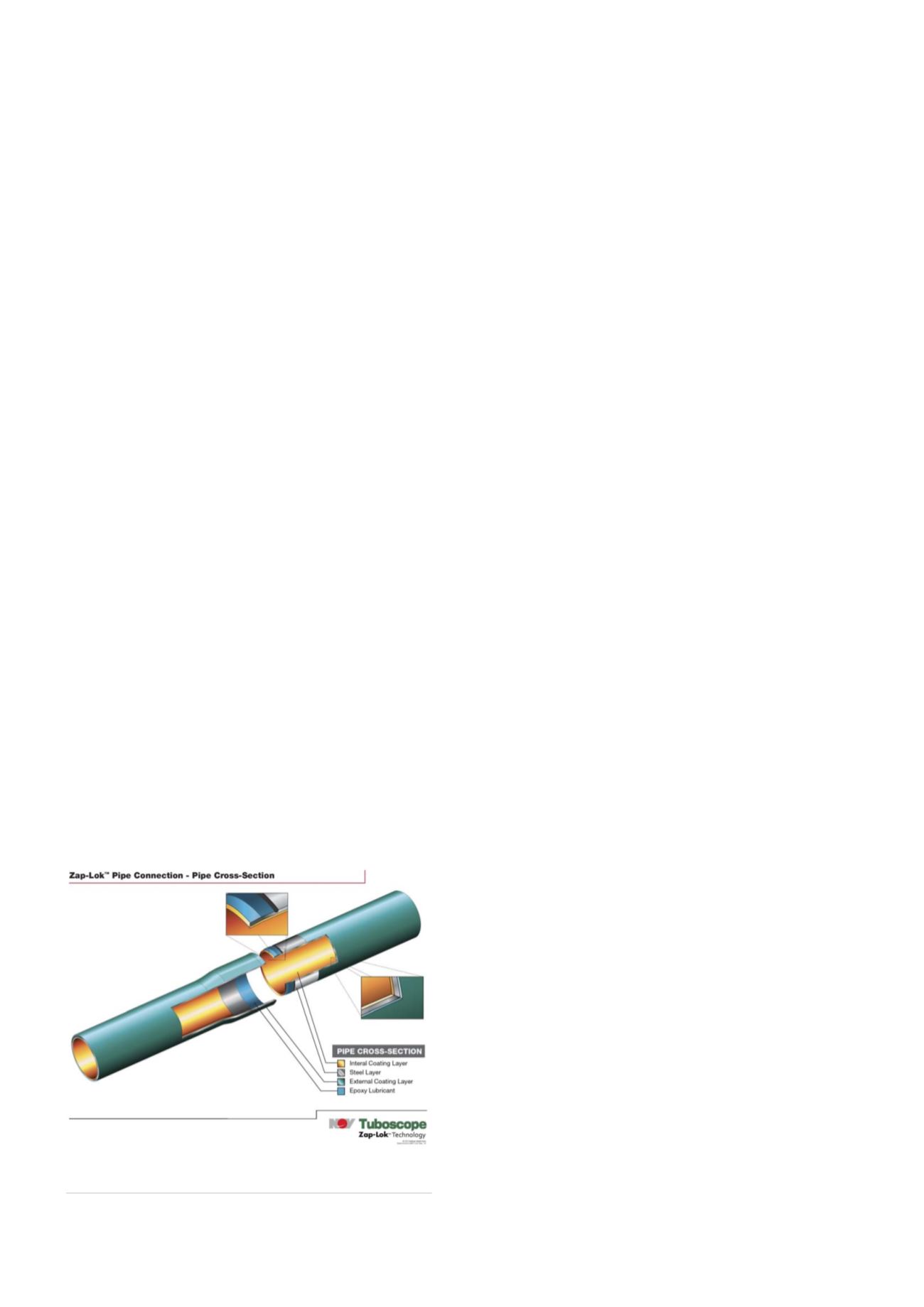

Cortez works with NOV-Tuboscope to deliver Zap-Lok

TM

mechanical connectors to the offshore market for subsea pipelay

– these are designed to be fast, strong and cost-effective. In

shallow water up to 300 m, rather than using traditional welding

methods, mechanical connectors are formed on carbon steel

pipes and are pushed together to make joints stronger than the

steel itself. The Zap-Lok technology is proven, with more than

7000 km of subsea hydrocarbon pipelines installed worldwide

and zero recorded failures in operation of over 70 000 joints.

These mechanical connectors are coupled with the Cortez

designed and patented Modular Pipelay System (MPS®) to offer

a weld-free, semi-autonomous process capable of laying up to

5 km/d in comparison to conventional pipelay, which achieves an

average 1.5 km/d. Easily installed on smaller, non-specialist vessels,

the Cortez system requires 50% less crew. Less manpower and

boat time means the carbon footprint is reduced, whilst no hot

work or radiography means it is designed to be safer.

Zap-Lok and MPS were designed specifically to satisfy the

fast-paced, cost-conscious requirements of today’s pipeline

construction projects. Fears of being the first to adopt the

technology are alleviated, as it has a more than 30-year successful

history in other oil and gas regions for thousands of miles of

flowlines, gathering lines, water lines and aided-injection systems.

Change is the only constant

Development of technology products and their application

continues on a daily basis. Whilst sometimes these can be

specific enabling technologies, it is mainly about optimising

current technology from within and outside of the sector.

Environment, production reservoir, asset integrity, and

development design are all driving the desire for new technology.

A prime example is the advances in ROVs. No deepwater

development can take place without one. The heavy reliance

on ROVs has resulted in intense pressure on manufacturers and

operators to regularly progress the technology of these machines,

and their associated equipment, forwards to ensure reliance,

operability, and flexibility in all subsea operations.

Reduce, reduce, reduce

The oil and gas industry increasingly wants to create an

environment in which people are both safe and proud to work.

The advancement of new technology is one way to ensure

that increasingly stringent environmental targets are met and

exceeded.

The International Maritime Organisation (IMO) has adopted

regulations and mandatory energy-efficiency measures to address

the emission of air pollutants from ships. The transition to a

lower-carbon future is underway, and the oil and gas industry will

have an important role in supporting this.

Among other efficiencies, Zap-Lok and MPS are designed

to reduce vessel size and time to shrink the operational carbon

footprint.

Queuing for second place

The reaction to advancements in technology has been interesting

to observe over the years. It can vary from reluctance to be an

early adopter through to all-absorbing, depending on the product

and application. The preferred position for companies is ‘first,

fastest follower’, indicating an aversion to be the first. Often a

technology development which is operator-sponsored through a

Figure 2.

Mechanical connectors aim to offer quick, safe and

clean pipelay.

30

World Pipelines

/

MARCH 2020