Incomplete surveillance of gas pipelines

In the audit conducted by CAG, it was observed that the

PNGRB mandated surveillance of the pipeline ROW through

means such as GPS, CCTV, satellite-based monitoring, and

aerial patrolling to detect abnormal activities around the

gas transmission pipelines. However, the surveillance was

incomplete in the case of the aforementioned pipeline

operator, as approximately 20% of its network lacks GPS-

based patrolling.

Thus, from the earlier discussion, the core element

which came to the fore was the non-adherence to standard

operating procedure, particularly with respect to gas

specifications, non-compliance to various directives of the

agencies responsible for safety of pipelines, and breach of

various provisions of pipeline integrity management systems

in place – besides non-compliance of the recommendations

by the PNGRB and CAG.

It is therefore required for entities to comply with

various provisions for pipeline safety, as consistent pipeline

failures have the potential to reduce the economic benefits

that can be derived from the transportation of natural gas.

It can dent the confidence of the public, which could slow

India’s direction towards a gas-based economy. Some of the

steps needed to make India’s gas pipeline industry robust are

outlined as follows:

)

Given the high number of pipeline ruptures due to

third-party damage, there should be a well-articulated

framework akin to the ‘Common Ground Alliance’ of the

US, wherein there should be one number such as ‘811’

which is used as an emergency number by the third-

party before digging the pipeline, e.g. ‘Dial before you

dig’. This has been recommended by the PNGRB on

several occasions at the time of any reported pipeline

failures due to third-party damage. Moreover, excavators

should be brought under stringent regulation to take ‘no

objection certificate’ from the pipeline operator before

initiating any activities around the pipelines, as is the

case in the Middle East.

)

To deal with pipeline failures in the form of corrosion,

each pipeline operator should make optimum use of

several integrity assessment tools available as per the

integrity management system, such as ILI, cathodic

protection monitoring, and surveillance – including

ground surveys and unmanned aerial vehicles, particularly

at critical and inaccessible stretches.

)

Regarding dealing with corrosion, it is observed that there

is a competency gap against the job roles of personnel,

which needs to be filled through planned training. This

training should take care of knowledge of various modes,

methods, and conditions of corrosion, and the design

of an integrity management system. Further, taking steps

during the design stage itself, such as a selection of

correct material for the system, consideration of process

and construction parameters, determining its design life,

provision of corrosion allowance, etc., could help avoid

the majority of corrosion situations.

)

There is a stringent need for an intensive public

awareness campaign about pipeline safety, alongside

corporate social responsibility activities and local level

intelligence. If such awareness is made compulsory, it

would act as an additional layer of protection for gas

pipeline infrastructure.

Finally, as noted by the PNGRB 2012 regulation – Integrity

Management System for Natural Gas Pipelines – the

integrity management system should be regularly evaluated

and reviewed in line with changes not only in design and

operation, but also in both the physical and regulatory

environment in which the system operates, whilst also

supporting the operator’s integrity goals and taking full

advantage of improved technology.

References

1.

Business Standard, ‘

Pipeline dreams of gas-based economy: Hurdles in govt’s

$118-bn masterplan’, (2019).

Disclaimer

The views expressed in this article are those of the authors, not their companies.

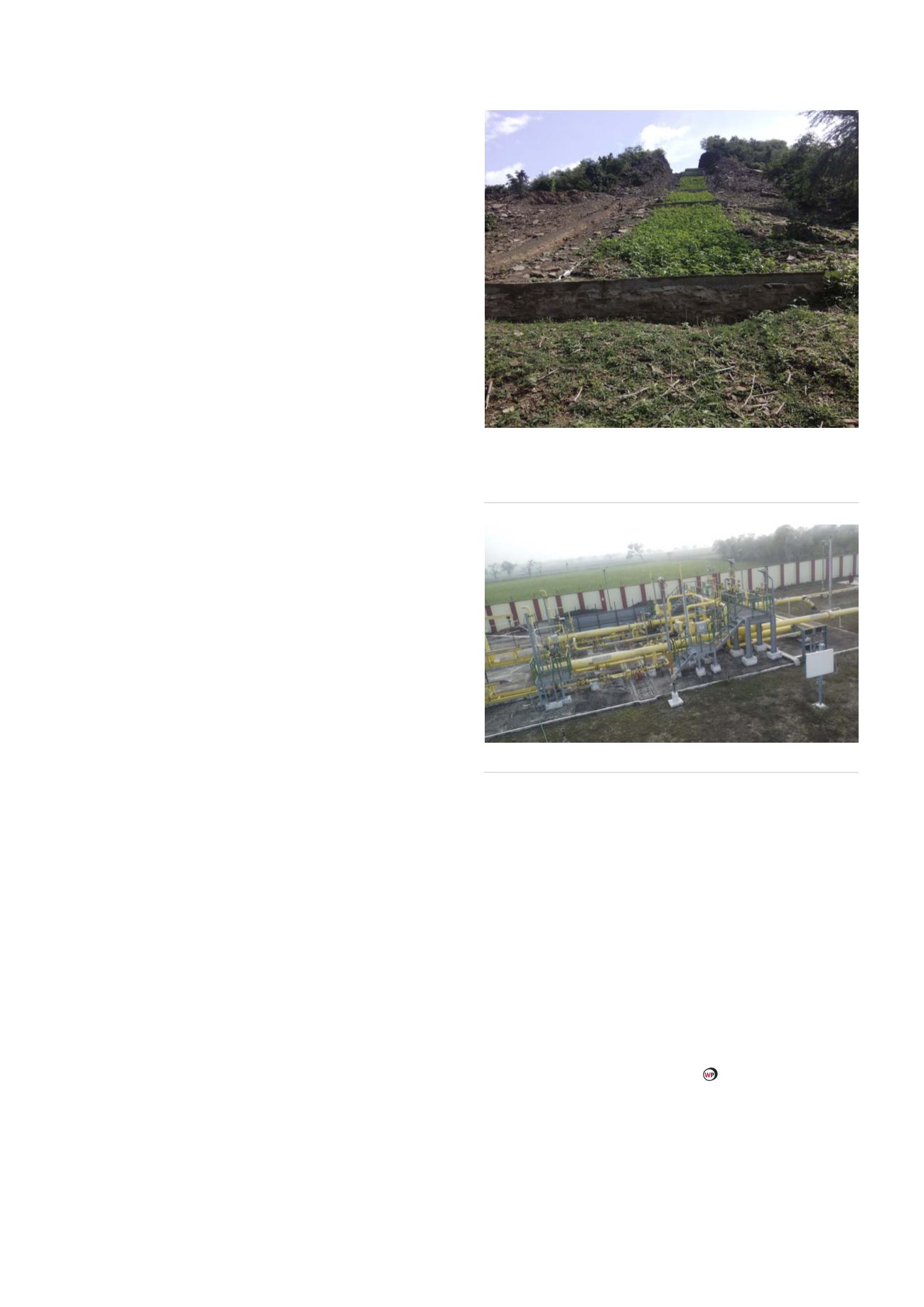

Figure 2.

SHPPL (Reliance Gas Pipeline Limited) 16 in. pipeline

crossing the Dhakarbari Hill (Madhya Pradesh-India) – soil

erosion protection on pipeline with vegetation and construction of

retaining walls.

Figure 3.

Intermediate pigging station facility.

MARCH 2020

/

World Pipelines

21