basis of performance specification of ILI systems. The

performance specification was made by modelling and pull-

through tests. Statistical analysis of the data was performed

with STATUS 5 Eclipse Scientific software.

Modelling

Simulations in CIVA software were performed to provide

constructive delay laws and beam computations, to enable

it to cope with the multiple materials and the complex

geometry of the prototype concept.

Beam computations were performed for different

media and pipeline diameters, and the correspondent beam

profile was assessed in predefined computational areas.

The developed system can extend the operating

envelope to lower velocity media. Therefore, the diameter

of the UT beam at the pipe surface can be established

according to the inspection requirements; Figure 2 shows an

example through a computational plane placed on the back

wall of a 28 in. pipeline, with light crude oil at 1350 m/s.

Pull-through tests

In March 2018, pull-through tests were performed in order

to establish the performance specification on a 28 in.

carbon steel test pipe spool with artificial manufactured

pinhole and pitting type defects, with medium density

crude oil (API gravity 26) as an inspection medium. Metal

losses were represented by two types of geometries: flat

bottomed holes (FBH) and hemispherical bottomed holes

(HBH).

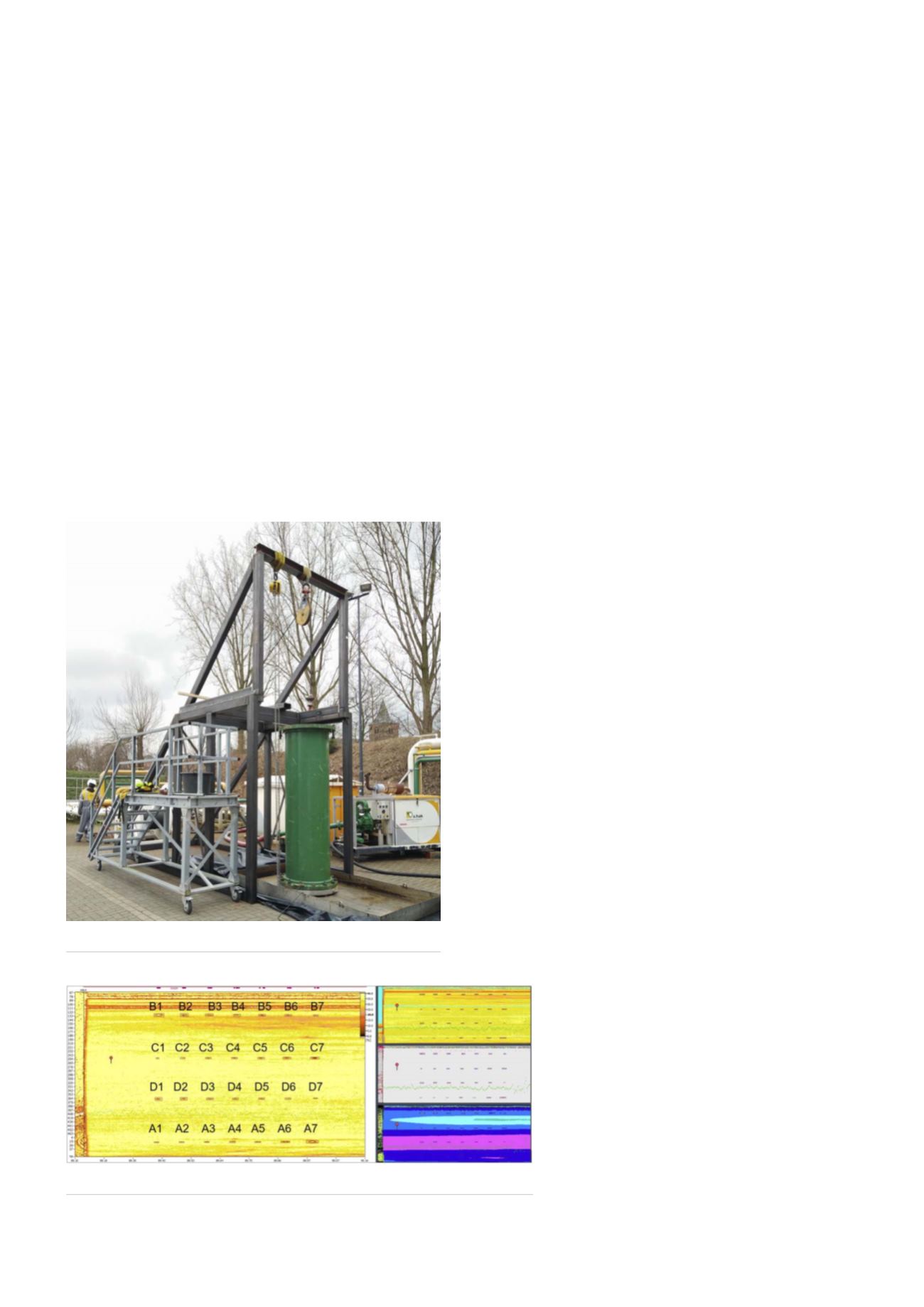

Figure 3 shows the test set-up for the pull-through tests.

12 runs were performed at an inspection speed of 100 m/h

– 470 measurements per revolution – enabling a measuring

grid of approximately 4.6 mm × 4.2 mm, circumferential and

axial, respectively.

Sizing of the detected flaws was performed by data

analysts. Figure 4 shows the C-scan images of one of the

pull-through runs performed.

Probability of detection and sizing curves

The probability of detection (POD) is the probability

that a feature with size a will be detected by the ILI tool.

According to the POF’s ‘Specifications and requirements for

inline inspection of pipelines’ (2016), two features can be

extracted:

)

A 90/50 (a90) is the feature size at which the average

POD is 90%.

)

A 90/95 (a90/95) is the feature size at which the lower

95% confidence limit of the POD is 90%.

All metal losses, represented by FBHs, were detected

in all the runs. These are not considered in Figure 5. The

two smallest HBHs were not detected, both internal and

external (Figure 5).

Regarding metal losses, for FBH, the tool has a depth

sizing accuracy of

±

0.1 mm, length sizing accuracy of

±

7.3 mm and height of

±

12.2 mm, with a 95% confidence

level. For HBH, it has a depth sizing accuracy of

±

0.2 mm,

length sizing accuracy of

±

5.4 mm and height of

±

10.8 mm,

with a 95% confidence level.

Case study

The tool developed has been deployed over several

projects. One of these projects was for a European pipeline

owner.

Pipeline characteristics

The pipeline had the following characteristics:

•

Diameter: 28 in.

•

Nominal wall thickness: 7.9 mm, 9.5 mm,

and 12.7 mm.

•

Length: 110 m.

•

Operational product: crude oil.

•

Inspection medium: crude oil.

As a part of the pig launcher, a validation

spool is installed. The spool contains artificial

metal loss defects, with known dimensions.

Figure 3.

Pull-through test set-up.

Figure 4.

Data acquisition C-scans.

66

World Pipelines

/

MARCH 2020