This allows additional performance, verification of system

performance prior to the inspection, and comparison of

the tool performance historic results.

Results

The inspection of the pipeline, covering a total length

of 112 m, was completed successfully in approximately

1.4 hours. The average velocity during the inspection was

96 m/h.

A total of 226 anomalies were reported, of which 216

were classified as lamination. The remaining 10 anomalies

are related to metal loss. All metal loss anomalies have

been further analysed, with Psafe and emergency repair

factor (ERF) calculated based on ASME B31G.

The results (POD and sizing accuracy) from the

validation piece inspection reflect the tool performance

characteristics as described.

Large diameter phased array tool

In previous inspections, labour-intensive preparations

were required to tune the system to the specific product

properties, which were not always known beforehand.

This resulted in significant project complexity and cost,

related to cleaning, drying, water supply, water treatment,

etc. Due to the improved and flexible acoustic design of

the phased array tool, this is no longer required, because

the acoustic properties of the tool can be calibrated and

tuned to the specifics of the product in the pipe on-site.

)

For any pipeline of 20 in. and above, the system can be

integrated in a single bidi body, similar to a cleaning

pig.

)

The system can be deployed as a bi-directional tool:

a single access point can be used for deployment and

retrieval.

)

The small sensor head makes it possible to cope with

tight bends, tees, reductions, etc.

)

A simple, small pig launcher can be used.

)

Phased array technology increases flexibility across a

multitude of products and product types (heavy and

light crude, diesel, naphtha, etc.).

)

Optional availability of optical fibre for data

communication during the inspection run; the data

can be reviewed for position information and quality

assurance, and inspection parameters can be fine-

tuned.

)

Inspection in product is a significant time and cost-

saver for the out-of-service period of the pipeline.

)

The tethered data collection allows for instant

feedback on the inspection quality, which allows for

swift insight into the success of an inspection run.

)

Intero LDUT makes it economically feasible to pig

short and difficult-to-pig pipelines.

)

No water usage, less cleaning, waste water (treatment),

etc.

Despite the fact that the inspection was executed

in crude oil, the inspection performance on the

validation spools was improved, compared to historic

verification runs with a conventional tool in water.

Conclusion

A large diameter inspection tool has been developed

based on the internal rotating mirror principle that

allows the pipe to be investigated 360˚, enabling the

establishment of both the measuring grid and beam

profile according to the inspection requirements.

The tool is designed to provide robustness,

flexibility (short radius bends, offtakes) and versatility

(product independency: any fluid). With bi-directional

capabilities in a cleaning-pig form factor, it can be

deployed in a cost-effective manner for short and

difficult-to-pig pipelines.

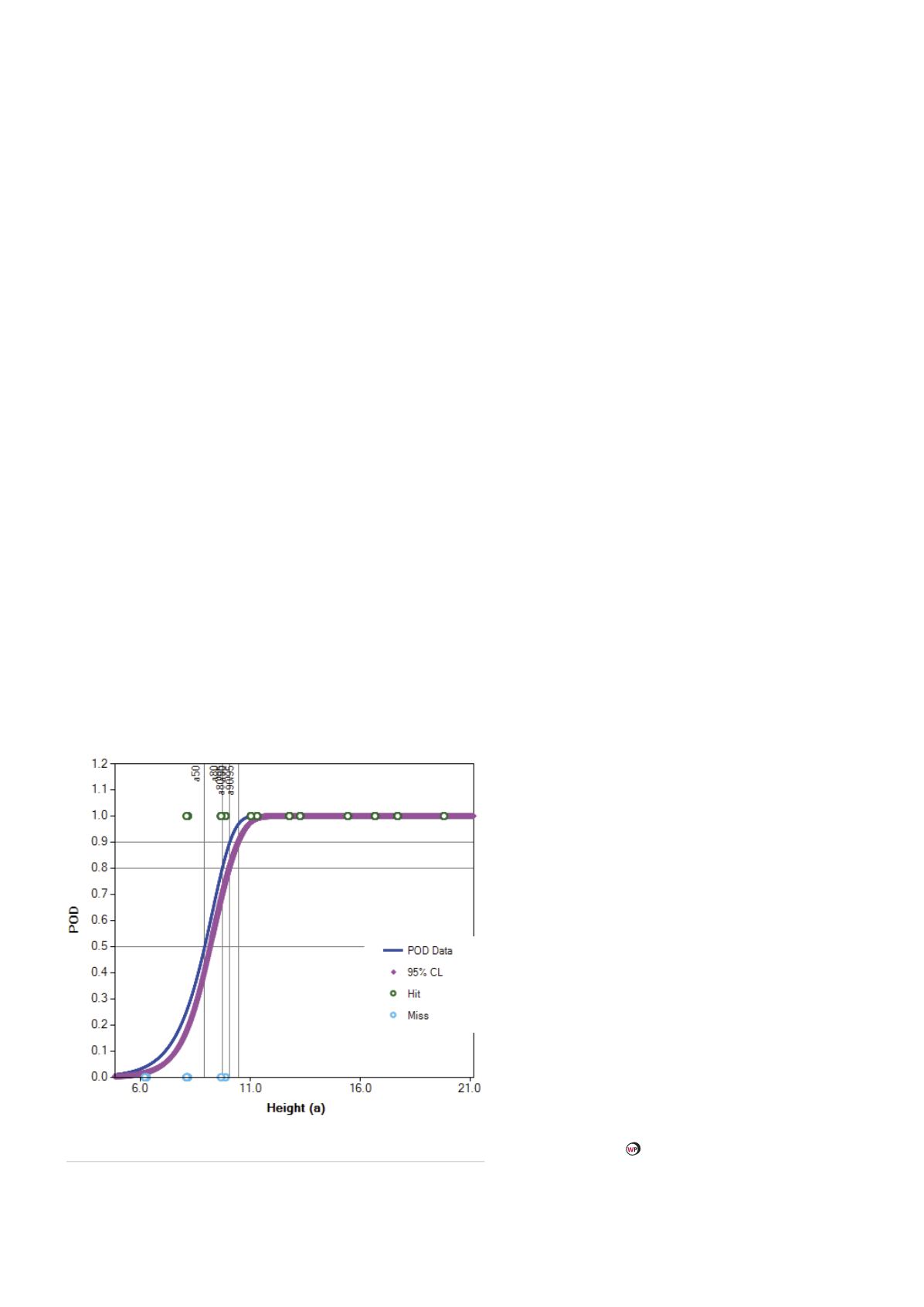

The probability of detection and sizing accuracy

has been validated, both by simulations and pull-tests.

This has been confirmed on a real-life project.

All metal losses, represented by FBHs, were

detected in all the runs. The a90/95 is established at

10.5 mm for HBHs.

Figure 5.

Probability of detection curve for HBHs.

68

World Pipelines

/

MARCH 2020