and techniques can be utilised, including ultrasonic testing

(UT).

The cost-effective ultrasonic inspection of large

diameter pipelines has been a challenge for decades in

the industry, and Intero Integrity has been working on an

improved inspection system for this case.

Scope

Intero operates inspection tools based on UT to determine

the remaining wall thickness of pipelines. In the range of

services provided, the inspection of large pipelines presents

several technical and operational challenges.

To enable inspection of these pipelines, clients

frequently require the inspection to be conducted without

exposing their pipelines to a different product. This

presents several challenges as these large pipelines may

contain multiple liquid products at different temperatures,

and frequently their acoustic properties cannot be

characterised prior to inspection.

Characterising the acoustic properties beforehand is

typically only possible for some pure refined products,

while for others – such as crude oils – it is not possible

because of the wide variation produced from different

oilfields, or various blends available. Furthermore, their

properties can vary significantly due to the temperature of

the inspection medium.

Objective

The main objective was to develop a flexible, safe, and

cost-effective system based on UT, that could work in

various inspection media (products), increase the sensitivity

and resolution of existing tools, and be capable of

inspecting pipelines ranging from 20 in. up to 64 in., with a

form factor of a typical bi-directional cleaning pig.

System description

This inspection system relates to thickness measurement

through phased array ultrasonic testing (PAUT), enabling

corrosion mapping of pipelines.

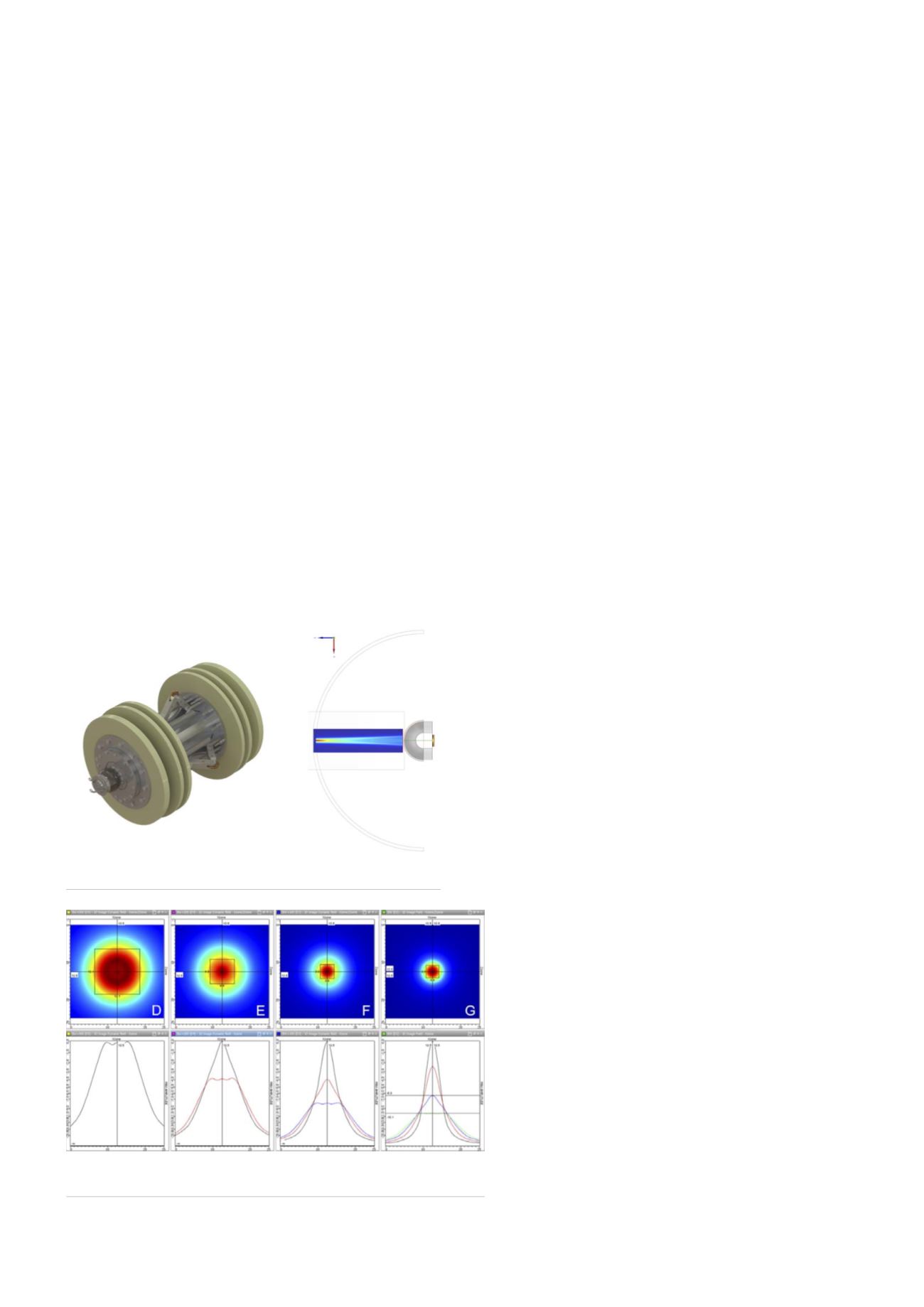

The concept is based on the standard Intero Piglet®

system, deploying an autonomous pigging system, with an

optional optical fibre tether to allow for real-time data

review during the inspection. However, it is improved with

an annular ultrasonic phased array transducer enclosed in a

spherical housing. The rotatable mirror arrangement based

on the internal rotating mirror principle (IRIS) allows the

pipe to be investigated 360˚ with an adjustable measuring

grid.

Some of the benefits of phased array technology

over conventional UT derive from the ability to control

beam shape on transmission, and increase the sensitivity

on reception. Annular array transducers have unique

characteristics which make them suitable for this

application, as they can focus at a predetermined distance,

producing a symmetric and circular beam profile.

Crude oils are typically attenuative media which exhibit

a natural high frequency filtering effect. Conventionally,

overcoming the frequency dependent attenuation effects

was achieved by outputting more energy, lowering the

inspection frequency, and transmitting a longer pulse at the

cost of lowering the axial resolution.

Traditional single-pulse excitation can be replaced by

long coded pulse excitation, which can extend the pulse

duration instead of increasing the signal pulse amplitude. In

this way, the average transmitting energy can be increased,

overcoming severe attenuation by the inspection medium.

The application of frequency modulation signals, also

known as ‘chirps’, consists of transmitting a wide band

frequency modulated signal that is cross-correlated with

a reference in order to be able to resolve in time the

returned echoes. The correlation process restores axial

resolution and increases SNR.

The ‘chirp’ signals are also less susceptible to

the influences of coatings, contaminants, debris or

impurities in the product.

The signals applied are dependent on the

application and the transducer used. In some

applications the broadband electrical signal applied to

the transducer includes energy up to 10 MHz; for other

applications, the energy may be restricted to 3.5 MHz or

less.

Performance specifications

The Pipeline Operators Forum (POF) 2016 and the

API1163 standard provide guidelines for defining the

Figure 1.

LDUT Piglet

®

.

Figure 2.

Computational plane placed on the back wall of a 28 in. pipe

(beam profile at -6dB).

64

World Pipelines

/

MARCH 2020