24 hours a data quality assessment was conducted and presented

to the operator, which includes a human-based evaluation of

the data from a level three data analyst to confirm the quality

of the data. The data was confirmed to be 100% within the

pipeline operator’s specification and 100% sensor coverage of all

technologies. Over the next 45 days, the data was analysed, and a

final report was presented.

Tool capabilities

With ENTEGRA’s UHR combination tools, the long seam weld

of a pipe is found to be much more visible, identifiable, and

measureable. Like many other threats, detection of corrosion on

the long seam of this 30 in. pipeline was critical. Not all corrosion

on or along the long seam weld is treated equally, but seeing it

and characterising it as coincidental or preferential is a priority

and helped this operator make decisions on what they needed to

address. Because the long seam can be seen in the data, the metal

loss may also be assessed, and the pipeline operator can prioritise

action of the anomalies, down to the pinhole sized metal loss.

Not previously reported, Figure 2 is a screenshot of a pinhole

found on the long seam. The specific pinhole found was unique

because it was missed by conventional handheld UT devices

on the first attempt to locate. After the handheld UT device

failed to locate the pinhole, the operator deployed more precise

NDE methods, and it was found and validated by using X-ray

equipment. Once validated, the pipeline operator was able to

prioritise and address it.

Due to the enhanced sample rate and sensor density of

ENTEGRA’s UHR combination tools, the company provide

a pinhole specification to help pipeline operators detect,

characterise, and size pinholes in their pipelines. This was a

deliverable the previous ILI vendor was not able to provide, and

was becoming increasingly important to the operator to detect

and size. Figure 3 is a screenshot of the X-ray of that same pinhole

in Figure 2, found on the long seam of the pipe. This defect was

found to be approximately 3.5 mm in diameter and directly in the

long seam weld.

UHR data also enables the detection of seam variations.

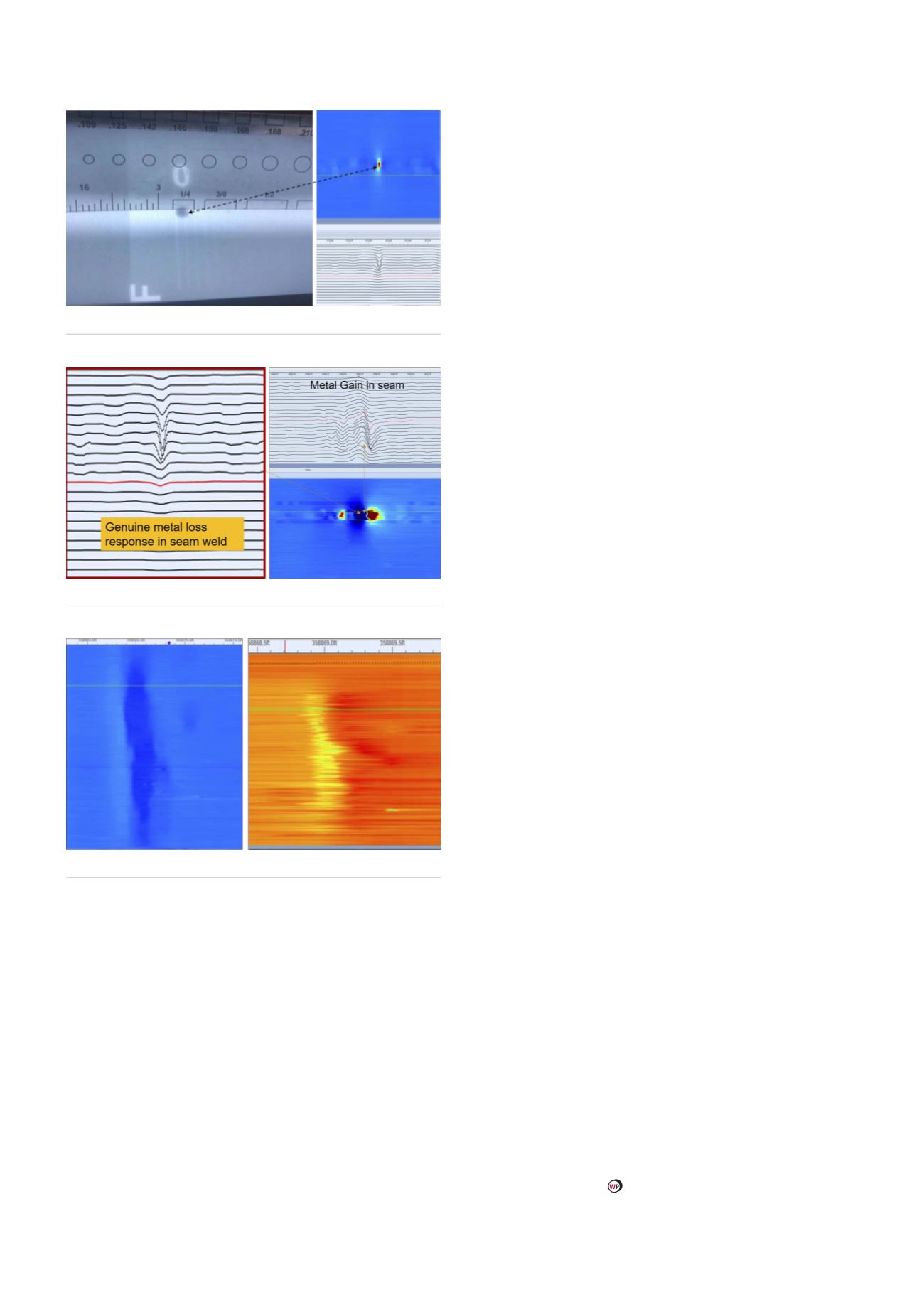

The image on the left in Figure 4 exemplifies what a genuine

metal loss signature looks like in a seam weld. To the right is

what a metal gain looks like in the seam. The previous ILI vendor

reported a 58% metal loss depth, whereas ENTEGRA’s UHR data

called out a metal gain and rough seam welding. The detection,

sizing, and prioritisation of this anomaly was a critical find for the

pipeline operator, given the expansive HCAs this pipeline runs

through.

Detection of hard spots is another capability of ENTEGRA’s

UHR tools and expert data analysis team. Hard spots are changes

of hardness of the pipeline in localised areas, and are of specific

interest in this 30 in. pipeline. These hard spots can derive from

the manufacturing process or general changes in the chemistry of

the steel. As the metallurgical values of hard spots are different

and unique, they are prone to failure such as cracking. The

detection of hard spots in this 30 in. pipeline in or near HCAs was

a priority. Figure 5 illustrates a hard spot that was found.

Conclusion

In conclusion, the ILI of this 30 in. natural gas pipeline was of

top priority for the pipeline operator because of its critical

distribution of product in multiple states, through multiple HCAs.

The operator chose multiple data set ILI tools, circumferential

ILI tools, and ENTEGRA’s UHR axial MFL/CAL/IMU combination

tool to inspect this pipeline for metal loss and other associated

threats. The overall speed profile utilising the UHR tool was

within specification, sustained 100% sensor coverage, and

navigated the back-to-back 1.5D bends without sacrificing data

quality.

Due to the combination of UHR axial MFL and UHR Caliper

data sets in conjunction with the MFL’s low field magnetic

capabilities, the pipeline operator was able to successfully and

accurately locate and address necessary threats such as hard

spots, dents with metal loss, and volumetric corrosion anomalies

down to the pinhole.

Figure 4.

Metal loss and gain signatures.

Figure 3.

X-ray of pinhole.

Figure 5.

Evidence of hard spot.

72

World Pipelines

/

MARCH 2020