specific (key) equipment available as this might be a

requirement in a project prequalification procedure, as part

of proving a construction companies’ capabilities. There

are, however, some major issues that have an effect on the

profitability of owning such specialised equipment.

Maintenance and service

In order to live through its useful lifespan – even when it is

not actually used on a project, thus also when there is no

actual revenue to cover the costs – machines have to be

maintained. If necessary maintenance (and service) is not

performed, this will result in extra costs when the machine

has to be prepared to actually go on a jobsite.

Project diameters differ

In gas pipeline construction, there is a range of common

diameters between 6 in. and 56 in. For welding tractors

this obviously is not a problem, but for pipelayers

and especially bending machines, this means that a

construction company has to have machinery available for

all the diameters from 6 in. to 56 in., sometimes in larger

quantities. Operating in a global market, it is also possible

that less common diameters appear, such as 21 in., 44 in.

or 52 in., and as a result it is nearly impossible for pipeline

construction companies to be prepared for the whole

range.

Project size increases

As explained, the current pipeline construction industry is

dominated by large-scale projects, making the highs and

lows in demand for this specialised construction machinery

more extreme. In such cases, a basic equipment fleet is not

sufficient to cover the total equipment needs for these

projects.

Projects become more uncertain

Long-term planning an equipment fleet becomes more

difficult because of these large projects, specifically due to

financing and geopolitics.

)

Financing: The larger the project, the more difficult

the financing becomes. Even with support funds of,

for instance, the EU, European Investment Bank or

Asian Infrastructure Investment Bank, this can result in

possible long delays.

)

Geopolitics: Many projects are no longer solely for

local or national use. There is even an active strategy

within the EU to construct interconnecting pipelines

between different countries to make energy supply

routes redundant and make energy supply more reliable.

When more countries are involved, this does not make

the viability of a project necessarily larger as different

countries might have different interests. This can result

in years of postponing or even sudden cancellation of

projects, bringing uncertainty in when to invest in what

equipment.

Technical developments

Although the technical lifetime of a machine is long,

the regulations and requirements regarding the machine

may change over time. This can be for specific clients

or projects, a change in national legislation, or even the

change of a global standard. When owning machines there

is the need to keep them up-to-date at all times. Examples

from recent years are the requirement for a ROPS on heavy

machinery and the presence of a load monitoring system in

a number of countries. However, in some countries it is not

necessarily about the technical condition or specification

of machinery; some countries simply block the (temporary)

import for construction equipment beyond a certain age.

An equipment owner

To summarise, owning pipeline construction equipment

is sometimes necessary but it can be costly, and planning

investments for such equipment (which often only has a

limited usability) has become increasingly difficult because

of the ever-changing conditions that come with extreme

large and complicated projects.

In all this, maybe the most crucial factor is that project

prices are under huge pressure. This has an effect on the

whole chain of construction, not only on contractors, but

Figure 4.

Different machines for different project diameters.

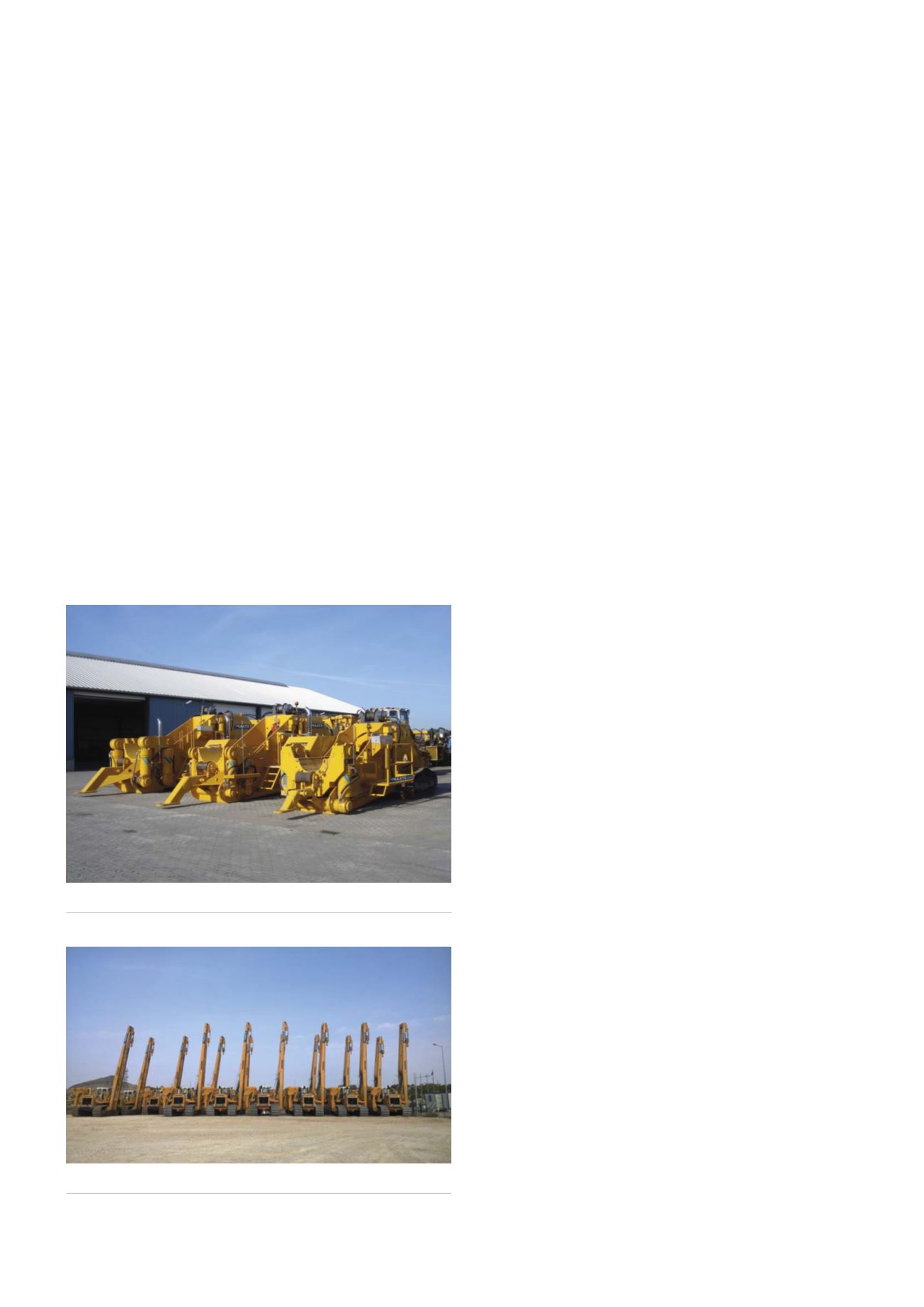

Figure 5.

Large projects require a high volume of machinery.

36

World Pipelines

/

MARCH 2020