The state of India’s pipeline failures

Even as India moves ahead with the extension of its gas

pipeline network for greater application of the cleaner fuel

option of natural gas, the June 2014 incident of gas pipeline

failure that led to 22 casualties in Andhra Pradesh is deeply

ingrained in people’s memories. As noted by the Petroleum

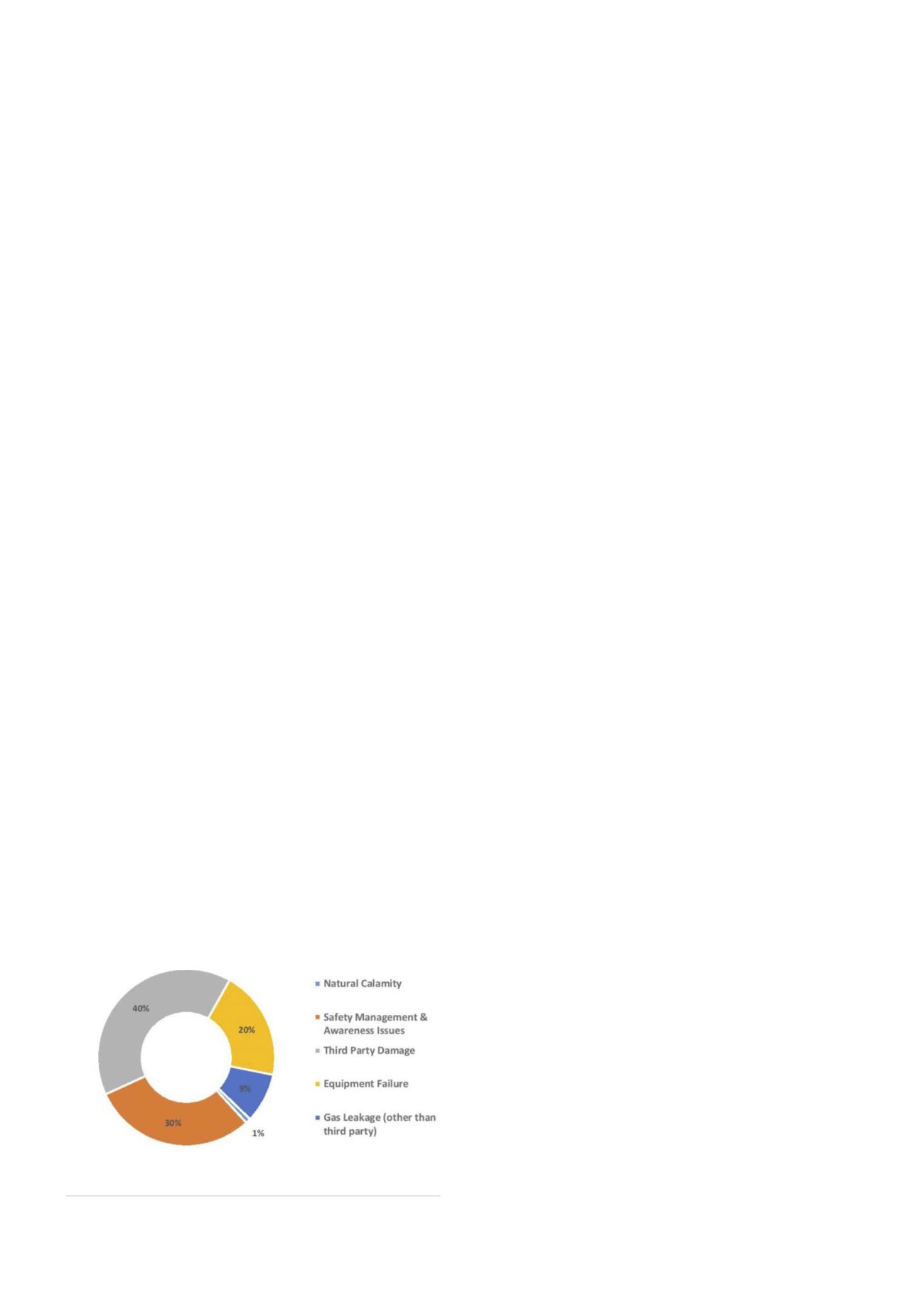

and Natural Gas Regulatory Board (PNGRB), the greatest

number of pipeline failures recorded in India is through

third-party damage (Figure 1).

India’s pipeline systems are still in a developing stage

and most of the pipelines are yet to reach a point where

replacement becomes important. However, there have been

incidents of internal corrosion due to non-incorporation

of gas specifications in the gas sale agreement and non-

installation of gas dehydration units (GDU), which has

reduced the life of pipeline assets, requiring them to be

replaced in four to five years’ time – as noted by PNGRB’s

probe of the Tatipaka-Kondapalli Pipeline (TKPL) incident.

Lessons from pipeline incidents

The TKPL incident is the most cited case of pipeline failure

in India, as it offers several lessons for other pipeline

operators. These lessons have prompted all pipeline

operators to take serious note of the recommendations

after the 2014 incident, besides implementation of directives

and regulations, more stringently than ever.

On 27 June 2014, the devastating fire at the state-

run gas pipeline operator, TKPL, occurred in Andhra

Pradesh, which killed 22 people and injured 18 others. The

18 in. OD × 7.11 mm pipeline was commissioned in 2001

by the operator to move dry natural gas to downstream

consumers from one of the leading upstream petroleum

company’s fields in India, but instead the pipeline carried

wet gas. This wet gas contained free water, carbon dioxide,

and sulfur that induced internal corrosion in the pipeline

and resulted in gas and condensate leaking to the surface.

When a stove was lit near the pipeline, the leaking product

caused a blast, which was followed by fire. As per the

PNGRB’s probe, the intensity of the explosion was such that

it fractured the pipeline, with an approximately 2 m length

portion ripped open and thrown 5 m away, impacting the

nearby dwelling units, houses, tea stalls, and coconut trees

spread over a 50 m radius.

After the probe conducted by the PNGRB and later by

the Comptroller and Auditor General of India (CAG) in its

audit of ‘Safety Preparedness of Oil and Gas Transmission

Pipelines’, the following causes for pipeline failure were

observed.

Corrosion

According to the PNGRB’s probe report, wet gas was in the

pipeline that was designed for dry gas, which therefore

did not meet the requirement of sub-regulations 5(5) and

8(1)(b) of the PNGRB’s 2008 regulation ‘Access Code for

Common Carrier or Contract Carrier Natural Gas Pipelines’.

The report also stated that the pipeline operator flouted

the declaration to the statutory authority as well as the

declared design basis by not providing GDUs at Tatipaka

and Mori, the absence of which led to an increase in the

pipeline’s corrosion rate.

In this regard, the pipeline operator did not comply with

the recommendations of the fitness-for-purpose report

(submitted in 2013 on the basis of an inline inspection

carried out in 2010); for example, the use of an effective

corrosion inhibitor in conjunction with operational

cleaning/dewatering pig runs whilst transporting wet gas.

Consequently, as per the CAG report, various pipelines

were corroded and needed replacing within a short period

of 4 - 10 years, against the designed operational life of

20 years.

Moreover, according to this report, where an intelligent

pigging survey is conducted to assess the health of a

pipeline through ILI of active pipelines for signs of metal

loss, corrosion or dents within 10 years from the date of

commissioning, the delay was found to actually range

from 1 - 17 years in the implementation of 66 pipelines

for piggable sections, and 1 - 4 years for non-piggable

sections in 46 pipelines – noticed in the case of the state-

owned gas pipeline operator. This was also non-adherence

to the PNGRB 2009 regulation: Technical Standards and

Specifications including Safety Standards for Natural Gas

Pipelines. Similarly, due to off-specification gas provided

by the aforementioned upstream company’s gas fields

of Ponnamada, Kesanapalli and Adavipalem, there was

extensive internal corrosion and reduction of pipeline

thickness, which led to fire breaking out on the Ponnamada-

Kadali natural gas pipeline. This resulted in huge damage to

nearby agriculture and property.

Third-party damage

As noted by PNGRB in its 2012 - 2013 analysis, third-party

damage has been the most prominent reason for pipeline

failure, with its number reaching as high as 2116. However,

there was an incident where a fire erupted in the state-

owned pipeline operator’s 12 in. natural gas pipeline, due

to gas leakage caused by a public works department

(PWD) contractor. The contractor was undertaking a soil

investigation survey by drilling at the affected location

without any intimation or permission from the pipeline

operator. This incident was the result of the absence of

technical supervision of both the operator and PWD,

Figure 1.

Causes of pipeline incidents. Source: PNGRB.

18

World Pipelines

/

MARCH 2020