March

2017

HYDROCARBON

ENGINEERING

76

reprocessed through the crude unit. Regardless of their

source, amines will increase the desalter brine pH. In the

simplest case, the increased pH can negatively impact

desalter efficiency. However, at higher pH, the amines

preferentially partition into the crude oil and are carried

downstream, where reaction with hydrochloric acid (HCl)

can form corrosive salts that cause damage in the

atmospheric tower and overhead system.

In addition to amines, calcium naphthenate presents

several well-known processing challenges in the refinery. A

salt present in calcium-contaminated crudes with a high

total acid number (TAN), calcium naphthenate stabilises

emulsions in the desalter. This causes upsets and

undermines the performance of downstream units such as

the wastewater treatment plant. Past the desalter, calcium

naphthenate can form a sludge that causes fouling in

towers, drums, heat exchangers, and furnaces.

Calcium can carry through into the atmospheric and

vacuum residue streams and feed into the fluidised

catalytic cracking (FCC) unit, where it reduces the activity

of the zeolite catalyst. Calcium can also end up in the

heavy fuel oil and coke products at the refinery, where it

degrades product value by increasing ash content.

Amines and calcium naphthenate cannot be easily

removed from the crude oil without adjusting the desalter

pH – typically achieved by the addition of acids to lower

the pH of the brine. However, most commodity acids, while

inexpensive, cause substantial secondary processing

problems. For example, citric acid reacts to form insoluble

calcium salts that can foul desalter internals, reduce

desalting efficiency, and lead to unplanned maintenance

outages. Sulfuric acid is often considered, but it

significantly increases the risk of both corrosion in

processing equipment and the deposition of calcium

sulfate scale. Acetic acid remains a popular option for

handling calcium naphthenates in the oilfield, but the

significant volumes required for

downstream programmes can

introduce several unintended

consequences. Not only does acetic

acid form emulsion-stabilising salts, it

partitions significantly to the crude oil

and increases corrosion in the

overhead. Additionally, it can cause

bulking and settleability issues in the

wastewater treatment plant.

A systems-based

approach

Baker Hughes developed its

EXCALIBUR contaminant removal

programme to overcome the negative

secondary effects of commodity acids

in desalter applications. The

programme lets operators manage

undesireable amines and process high

calcium crude oils without impacting

desalter reliability.

The technology includes a

water-soluble complexing agent that

is injected into the desalter’s wash water to lower the pH

of the brine and increase the solubility of contaminants in

the aqueous phase. The dissolved contaminants are

removed from the desalter with the effluent water drained

from the bottom of the vessel. The complexing agent

formulation avoids many of the processing problems

commonly encountered with commodity acids. A corrosion

inhibitor in the formulation mitigates corrosion risks in

crude unit desalting equipment, and specially formulated

emulsion-breaking chemicals help break down stabilised

emulsions and maximise crude oil dehydration and salt

removal. This minimises the carryover of harmful amines

and calcium contaminants into the desalted crude oil

stream. A scale inhibitor can be added to the formulation

to prevent the deposition of metal carbonates or sulfates

in the desalter effluent water removal system.

The programme was designed to provide the

aforementioned benefits while having minimal impact on

wastewater treatment activities. Improving oil and brine

separation in the desalter results in fewer oily solids,

phenols, and other organic acid species carried with the

brine. Unlike acetic acid, which is broken down by bacteria

to increase biomass and cause separation problems in the

wastewater treatment system, the technology’s

components readily biodegrade to release only CO

2

and

water.

By providing a lower, more stable pH in the crude unit

desalters, the technology allows refiners to improve plant

profitability by processing higher volumes of opportunity

crude oils, while also reducing operating and maintenance

expenses resulting from downstream fouling, corrosion, and

catalyst activity losses. It also allows the refiner to produce

higher value on-specification coke and heavy fuel oils.

The company’s contaminant removal technology has

helped refiners around the world successfully process

attractively-priced opportunity crude oils. Amine removal

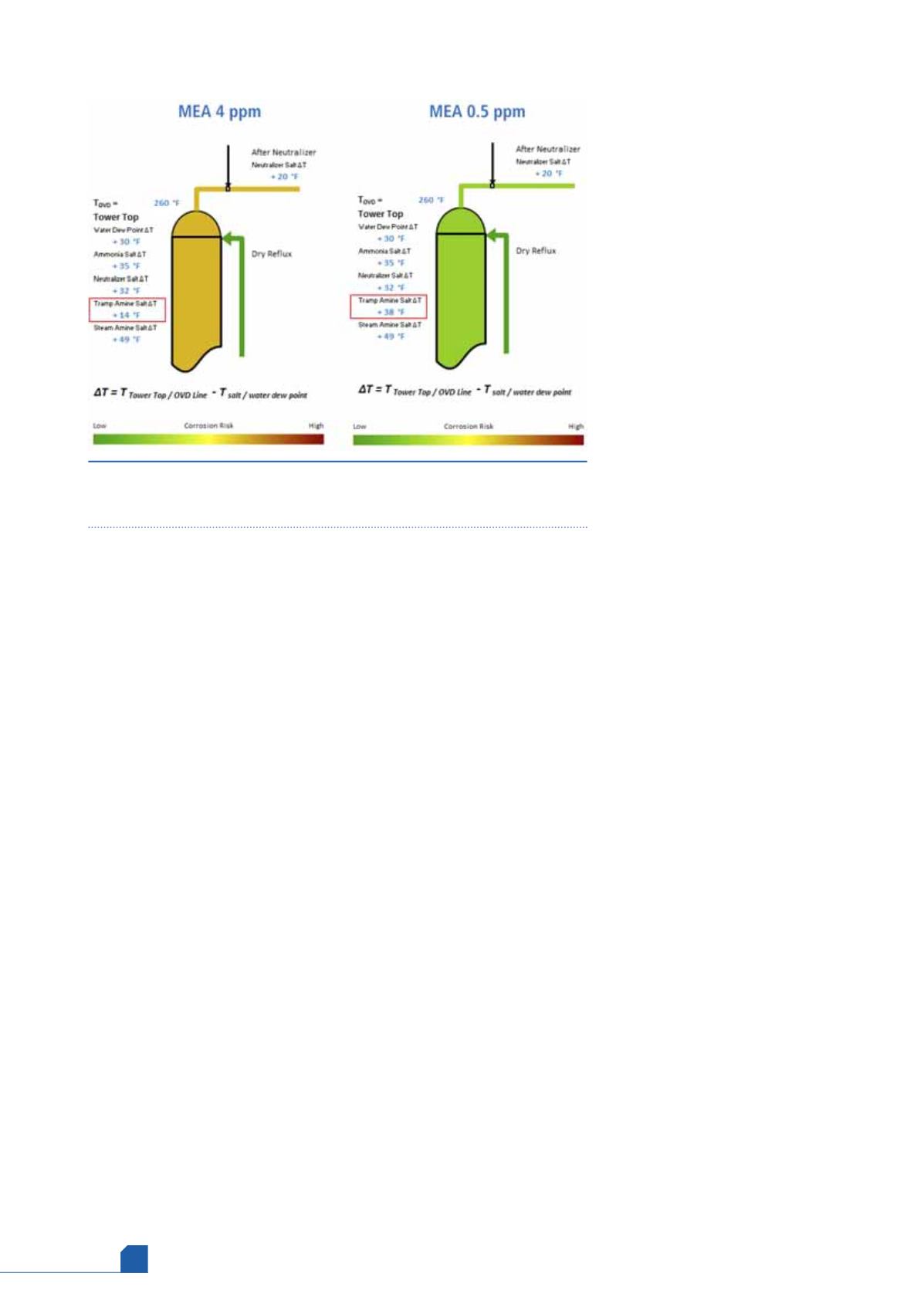

Figure 1.

Screenshots of the CRM output depict the reduced corrosion risk to

the top of the tower by reducing MEA from 4 ppm to 0.5 ppm in the desalted

crude.