March

2017

HYDROCARBON

ENGINEERING

82

other installed systems used for slurry oil clarification,

including mechanical filtration and settling tanks, the

refinery’s selection of the more efficient electrostatic

separation method proved paramount in helping to increase

profits and reduce waste throughout the refinery.

2

Slurry oil yields and properties

Slurry oil yields from FCC and RFCC are a function of the

severity of the operation. Yields are generally inversely

proportional to factors such as catalyst activity, temperature,

catalyst to oil ratio, etc., and are directly proportional to the

nitrogen, sulfur and asphaltenes (or alternatively vacuum

bottoms) content of the FCC feed. Slurry oil yields ranging

from approximately 1 to 2 vol.% for paraffinic feeds to as

much as 15 vol.% on RFCC feeds have been observed.

3

As might be expected, slurry oil quality is a function of

such variables as the properties of the FCC feed, severity of

the operation, type of catalyst, operating conditions in the

fluidised catalytic cracking unit (FCCU), etc.

4

The main concern with concentrated slurry is the

presence of asphaltenes, which are large chemical structures

with a high ratio of carbon to hydrogen. They contain nickel

and vanadium, which promotes coke generation when

deposited on FCC/RFCC catalysts. These are complex

structures and are difficult to describe chemically. Instead,

asphaltenes are defined by their solubility:

Materials that are insoluble in an excess of n-heptane (or

less often, n-pentane).

Those materials that are soluble in benzene.

When cracking residual feedstocks, the FCC catalyst pore

size is not large enough to allow the large asphaltenes

structures to enter the pores of the catalyst. The level of

conversion of asphaltenes in an RFCC unit is then a function

of the activity of the matrix of the catalyst.

4

If the FCC feed

contains significant levels of asphaltenes, as it would in

RFCC, the slurry oil will likely contain higher concentrations

of asphaltenes. When asphaltenes are present, nickel and

vanadium will be present on the catalyst and initially

deposited as part of the coke on catalyst and in the slurry as

metalorganic compounds. Catalyst particles in the slurry,

besides containing nickel and vanadium, also bring in sodium

and trap iron. Antimony and tin, which are used as metal

passivators, may be present on the catalyst or in the slurry oil

as well. Other FCC additives are used to control carbon

monoxide, sulfur oxide and nitrogen oxide emissions, and

metals traps may reside in the slurry oil, all of which contain

a variety of other elements that make removal extremely

difficult.

Recycling smaller micron particles is crucial for RFCC and

FCC fluidisation. BASF catalyst manufacture relies on a

certain amount of fines that are 45

μm

and smaller, for

proper fluidisation of the catalyst within the reactor. Note

that for these slurry oils, over 90% of the particles range in

size from 0 to 25

μm

dia. This means that very large holding

tanks and long holding times are required to meet higher

value product specifications. Some relief is obtained with

the use of settling aids

5

in this service. Sludge from slurry oil

holding tanks, however, is listed as hazardous waste by the

US Environmental Protection Agency (EPA), requiring more

frequent tank cleanings and the increased associated

expense.

4

Slurry oil particulate removal

technologies

Historically, holding tanks have been used to allow solids to

settle out of the slurry oil. The resultant decant oil solids

content are a function of the sedimentation tank design, the

physical characteristics of the slurry, the temperature of the

storage tank, and whether or not settling aids are used. In

addition to generating clarified oil, sludge results from the

settling process. Slurry oil holding tank sludge is classified as

hazardous waste. Depending on the tank size and rate of slurry

oil production, treatment and disposal cost estimates are

US$1 – 4 million per cleaning. In the absence of

countermeasures, increasing resid feed to the FCCU will

increase the rate of slurry oil production and sludge

formation.

6

Membrane filters were first put into slurry oil service

around 1990. Mechanical filtration operates at temperatures

up to 600°F and employs tubular porous metal elements.

The solids collect on the inside of the elements, while the

filtrate passes through to the outside. Some filters use

porous sintered woven wire mesh metal filters and operate

at 400 – 650°F, while others employ a 2 – 5

μm

woven wire

filter element, using light cycle oil (LCO) as a backwash at

350°F and claim 85 – 95% solids removal from the feed

slurry. Use of these filters in the area of slurry fines removal,

especially in the RFCC process, has become unreliable. In

many cases, elements are completely clogged by

asphaltenes and waxes, causing the unit to become

inoperable. Upon inspection, many elements show high

evidence of erosion during turnaround or unscheduled

maintenance. In the case of replacement, over

300 elements are affected and maintenance costs are

substantial.

6

Electrostatic precipitators are routinely used to remove

catalyst fines from the FCCU stack. An electrostatic

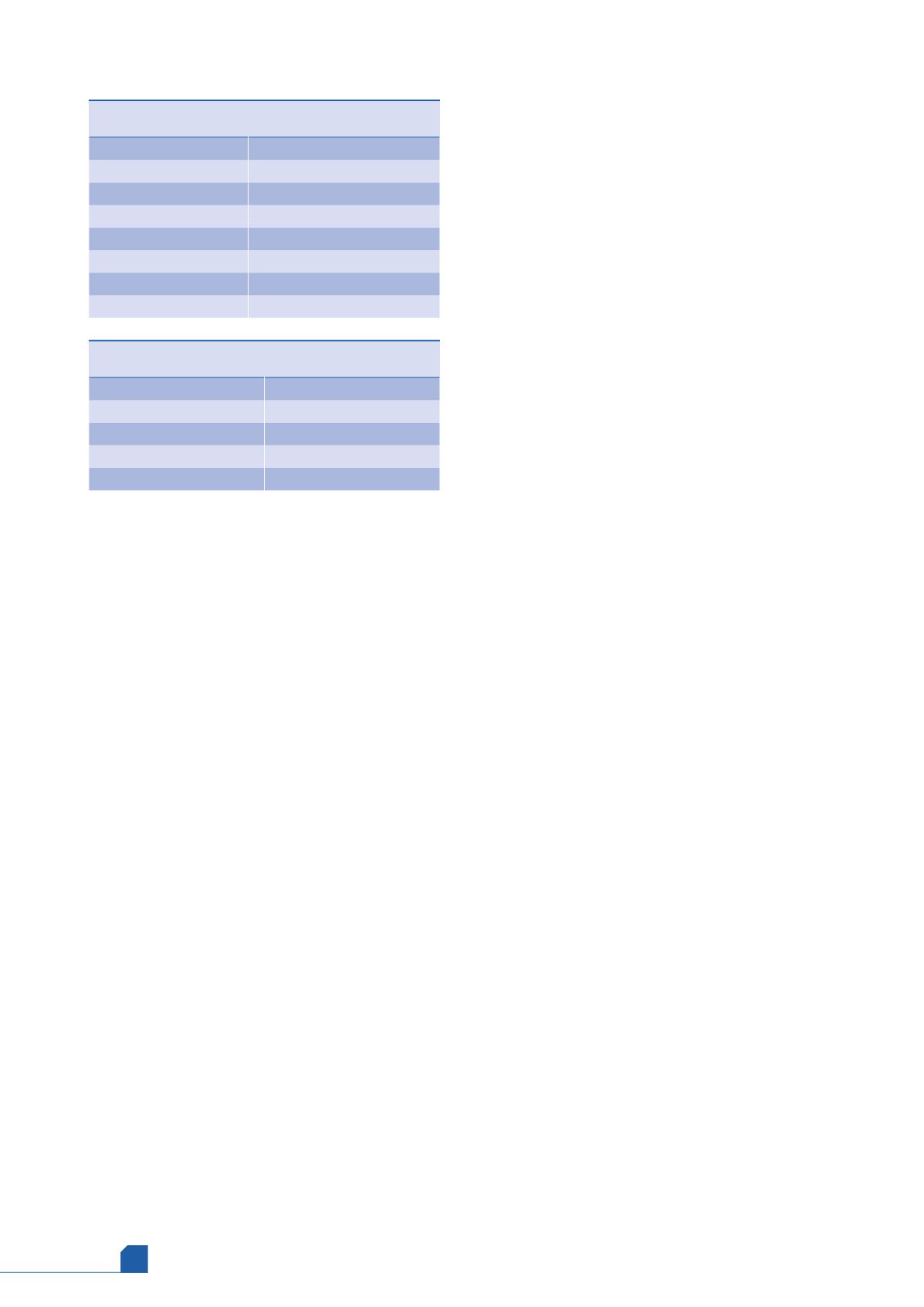

Table 1.

Typical slurry oil properties ranges from a

number of FCCs

8

Property

Range (minimum to maximum)

API gravity

-6 to + 8

Sulfur (wt%)

0.3 to 5.0

Nitrogen (wt%)

0.1 to 0.5

Nickel (ppmw)

0 to 110

Vanadium (ppmw)

5 – 200

Asphaltenes (vol.%)

0 to ~8

Solids (ppmw)

1000 – 6000

Table 2.

Particle size distribution ranges from a

variety of slurry oils

8

Particle dia.

% in range

0 – 5

30 – 60

5 – 15

30 – 55

15 – 25

2 – 12

25+

1 – 5