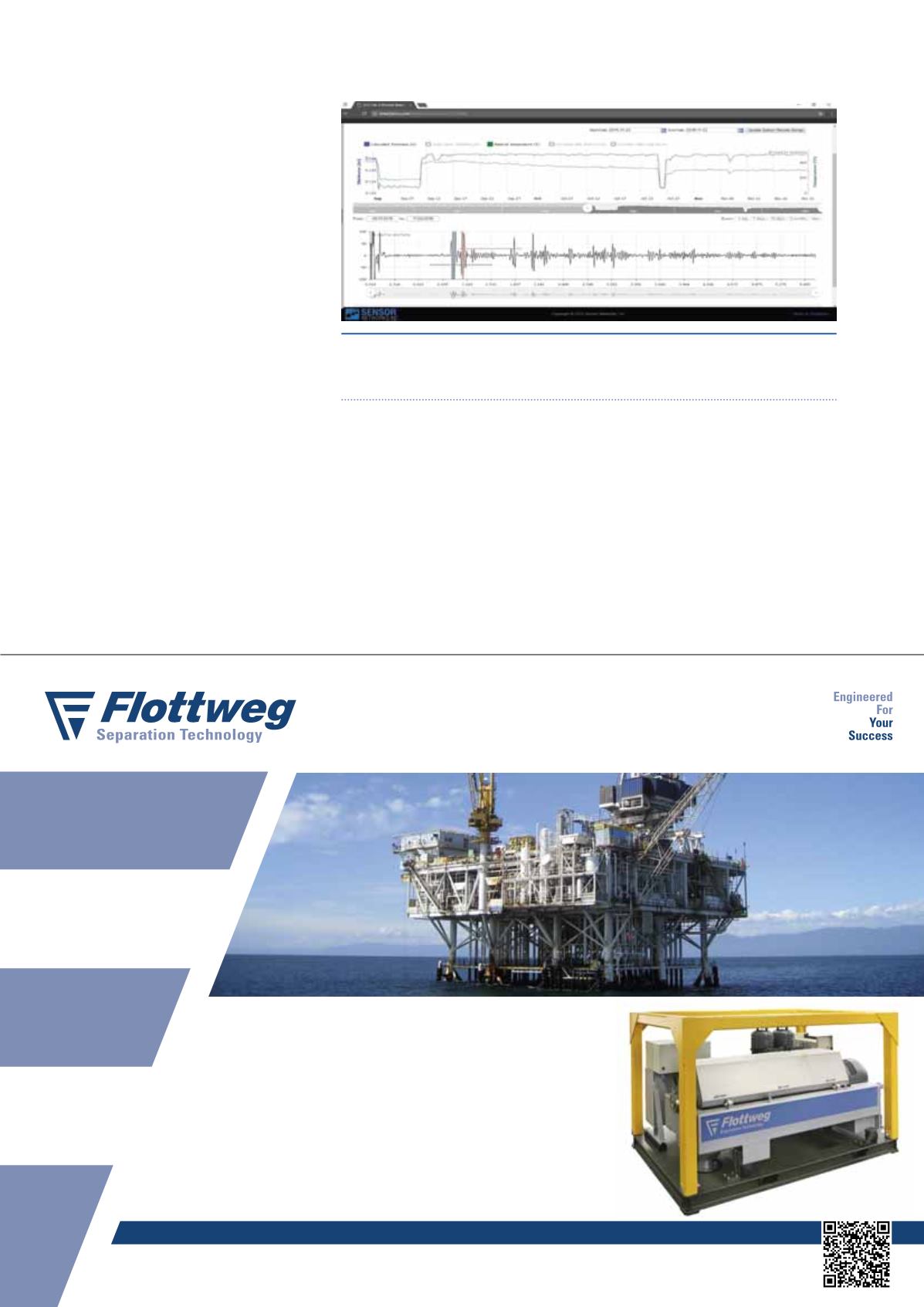

software can also store thickness

readings and has a web browser-based

user interface (Figure 3) that allows for

the display of data and asset integrity

information. The application can be

viewed through standard

browser-enabled devices such as

laptop computers, tablets and smart

phones.

Crude unit overhead

monitoring

Remote corrosion monitors were

placed on the overhead elbow of the

processing tower. During a recent

turnaround, the top of the tower had

been replaced and upgraded with a

Monel (UNS04400) liner due to corrosion. The overhead

condensers had a history of corrosion, requiring weld

buildup and equipment replacement, and the overhead line

had been replaced on at least one occasion. Remote

corrosion monitors were installed on known low spots on

the overhead elbow to provide insight on how operating

conditions affected corrosion activity. With this

knowledge, integrity operating windows (IOWs) could be

directly correlated to real time equipment damage. By

collecting accurate corrosion rates, the necessary

replacement date of the elbow could be predicted with

increased confidence. The remote system could also help

decrease the frequency of manual inspections for this

equipment. To put this in perspective, prior to replacing

the top of the tower, inspection crews had been climbing

the 130 ft (39.6 m) tower on a weekly basis in order to

manually collect UT thickness readings.

Remote corrosion monitoring was accomplished by

installing a cellular-based ultrasonic thickness monitoring

system, including eight dual element transducers. A

viscoelastic ultrasonic couplant and magnetic attachment

were used to mount and couple the transducers to the

piping. The viscoelastic couplant was chosen rather than a

rigid adhesive so that the transducers can be easily

Figure 3.

Web-based interface for installed sensor data shows both the raw

and trended data. Metal loss rates of 0.001 in. (0.025 mm) with a resolution

of 0.0001 in. (2.5 microns) is easily observable.

P L E A S E V I S I T U S AT O T C I N HOU S TON – U S A , G E RMA N PAV I L I ON , BOO T H 3 6 2 5

Flottweg SE • Industriestraße 6-8 • 84137 Vilsbiburg • Germany

Tel.: +49 8741 301-0 • Fax:

+49 8741 301-300

•

mail@flottweg.com•

www.flottweg.comFLOTTWEG DECANTER CENTRIFUGES

for Separation and Processing of

Drilling Muds, Fluids and Emulsions

Your advantages with Flottweg Machines:

•

Reduction in disposal costs

•

Reduction in the quantity of sludge in the closed system

•

Cost saving of up to 60% for maintenance and upkeep

•

Reduction in wear, especially on the slurry pump and drill bit

•

Extended sludge service life