March

2017

HYDROCARBON

ENGINEERING

74

removed and reattached for automated UT scanning

and/or redeployment to other monitoring locations in the

facility. The transducers were placed in positions where low

spots had been identified through manual UT. The system

was powered by batteries and needed no external

connections to either power or plant IT infrastructure. Data

was backhauled on a once per reading schedule to a

cloud-based data server, and a web browser application

was used to view and analyse the data.

Atmospheric gas oil circuit

Background

Opportunity crudes continue to present the refining

industry with concerns about naphthenic acid corrosion

(NAC) of carbon steel and chromium steels in service

temperatures greater than 425˚F (218˚C). The corrosion

rate of the metal is based on a number of factors such as

naphthenic acid species, sulfur content, velocity,

temperature, silicon and chromium content (within

specification range), wall shear stress, and solids content

of stream. NAC may occur at total acid numbers less than

0.5 mg KOH/g.

3

These variables may dramatically change

the corrosion rates in a matter of weeks. Installed sensor

thickness readings at these temperatures not only provide

continuous corrosion rates, but also eliminate the concern

for proper calibration, which can greatly affect the

validity of the readings. Installed sensors can account for

temperature changes automatically; inability to track such

changes has been a common source of error. When these

sensors are used in conjunction with a corrosion inhibitor

programme, real time adjustments can be made to

optimise chemical costs with increased mechanical

integrity.

A 3 in. Sch 40 atmospheric gas oil (AGO) circuit was

selected for monitoring due to high levels of NAC in the

circuit. The piping was already subject to greater than 50%

wall loss, and the process temperature had been decreased

in an attempt to mitigate the corrosion process. A

turnaround that would replace the subject pipework was

scheduled to occur within the next 12 months, but there

was a desire to validate the sufficient reduction of the

corrosion rate so that line operation could be continued in

confidence until the next planned turnaround.

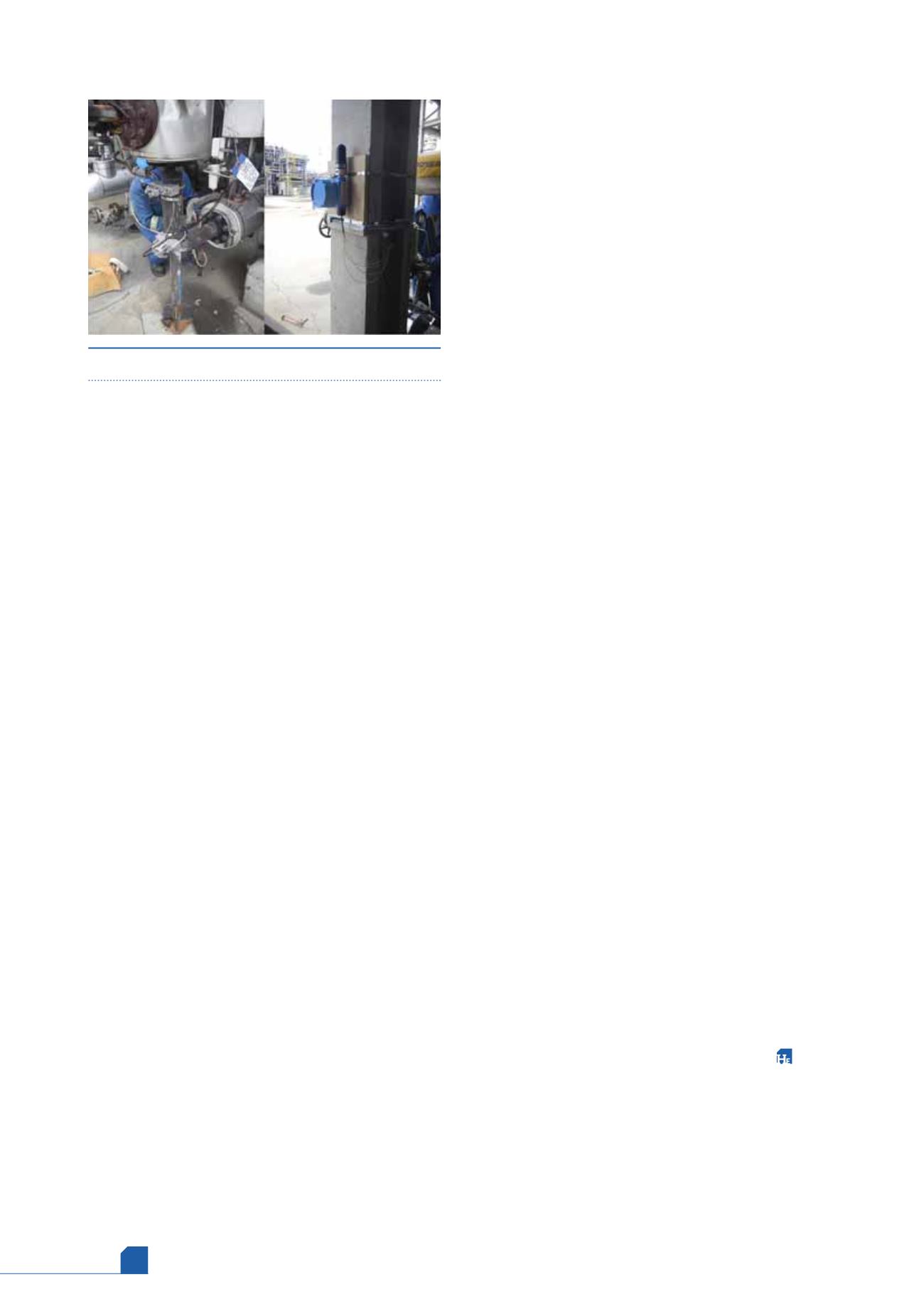

Figure 4 shows the installation of a cellular-based

ultrasonic monitoring system, including four high

temperature transducers and a resistance temperature

detector (RTD). The transducers are clamped using

brackets and U-bolts as an alternative to welding brackets

to the pipework, which would be problematic on this line

due to its remaining wall thickness. The high temperature

solution utilises a metal-to-metal coupling with a thin

gold foil acoustic couplant layer between the probe and

pipework. This type of solution is necessary for pipe

circuits operating at temperatures greater than

approximately 392˚F (200˚C), as organic adhesives or

other traditional ultrasonic coupling methods are

unreliable. Process temperatures for the subject pipework

were measured to be 662 – 752˚F (350 – 400˚C). The

system was powered by batteries and required no external

connections to either power or plant IT infrastructure.

Data was backhauled on a four hour reading schedule to a

cloud-based data server, and a web browser application

was used to view and analyse the data.

Temperature monitoring was included to compensate

for UT thickness reading variations due to temperature, as

temperature is one of the largest noise factors in installed

ultrasonic sensor data. The variation of ultrasonic velocity

as a function of temperature is estimated to be

approximately -1% per 100˚F (55˚C). Consequently, as

temperature rises, any ultrasonic thickness gauge will

measure an increase in time of flight and a corresponding

increase in thickness if the ultrasonic velocity is not

temperature corrected. For example, if a calibration is

performed on a room temperature calibration block at

70˚F (21˚C), and then, subsequently, a measurement is

performed on the same block at 970˚F (521˚C) without

adjusting the velocity, the thickness will be overestimated

by approximately 9% due to the shift in material velocity.

Conclusion

Opportunity crudes will continue to be available in

different markets at reduced costs to the refiner with

certain enhanced corrosion concerns. With the recent

developments in low cost, low power, solid state

electronics combined with lithium-ion batteries and

ubiquitous cellular Internet of Things (IoT) connectivity,

4

refiners can accurately determine real time corrosion rates

and implement a corrosion control programme to mitigate

risks associated with opportunity crudes using these new

and unique solutions. These methods, while employing

industry accepted measurement techniques, are now able

to provide reliable, accurate, high resolution wall thickness

data at very frequent measurement intervals, and are

therefore valuable to plant maintenance and corrosion

engineering departments at cost effective prices.

References

1. NUGENT, M. J. and BABAIAN-KIBALA, E., 'Naphthenic Acid Corrosion

Literature Survey', NACE Corrosion/99, Paper No. 378, (April 1999).

2. SNI 2016 NACE Paper.

3. NUGENT, M. J. and DOBIS, J. D., 'Experience with Naphthenic Acid

Corrosion in Low Tan Crudes', NACE Corrosion/98, Paper No. 577,

(March 1998).

4. Sensor Networks, Inc. USPTO Patent Applications #2016/0109411

and 2016/0274065-A1.

Figure 4.

AGO monitoring installation.