March

2017

HYDROCARBON

ENGINEERING

78

achieved faster resolution of the oil/water emulsion in

the desalter and significantly improved the brine quality,

eliminating its negative impacts on the wastewater

treatment plant.

Solving the brine quality issues allowed the refiner to

improve its crude diet flexibility and increase the

percentage of this heavy opportunity crude in its crude

slate, unlocking US$120 000/d in additional profit.

Case study 3

A refiner along the US Gulf Coast was experiencing

desalter reliability issues when processing high calcium,

high TAN South American crudes (Figure 2). The high

conductivity of these crudes

compromised the effectiveness of

the desalter’s electrical grids,

increasing the amperage draw and

reducing the voltage differential

between the grids.

As a result, the driving force

behind water and oil separation was

lost. This led to a subsequent

decrease in brine quality, which

raised the risk of upsetting the

downstream waste treatment

facilities. It also resulted in an

increase in desalted crude basic

sediment and water (BS&W) to as

much as 1.4%, which increased the

risk of downstream fouling and

corrosion.

The refiner required a processing

solution that would allow it to

process a higher volume of calcium

naphthenate crudes without

compromising desalter reliability.

Baker Hughes conducted a

system-wide survey to determine the

root cause of the problems. Based on

the findings, the service provider

recommended its contaminant

removal additive for calcium removal

and emulsion control when

processing these South American

crudes.

With the new technology applied,

the conductivity of the calcium

naphthenate crude was reduced and

the desalter amps were stabilised.

Once the desalter operation was

under control, the refiner could

process an additional 13 000 bpd of

calcium naphthenate crudes without

any drop in asset reliability or

performance. This increased

processing volume translated to a

profit gain of US$50 000/d (Figure 3).

Technology for the

future

Today's refiners face increasing market pressures,

compressed crude differentials, rising crude prices, and

product supply gluts. These drivers will only grow in the

future, compelling refiners to process higher volumes of

opportunity crudes and continue pushing refinery units far

beyond their design limits. A dynamic and flexible

contaminant removal programme offers a comprehensive

treatment solution – one tailored to solve today's

processing problems and be easily reconfigured to meet

future refinery targets and cost objectives.

Note

EXCALIBUR is a trademark of Baker Hughes Inc.

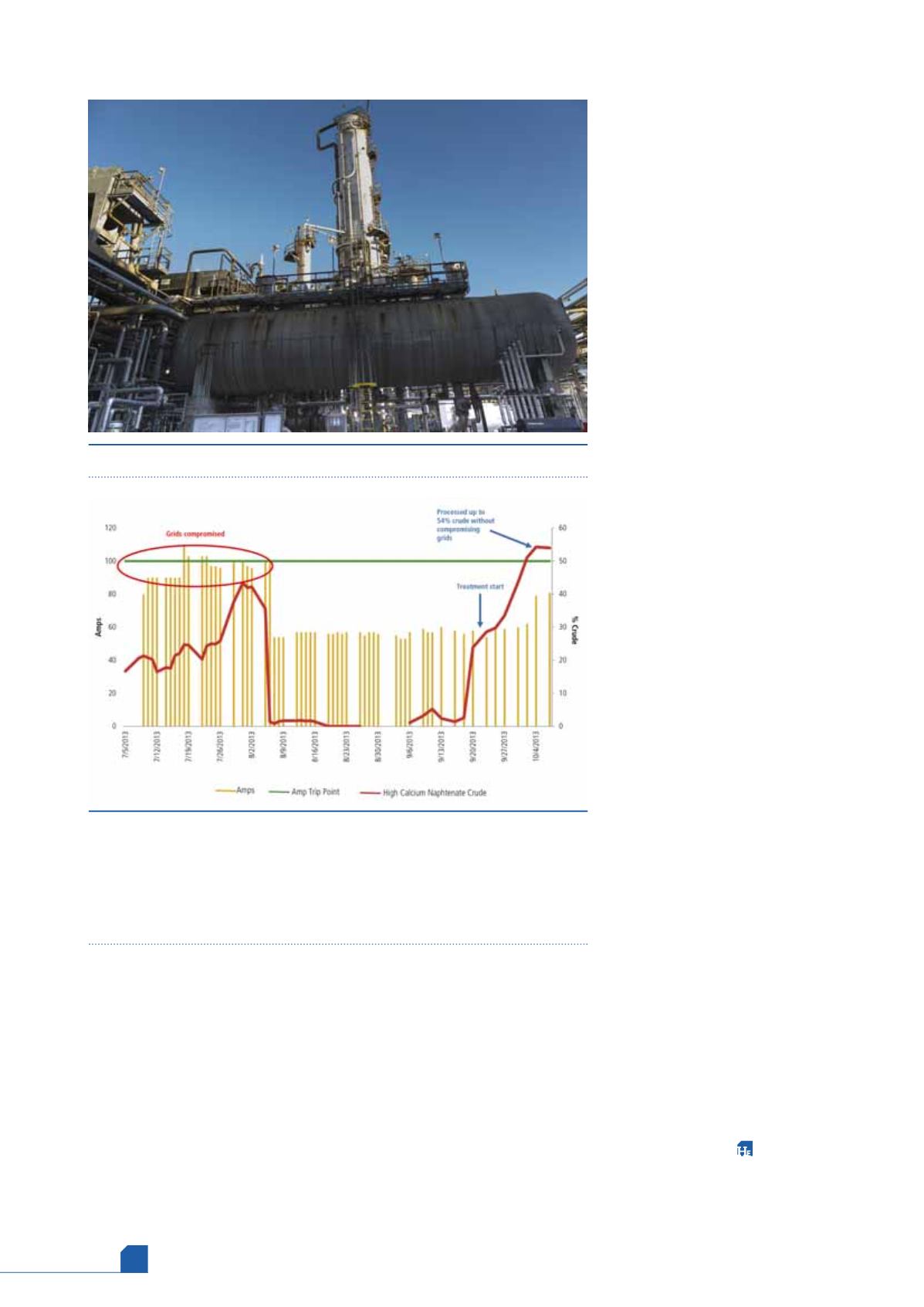

Figure 3.

Grid amperage as a function of the percentage of high calcium

naphthenate crude sent to the desalter. Prior to the EXCALIBUR treatment,

large concentrations of high calcium naphthenate crude resulted in a

significant increase in amperage, past the grid’s amp trip setting. The refiner

stopped processing this crude to maintain the amperage at reasonable

levels. After starting the programme, the refiner was able to process a crude

slate with 54% of this crude without compromising the grids.

Figure 2.

Desalter and crude tower at a US refinery.