March

2017

HYDROCARBON

ENGINEERING

72

a direct actual wall thickness measurement, and are

installed, maintainable and replaced without hot work or

intrusion into the process stream.

Once monitoring is capable of collecting accurate

corrosion rates, the owner-user has the ability to decide

(based on short or long-term economics) whether to limit

the amounts of opportunity crudes, apply targeted

corrosion inhibitors or metallurgical upgrades, or utilise a

combination of everything. For all of these options,

accurate assessment of the impact of these crudes in the

specific locations is the keystone to success.

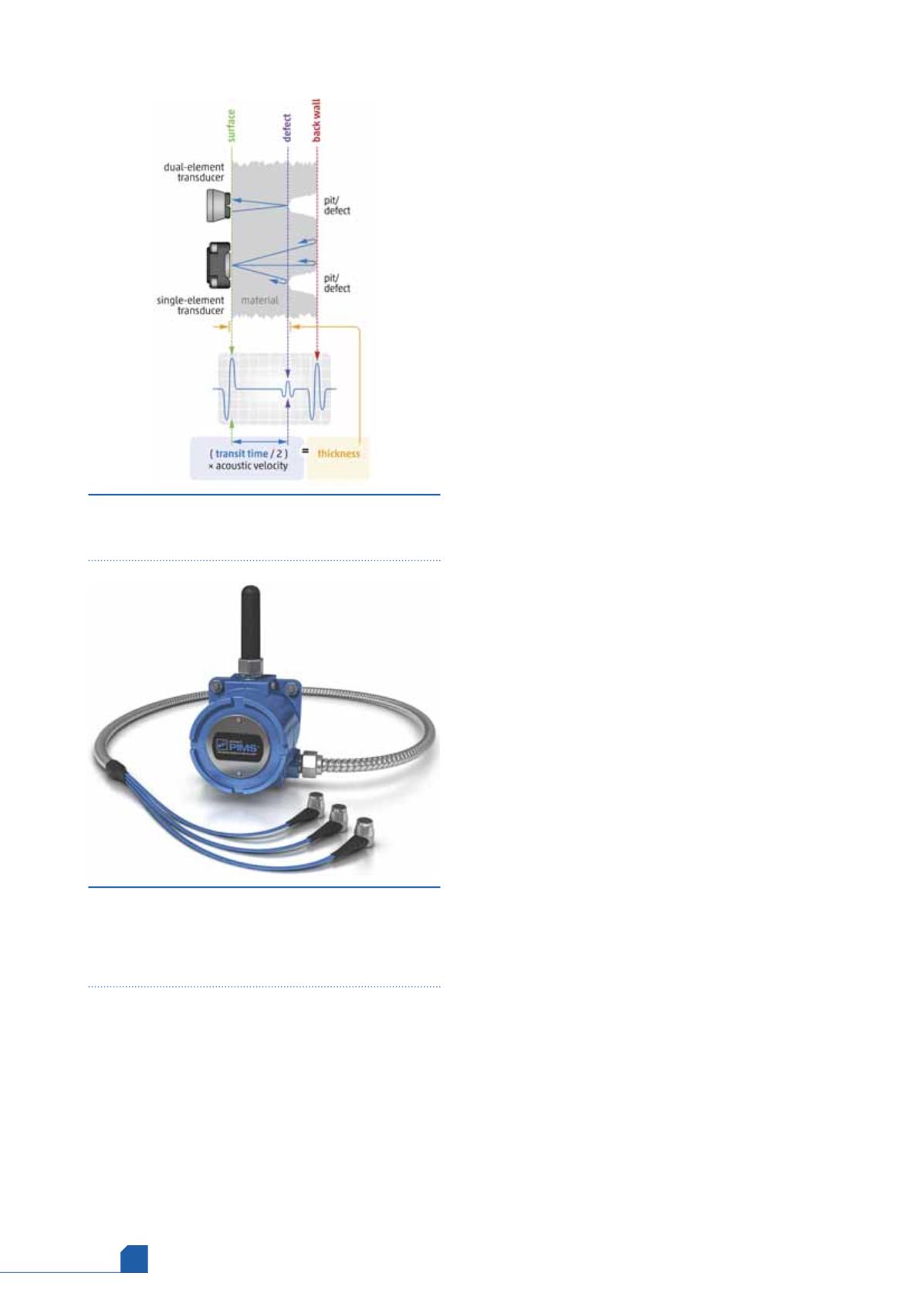

Permanently installed ultrasonic

sensors

Similar to industry proven and accepted manual thickness

gauging, permanently installed UT sensors use ultrasonic

transit time to measure the wall thickness of a part

(Figure 1). However, the technique is fundamentally

different from manual thickness gauging in that the

transducers and their instrumentation are deployed

permanently or semi-permanently with automatic data

acquisition. This function addresses several of the

shortcomings of existing manually deployed solutions.

Some of the major advantages are:

Instrumentation and probes are deployed on the asset

in a permanent or semi-permanent fashion and can be

accessed remotely, reducing the cost of access over

time and eliminating the need to deploy operators to

the point of inspection. Once the instrumentation is

deployed, data can be acquired remotely via a web

portal/the internet.

Due to the fixed positions of the transducer and

instrumentation, operator-to-operator, probe-to-probe,

and instrument-to-instrument variability is eliminated.

This fixity removes significant sources of error and

allows for improved measurement resolution, precision,

and accuracy, which are particularly important for

accurate short-term, corrosion rate trending;

subsequently, asset management can be nearly real

time.

Data can be collected on a more frequent basis (more

than once a day) for automated systems. Greater data

collection frequency allows for more accurate

corrosion rate trending through statistical data analysis,

such as linear least squares regression. This technology

also has the ability to capture episodic corrosion

events caused by equipment upsets or unusual

startup/shutdown situations.

The system can be deployed with an integrated

temperature measurement device so that changes in

material acoustic velocity, due to temperature

variations, can be automatically compensated in the

measurement, thus eliminating another significant

source of measurement error.

The data is easily accessible. Wireless installed sensor

systems can use various forms of data recording,

including the plant’s wired or wireless intranet,

industrial wireless networks such as 802.15.4 (wireless

HART, ISA100 or ZigBee), and satellite or cellular

networks for remote collection points. These options

provide near real time data/asset health availability.

Another recent development is the use of cellular

radios for data acquisition and transmission. Because the

instrument is capable of connecting to and using available,

third party cellular networks, it avoids the problems and

high costs associated with mesh network, gateways and

plant IT infrastructure. This allows the deployment of even

single inspection points at low cost, without the expense

of gateway installation or IT personnel evaluation. The

instrument (Figure 2) is connected via an available cellular

network to a cloud server that runs application software

designed to communicate with the instrument, which

collects ultrasonic and/or other data associated with the

integrity of the asset being monitored. The application

Figure 1.

The ultrasonic principle for thickness

measurement, shown with single or dual element

transducers.

Figure 2.

Installed UT sensor system shown with

three dual element transducers, temperature sensors

and cellular connectivity. This battery powered

device can support up to 16 transducers and run for

5 to 7 years.