March

2017

HYDROCARBON

ENGINEERING

44

Fluid catalytic cracking pre-treat

The pre-treatment of feed for fluid catalytic cracking (FCC) units

offers significant performance advantages for FCC operation

including overall increase in conversion, improved yield

selectivity, FCC products that meet clean fuels specifications,

and reduced catalyst usage. Many refiners have leveraged the

advantages offered by fluid catalytic cracking pre-treat (FCCPT)

units to increase profitability and flexibility. In light of the critical

role that this technology plays in modern refining, Criterion has

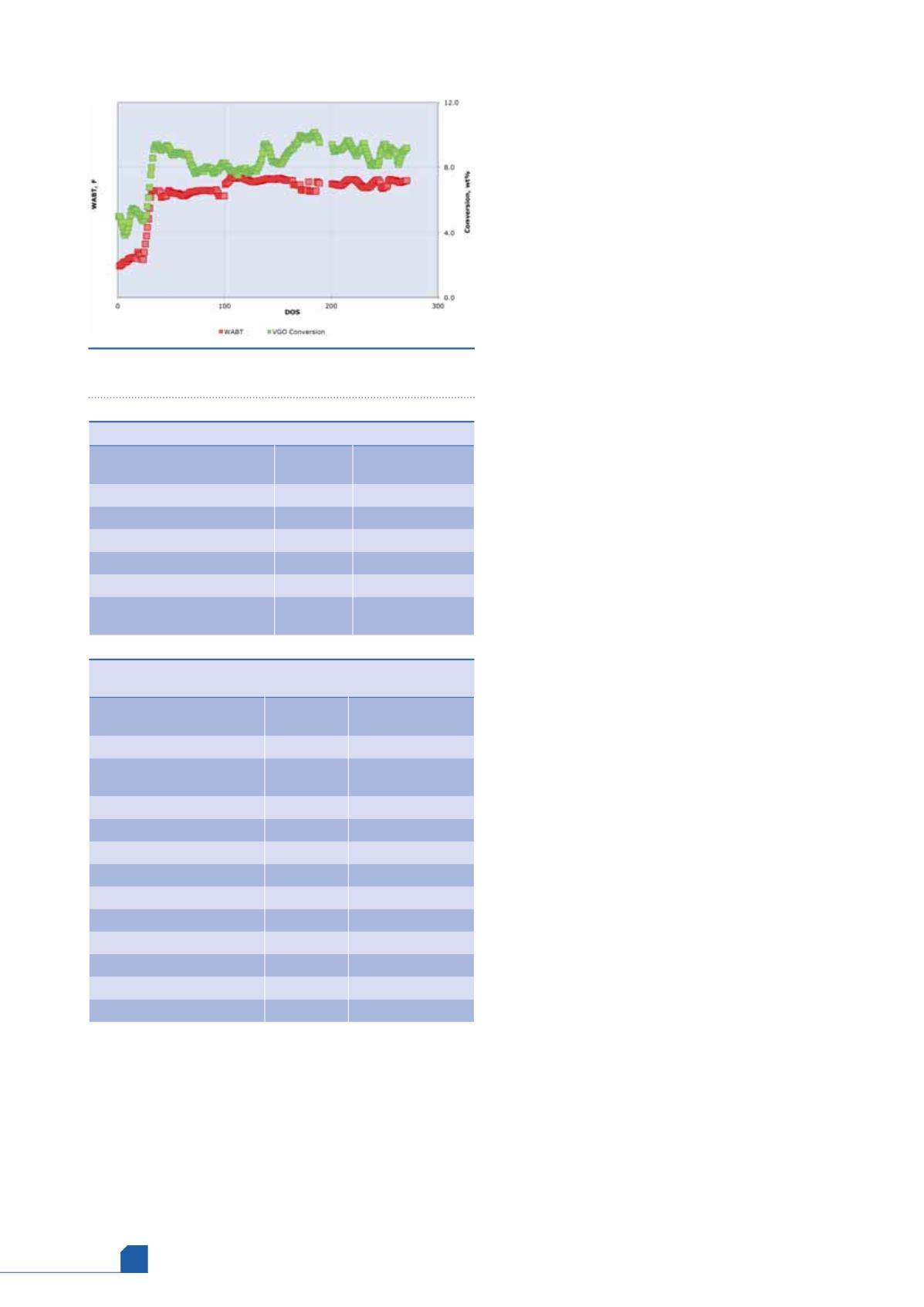

Figure 3.

Impact of FCCPT severity on vacuum gasoil (VGO)

conversion.

Table 3.

CENTERA FCCPT performance in Tier 3 mode

FCCPT performance

Typical

Criterion

Tier 3 mode

Operating mode

HDS

Arosat

TLP volume gain (LV% of feed)

Base

+ 1.25

Product sulfur (ppmw)

1000

300

Product nitrogen (ppmw)

500

100

API gain (°)

Base

+ 1.2

Distillate conversion (wt% of

feed)

Base

+ 4.1

Table 4.

Impact of improved FCCPT performance on

FCC

FCC

Typical

Criterion Tier 3

mode

Combined feed sulfur (ppmw)

1200

570

Combined feed nitrogen

(ppmw)

360

160

Combined feed API (°)

Base

+ 0.7

Riser top (°F)

Base

- 20

Conversion (%)

Base

+ 0.5

Gasoline sulfur (ppmw)

46

10

Gasoline octane (R+M/2)

Base

Base

Dry gas (wt% of feed)

Base

- 0.51

TLP volume gain (LV% of feed) Base

3.9

Gasoline (LV% of feed)

Base

+ 3.66

LCO (LV% of feed)

Base

+ 0.27

Slurry make (LV% of feed)

Base

- 0.35

continued to develop and apply new advanced

catalysts and solutions for FCCPT applications.

CENTERA catalysts have demonstrated excellent

hydrogenation performance, as well as effective HDS

and HDN activity. A key feature of these products is

their synergistic behaviour when applied in stacked

systems.

The saturation of aromatics enables improved

product upgrade for increased FCC yields while also

increasing the rate of deep desulfurisation via direct

desulfurisation routes. In addition, the high

hydrogenation activity enables increased HDN, both

improving FCC feed quality as well as improving

hydrotreater performance as nitrogen inhibits the HDS

reaction. The hydrogenation of FCC feed streams is

necessary for deep desulfurisation especially when

operating at a higher HDS target for Tier 3 FCC gasoline

production. As such, many refiners have included the

application of high severity FCCPT operation in their

strategies for Tier 3 fuels production since FCC gasoline

is a major blend component of the mogas pool. As

discussed previously, the synergy offered by the

strategic application of NiMo and CoMo catalysts

greatly improves the hydrogenation horsepower of the

overall catalyst system. This is in contrast to the

performance of single catalyst systems, which require

the promotion from Ni on a CoMo catalyst to perform

enhanced HDS.

Example one

The following commercial example illustrates the

performance achieved by a refiner operating an FCCPT

unit to produce a Tier 3 quality gasoline blend

component, increasing conversion in the FCCPT unit as

well as conversion and yields on the FCC unit. This unit

is currently operating with CENTERA technology in a

stacked catalyst system at targeted operating

conditions for maximum performance. Figure 3, Table 3

and Table 4 highlight the performance benefits achieved

post application of Criterion’s technology compared to

a typical catalyst system. The technology has resulted

in an increase in FCCPT conversion and FCC

performance with improved yields, while the catalyst

system remains on target to provide an extended life

cycle.

Example two

The run length (Figure 4) of this high pressure FCCPT

unit was increased from 18 to 36 months by

implementing a stacked system using CENTERA NiMo

DN-3651 and CoMo DC-2650 and an improved

OptiTrap

TM

grading design. These two improvements

resolved both activity loss and chronic delta P (dP)

growth in the unit. The catalyst system delivered better

than expected improvements in activity; SOR

temperature was on target and stability was also

improved. In beds one and two, which needed to be

skimmed halfway through the cycle, dP increased

rapidly. A number of changes were made to the grading

scheme in the top beds (loading filter tray cartridges