March

2017

HYDROCARBON

ENGINEERING

39

pumps, compressors, exchangers, valves, and turbines.

Combined with an interface to process design simulation

software, this solution helps users rapidly deploy

equipment or process monitoring on any plant asset –

eliminating the need for complex model development.

It is important to remember that the IIoT is not just

about capturing sensor data. Information needs to be put

into the asset context structure; merely operating on

tag-based data will not ensure a repeatable and scalable

solution. Processes are instrumented for control rather than

reliability or optimisation. As a result, much of the ‘derived

data’ important for prediction and decision-making is

locked in spreadsheets and other standalone tools. It is

essential to continuously calculate this data and bring it

into the IIoT environment, where continuous runtime

analytics can examine historical performance for use in

machine learning algorithms.

Furthermore, IIoT solutions should not solely rely on a

statistical model to detect deviations from the norm.

Having a fundamental, physics-based model creates a

digital twin, with a virtual representation of the process or

asset located in the cloud. This allows users to model and

compare expected process performance against actual

results, and then apply these deviations as early indicators

of health degradation.

Digital twins exist at the intersection of physical

engineering and data science, and their value translates

directly to measurable business outcomes: reduced asset

downtime, lower maintenance costs, improved plant and

factory efficiency, reduced cycle times, and increased

productivity.

Benefits to industrial organisations

Rapid adoption of the IIoT has created economies of scale

for smart sensors, connectivity, analytics, and robust

software platforms. This change is driving the adoption of

enterprise-level performance management, process

monitoring, predictive maintenance programmes, and

business transformation with the goal of eliminating

unplanned downtime and reducing operating costs while

maintaining product quality and compliance.

A real world approach to the IIoT enables the

integration of current systems and the addition of new data

sources and analytics to support complementary,

continuous improvement processes, focused on

performance monitoring and decision support. The specific

benefits of this approach include the following:

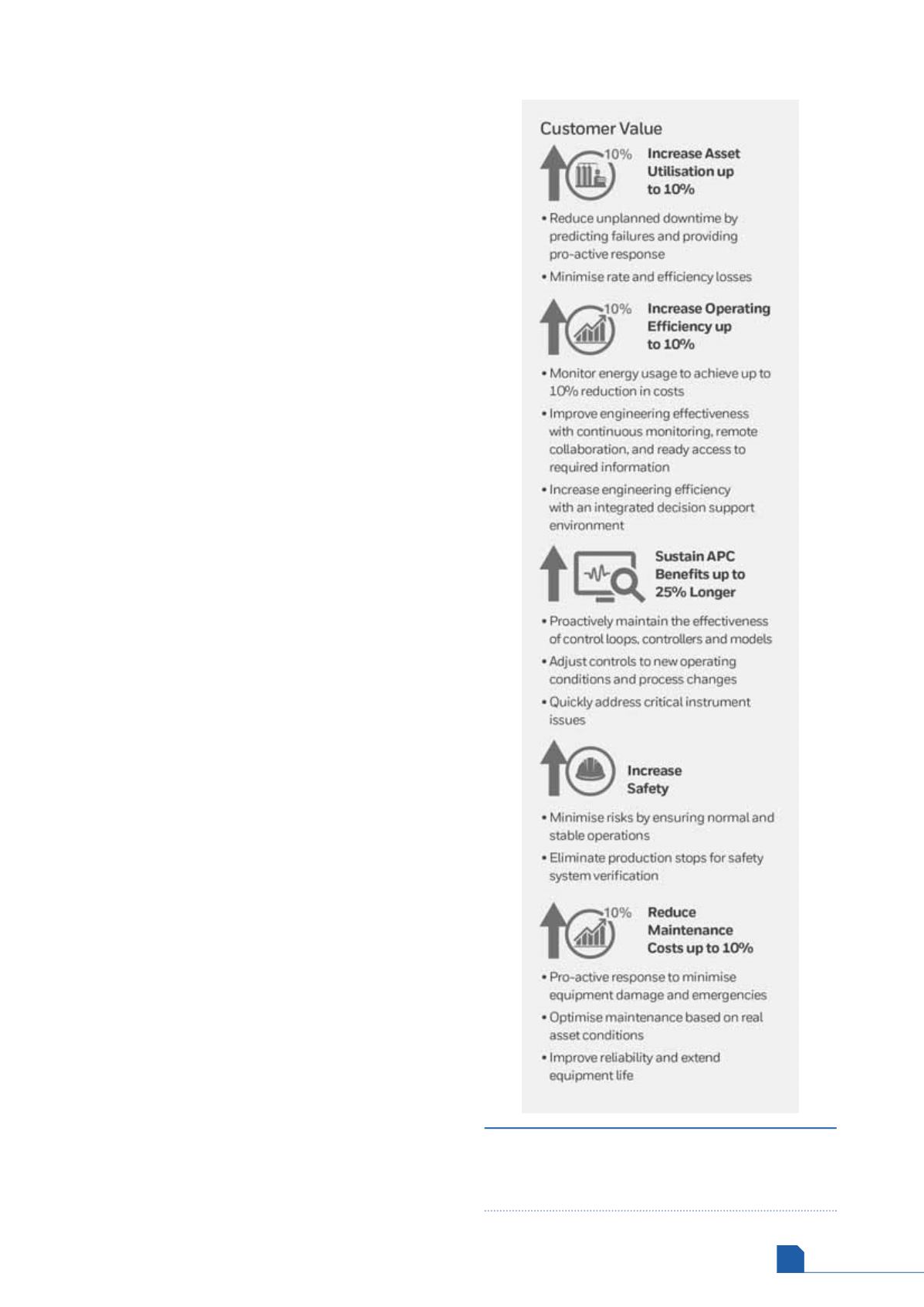

Increase process reliability and asset utilisation up to

10%: plants can reduce unplanned downtime by

defining and operating within operating and integrity

envelopes, predicting failures and providing proactive

responses, as well as minimising rate and efficiency

losses.

Increase operating efficiency up to 10%: industrial

organisations can manage performance, including

yields, energy and raw material usage, to achieve up to

10% reduction in costs. This results from enhanced

engineering and production effectiveness with

continuous monitoring, remote collaboration and ready

access to required information, as well as improved

decision support.

Figure 3.

There are measurable benefits from the

integration of current systems with new data sources

and analytics that complement processes focused on

performance monitoring and decision support.