March

2017

HYDROCARBON

ENGINEERING

46

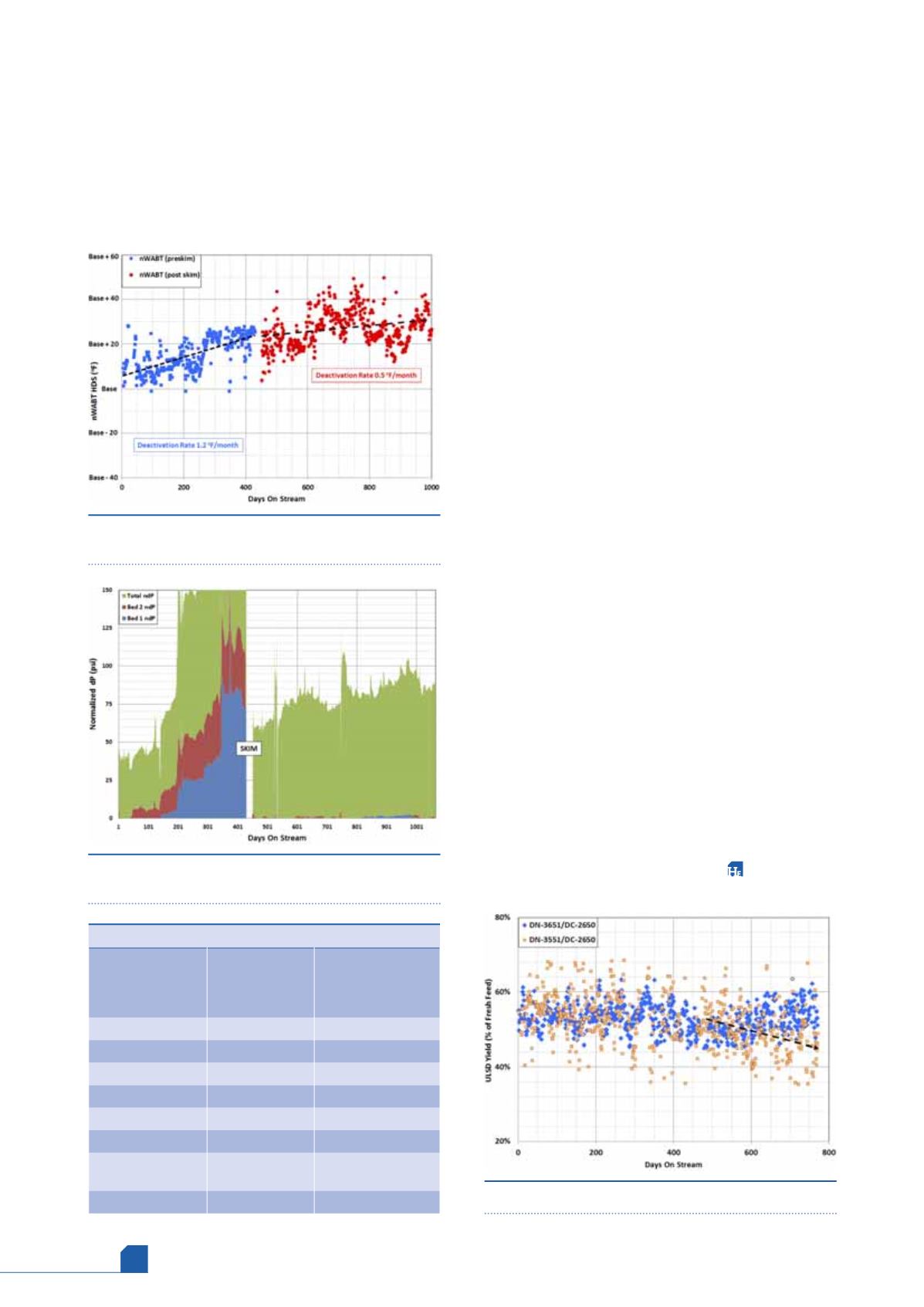

with smaller size grading, increasing grading depth and

adding additional size layers), which have greatly reduced

the rate of dP increase (Figure 5).

Example three

Another FCCPT unit that processes 100% cracked stock had

an improved diesel yield after switching to a NiMo/CoMo

stack of CENTERA DN-3651 and DC-2650. This unit has

historically experienced a steady decline of ULSD yield in

the last 6 – 12 months of the cycle. The higher activity and

stability of the system enabled a 10˚F increase in diesel T95,

while also providing higher H

2

consumption and thus

increased volume swell. In addition, the diesel yield was

maintained above 50% for the entire cycle (Table 5). The

combination of higher feed rate and increased diesel yield

had a significant impact on refinery distillate production

and margin. The enhanced stability of the catalyst meant

that the unit was able to process more difficult feed (higher

nitrogen, increased LCO, lower API) while maintaining yield

stability throughout the cycle (Figure 6).

In addition to FCC feed quality, use of stacked catalyst

systems also improves unit stability and cycle longevity. The

application of high performance catalysts offers expanded

catalyst life cycles by reducing operating temperatures

required to meet product specifications at the start of run as

well as reducing the rate of deactivation as the cycle

progresses. In general, hydroprocessing catalysts suffer from

deactivation due to two primary mechanisms; poisoning of

active sites due to feed contaminants such as metals, and

the formation of coke on the surface of the catalyst

inhibiting access to the active sites. Criterion’s FCCPT

portfolio includes performance guard products to protect

from poisons, as well as substrate geometry and pore

structure to enable high tolerance to feed poisons

permitting maximum available active volume.

Conclusion

Customised stacking solutions are bringing refiners

additional value globally. These catalyst technologies,

combined with stacking solutions, results in long-term

catalyst system stability. The application of specific catalyst

layers throughout the reactor permits the use of the ideal

catalyst in targeted temperature zones, which not only

unlocks additional performance but reduces the

deactivation potential of each of these regions that are

susceptible to aromatics equilibrium limitations and the

formation of coke. This is the synergistic advantage of

adding non-capital intense solutions to create added value

with what a refinery already has in place.

Figure 6.

ULSD yield stability improvement.

Figure 4.

High stability with CENTERA stack of

DN-3651 and DC-2650.

Figure 5.

Step change in dP growth before and after

skim.

Table 5.

Comparison of feed conditions

ASCENT

DN-3551/

CENTERA

DC-2650

CENTERA

DN-3651/ DC-2650

Feed rate

Base

+ 4%

LCO rate

Base

+ 37%

Feed API

Base

- 1.0

Feed sulfur

Base

Base

Feed nitrogen

Base

+ 9%

H

2

consumption

Base

+ 11%

Diesel yield, LV%

of feed

47%

52%

Diesel T95

Base

+ 10 ˚F