March

2017

HYDROCARBON

ENGINEERING

48

effective and flexible strategy for rapidly changing the

catalytic properties in the circulating inventory.

Maximising gasoline requires a high level of rare earth

exchanged ultrastablised Y-zeolite (RE-USY) in the FCC

catalyst. The RE-USY zeolite has a micropore structure,

into which the largest molecules that can enter are in the

middle distillate boiling range (carbon number up to

approximately C

20

, boiling range up to about

350°C/660°F). These are then cracked to smaller

molecules in the gasoline (C

5

– 221°C/430°F) and LPG

(C

3

+ C

4

) range. To switch from an optimised distillate

mode to an optimised gasoline mode requires the

catalyst RE-USY content of the inventory to be increased.

This can be achieved by changing the catalyst

composition, or more rapidly by using a catalytic additive

(e.g. Hi-Y) with very high RE-USY content to increase the

zeolite to matrix ratio of the circulating inventory.

Distillate mode is somewhat the opposite to

gasoline mode; lower severity operation is required that

leads to increased heavy cycle oil (HCO) and bottoms

make. Additionally, as described above, RE-USY will

convert the desired middle distillate product to

gasoline, so catalyst reformulation is required to

address these two issues. The RE-USY zeolite content of

the circulating inventory should be decreased to avoid

excessive cracking of the desired middle distillate

product. HCO and bottoms are large molecules with

boiling range >350°C/660°F and their conversion is best

achieved using mesoporous alumina (matrix). So, an

optimum catalyst will have a low zeolite and high

matrix alumina content, often characterised in terms of

low zeolite to matrix surface area ratio (i.e. low Z/M).

Once again, catalyst change-out will take several

months, resulting in missed opportunity. A more flexible

and rapid response is to back off catalyst make-up rate,

thereby decreasing replacement of fresh RE-USY, and

use a catalytic bottoms cracking additive (e.g. BCA-105)

with high matrix surface area. Importantly, the BCA

should not contain RE-USY because this would have the

unwanted effect of cracking desired distillate product

to gasoline and LPG.

Light olefins are valuable either as petrochemical

feedstocks (e.g. propylene) or for upgrading into high

octane gasoline blending components (e.g. alkylates and

ethers). To maximise light olefins it is necessary to

operate the FCC at high severity to maximise

conversion. The catalyst needs to be reformulated to

ensure heavy feed molecules are cracked through the

distillate and gasoline boiling ranges all the way to

propylene and butylenes. To do this, a careful balance

of matrix and zeolite contributions is required,

depending on the feed properties (lighter vacuum gas

oil [VGO] feeds requiring higher zeolite content, while

heavier residue feeds require higher matrix content).

Furthermore, for maximum light olefin selectivity,

excessive hydrogen transfer reactions should be

avoided, so excessive amounts of RE-USY should be

avoided, and ideally the RE content of the RE-USY

should also be decreased. However, light olefin

maximisation is best achieved using ZSM-5, a zeolite

with smaller micropores than those in RE-USY. Additives

containing zeolite ZSM-5 have unparalleled

performance for boosting light olefin selectivity in the

FCC. ZSM-5 zeolite acts as a molecular sieve, selectively

admitting gasoline range molecules into the ZSM-5

microstructure where they are cracked to propylene

and mixed butylenes. Some gasoline yield is lost in the

production of LPG olefins, but the octane of the

remaining gasoline is improved.

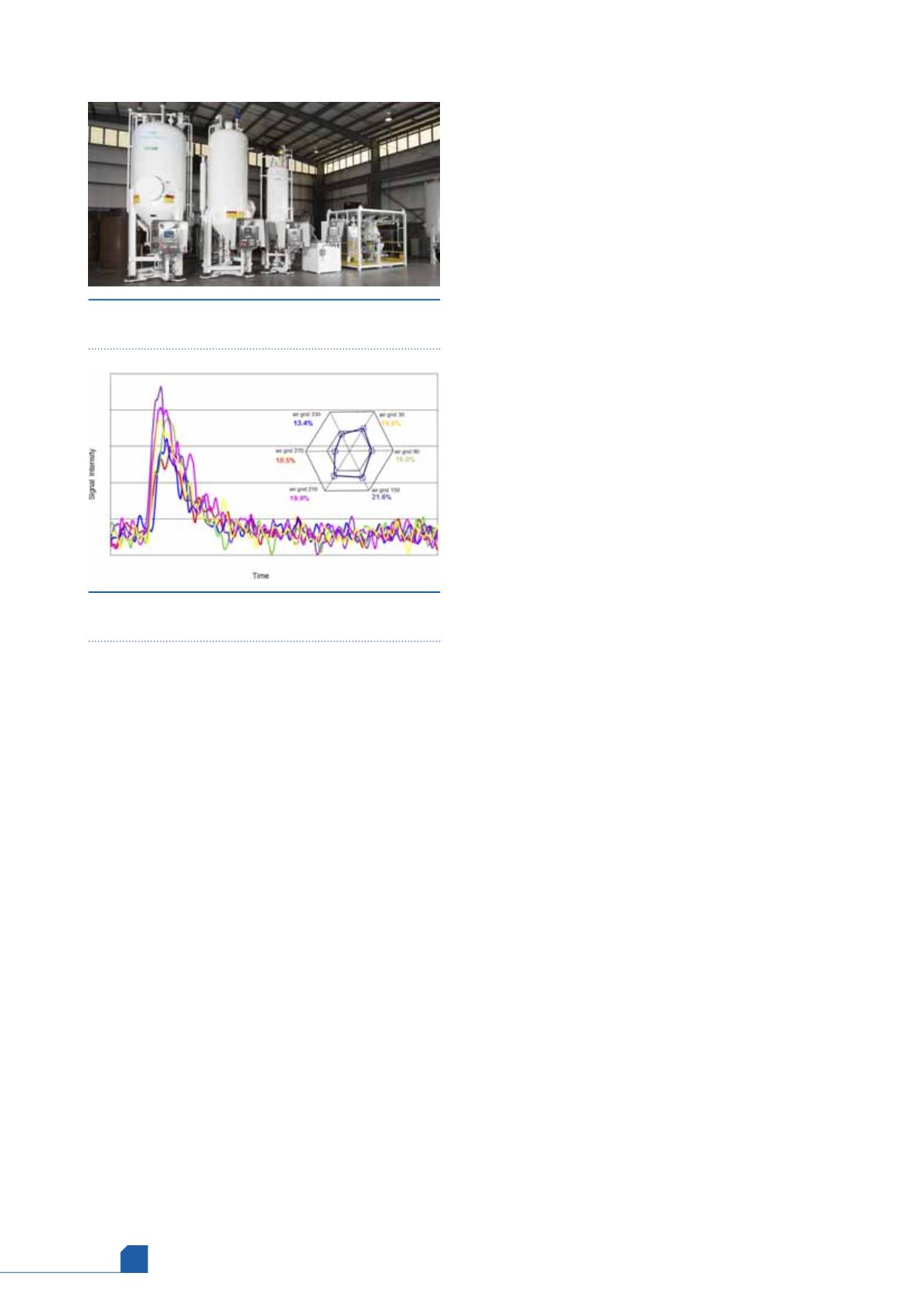

While additives can enhance the flexibility of FCC

operation between cycles of catalyst inventory,

dedicated additive injection systems enable a high

degree of operating flexibility to the refiner by

accurately and reliably allowing these various additives

to be used when required. These additive injection

systems (Figure 1) offer the operator flexibility to

introduce whatever dosage is necessary to meet the

optimum economic case, as well as the performance

requirements in that catalyst inventory cycle.

Sometimes there are changes in unit efficiency

where there is no clear indication of the cause. That is

when additional tools are needed to gather more

information about the unit performance. Radioisotope

technology is a powerful tool that plant personnel can

use to gain greater understanding of their FCC. Figure 2

is one example of this, where the FCC regenerator is

monitored using radioisotope technology to potentially

help operations optimise unit production or determine

if mechanical failure is the root cause of the air

maldistribution.

Figure 1.

Johnson Matthey's INTERCAT

JM

additive and

catalyst injection systems.

Figure 2.

Online diagnostics detecting FCC

combustion air distribution.