March

2017

HYDROCARBON

ENGINEERING

42

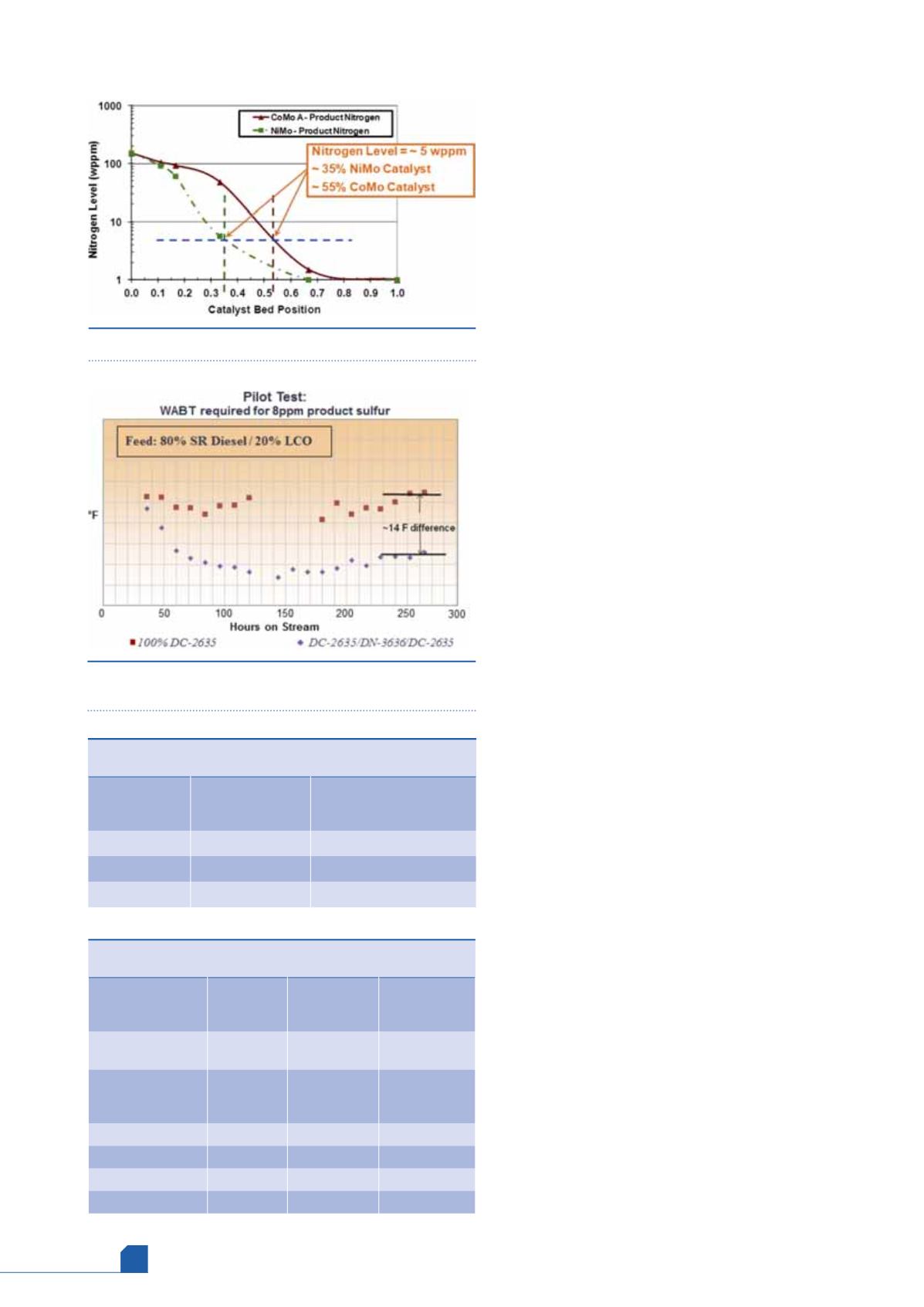

The HDS reactions in this section of the reactor are

relatively catalyst independent. In the upper and

mid-section of the reactor, it is critical to lower the

nitrogen level and saturate PNAs ‘unlocking’ the

performance of the balance of the catalyst system.

Figure 1 shows that nitrogen is effectively reduced

sooner in the catalyst bed with a NiMo catalyst

compared to a CoMo catalyst. This level of nitrogen

still effectively inhibits aromatics saturation (and

hydrogen consumption), but allows direct

desulfurisation reactions to occur more effectively in

the lower section of the reactor. The arrangement of

NiMo and CoMo catalysts is highly dependent on

several factors, including feed and operating severity.

Therefore, a high level of experience is needed to

optimise catalyst designs.

Example one

The following example illustrates the benefits

achieved by a US refiner operating two identical

reactor trains in parallel, one with an all CoMo

catalyst system (DC-2635) and the other with a

‘sandwich’ system (DC-2635/DN-3636/DC-2635). This

is a medium pressure (500 – 700 psig), moderate

liquid hourly space velocity (LHSV) (0.75 – 1.25 hr

-1

)

ultra low sulfur diesel (ULSD) unit processing an

80/20 blend of straight run diesel and light cycle oil

(LCO). The relatively low hydrogen partial pressure of

the unit would often drive the general misconception

that the application of a NiMo catalyst is not

appropriate for this particular ULSD unit. In fact, the

inclusion of a layer of NiMo catalyst offers an

activity advantage, which translates to improved

cycle life. A pilot test was conducted to confirm the

concept and quantify the benefit; the ‘sandwich’ load

was 14˚F more active than the CoMo (Figure 2).

The commercial performance (Table 1) was in line

with the pilot test with an 11˚F start of run (SOR)

weighted average bed temperature (WABT) advantage

for the ‘sandwich’ system (train B), even with higher

feed N and heavier T90. Due to the improved

activity, train B has more flexibility to target lower

product sulfur and increase feed severity as overall

refinery demands shift.

Example two

A second ULSD unit wanted to increase cycle length

from 9 to 12 months, to synchronise with reformer

regenerations and to work within strict H

2

availability limitations to maximise overall refinery

diesel yields. By upgrading the catalyst from 100%

CoMo to first generation CENTERA

TM

and then to a

second generation CENTERA sandwich system, the

site was able to meet the target cycle life while also

significantly increasing feed rate and straight run

(SR) diesel and LCO cutpoints for improved refinery

economics (Table 2). The sandwich system enabled

these improvements with only a nominal 5%

increase in H

2

consumption compared to 100%

CoMo.

Table 1.

Benefit of a sandwich system in commercial

operation

Train A (CoMo

DC-2635)

Train B (Sandwich

DC-2635/DN-3636/

DC-2635)

Feed nitrogen

Base

+ 70%

Feed T90 (˚F)

Base

+ 8˚F

nWABT HDS (˚F)

Base

- 11˚F

Figure 1.

Nitrogen removal profile.

Figure 2.

Pilot test results showing the benefit of a

sandwich load.

Table 2.

Performance of second generation sandwich

system

Previous

generation

100% CoMo

First

generation

sandwich

Second

generation

sandwich

WABT for 8 ppm

sulfur (˚F)

Base

Base – 4

Base – 14

Hydrogen

consumption

(ft

3

/bbl)

Base

+ 1%

+ 6%

Feed rate (bpd)

Base

+ 12%

+ 35%

LCO T90 (˚F)

Base

+ 30

+ 45

SR diesel T90 (˚F)

Base

+ 28

+ 30

Cycle life (months)

9

14

14 +