41

March

2017

HYDROCARBON

ENGINEERING

F

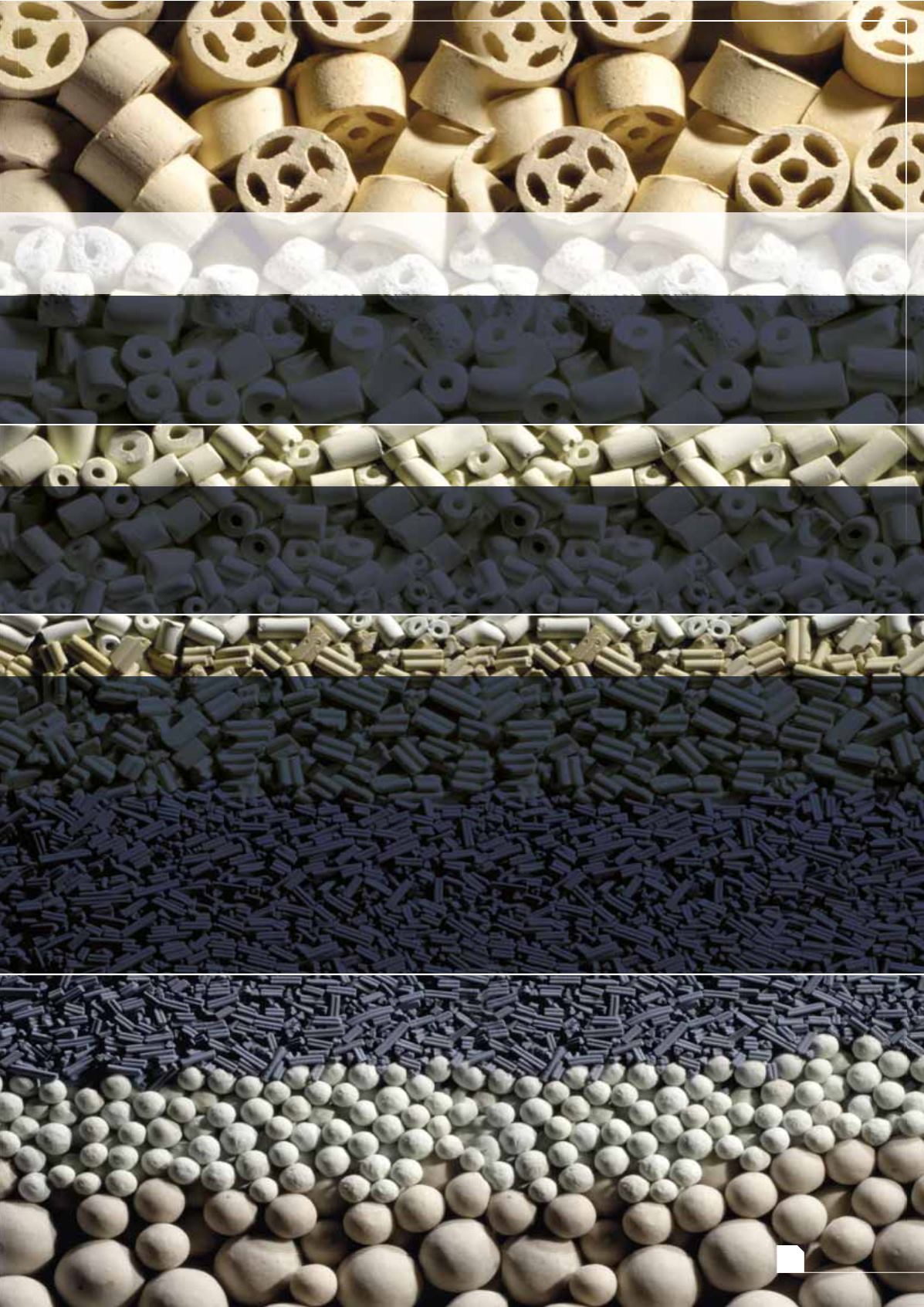

rom the first introduction of stacked catalyst

systems in the mid-1980s to the current solutions,

Criterion has long been employing such solutions to

the refining industry. The synergy offered by the

strategic application of nickel-molybdenum (NiMo) and

cobalt-molybdenum (CoMo) catalysts greatly improves the

hydrogenation horsepower of a catalyst system. This

increase in hydrogenation enables deep hydrodenitrification

(HDN) and aromatics saturation for enhanced

hydrodesulfurisation (HDS) performance along with

maximum hydrogen uptake for the highest overall yields.

Criterion Catalyst & Technologies' testing and commercial

experience with a range of different feedstocks has

demonstrated that a NiMo/CoMo stacked design results in

performance that can exceed that of 100% NiMo or 100%

CoMo catalyst systems. Applying a NiMo catalyst in the

upper part of the reactor to reduce nitrogen and

polynuclear aromatic (PNA) levels tends to ‘unlock’ direct

HDS reaction paths in the lower part of the reactor. The

direct-path HDS reactions consume less hydrogen and

result in boiling point shift and volume swell without a

significant increase in naphtha yields.

Custom stacked solutions

Ultra low sulfur diesel

HDS reactions occur rapidly in the upper section of a distillate

hydrotreater and may advance up to 80% completion.

James Esteban and Wes Whitecotton, Criterion Catalysts & Technologies,

USA,

discuss how stacked catalyst systems can improve catalyst system

stability and cycle longevity.

STABLE

STACKING