March

2017

HYDROCARBON

ENGINEERING

100

degrees above the reference temperature, the cooling cycle

is short. This new kinematic viscosity analyser has many

advantages, including low pricing.

Results

In this section, the tests that were performed on the

analyser to evaluate stability and analytical performance

are detailed, namely: accuracy, repeatability and

reproducibility.

Results on reference product

One must consider how other technologies that are used

to measure kinematic viscosity evaluate the repeatability

and accuracy. Most technologies rely on two separate

analysis, one for dynamic viscosity and one for density. This

means that the repeatability of the analyser needs to take

into account the error on both measurements. Often, only

the repeatability and accuracy data for dynamic viscosity

are published, as the error on density is considered low. For

the purpose of this study, it was decided to directly publish

the performance obtained for kinematic viscosity.

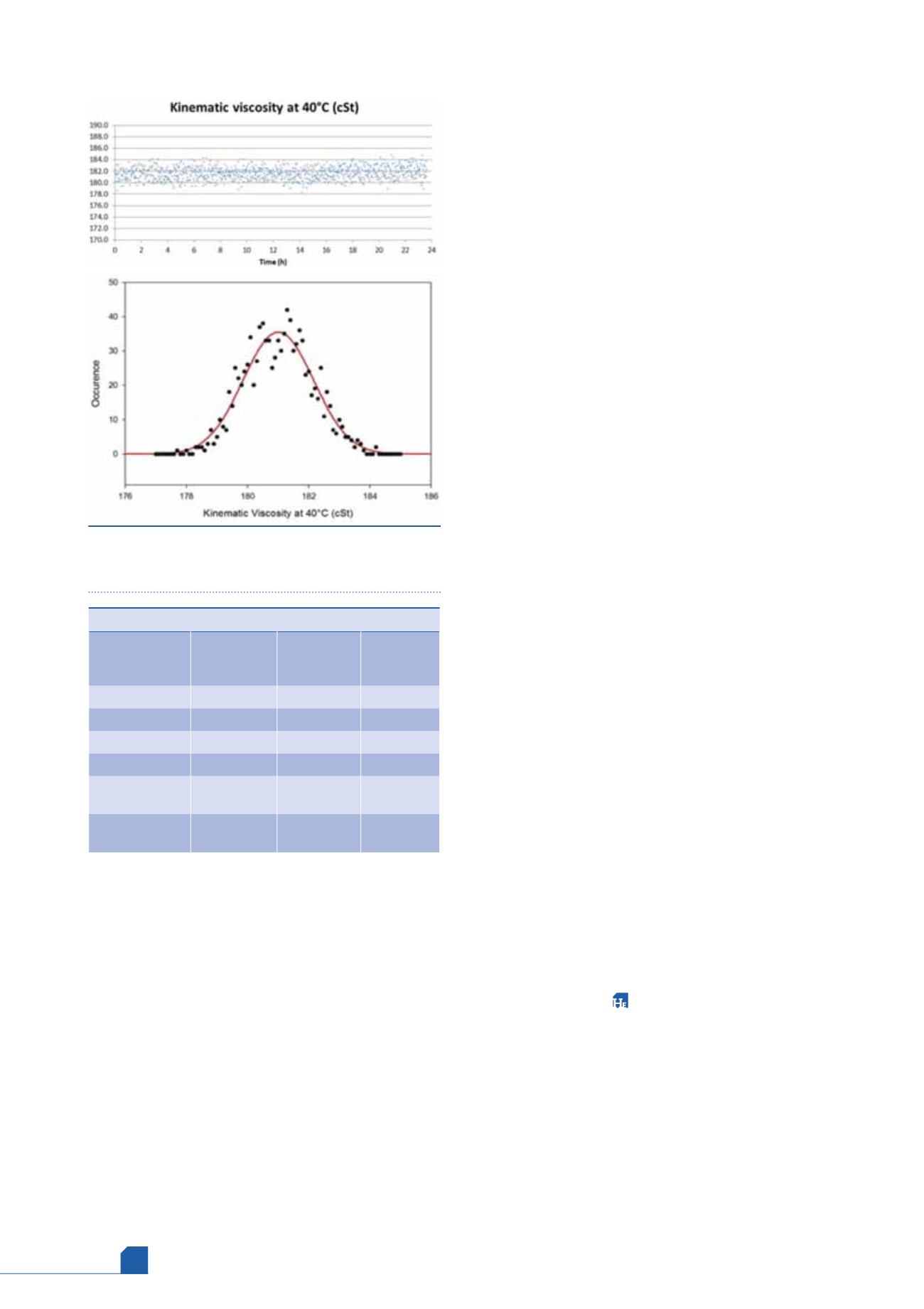

In order to evaluate repeatability, the analyser ran for

24 consecutive hours. The analyser directly calculated

real time kinematic viscosity. Figure 4 presents the

recording over 24 hours for kinematic viscosity using the

new analyser along with the statistical distribution.

These tests show that under repeatability conditions,

the standard deviation of the measurements made by the

analyser is 0.6% of the reading (for an expected viscosity of

182.6 centistokes [cSt], the standard deviation is 1.09 cSt).

The repeatability limit (i.e. the value less than or equal to

which the absolute difference between two test results

obtained under repeatability conditions may be expected

to be with a probability of 95%) is equal to 1.2% of the

reading (twice the standard deviation).

The heat exchanger at the inlet of the analyser ensures

that the measurement is made under repeatability

conditions at all times. This means that, for this specific

measurement, repeatability and reproducibility can be

considered as the same value. Hence, the reproducibility of

the analyser is set to be at 1.2% of reading.

The analyser is designed to operate around a specific

operating point (one target viscosity at a specific reference

temperature). The analyser is therefore calibrated in order

to ensure that at the operating point, the measurement is

as close to the viscosity of the reference product as

possible. Based on this, the reproducibility limit and

accuracy are considered to be identical, which gives an

accuracy of 1.2% for the measurement. Table 1 summarises

the results of the tests.

Conclusion

At the beginning of this article, the problems with online,

real time measurement of kinematic viscosity were

explained, and the main existing technology and its

weaknesses were presented.

In order to solve the issues raised in the previous

sections, the article outlined how a technology used to

measure dynamic viscosity was adapted to also measure

density and kinematic viscosity. This technology was also

adapted into a new analyser to measure kinematic viscosity

at reference temperature.

The performance of this new analyser can be correlated

to the ASTM D445, which corresponds to the needs of

most customers. This new analyser therefore brings a new

solution to customers to carry out a kinematic viscosity

measurement of the same sample for both dynamic

viscosity and density.

References

1. HALLIKAINEN, K. E., ‘Viscosmetry’, Instruments and Control System,

(November 1972).

2. ASTM D445-15a (2005): ‘Standard test method for kinematic

viscosity of transparence and opaque liquids (and calculation of

dynamic viscosity)’.

3. FR2 911 188, Sofraser, ‘Procédé et système mettant en oeuvre un

élément oscillant pour déterminer les caractéristiques physiques

d’un produit’, (1985).

4. FR2 921 826, Sofraser, ‘Method and system for determining the

viscosity of a product’, (1992).

5. FR 13 62 507, Sofraser, ‘Système et procédé de mesure en ligne de

la viscosité d’un produit’, (1986).

Table 1.

Summary of test results

Density at

40˚C (g/cm

3

)

Dynamic

viscosity at

40˚C (mPa . s)

Kinematic

viscosity at

40˚C (cSt)

Reference value 0.8276

151.1

182.6

Mean value

0.8297

150.64

181.55

Mean error

0.0021

0.46

1.05

Mean error (%)

0.3%

0.3%

0.6%

Standard

deviation

0.0011

0.73

1.09

Standard

deviation (%)

0.1%

0.5%

0.6%

Figure 4.

Recording of kinematic viscosity over

24 hours (top) along with statistical distribution

(bottom).