March

2017

HYDROCARBON

ENGINEERING

98

Analyser design

Vibrating technology used

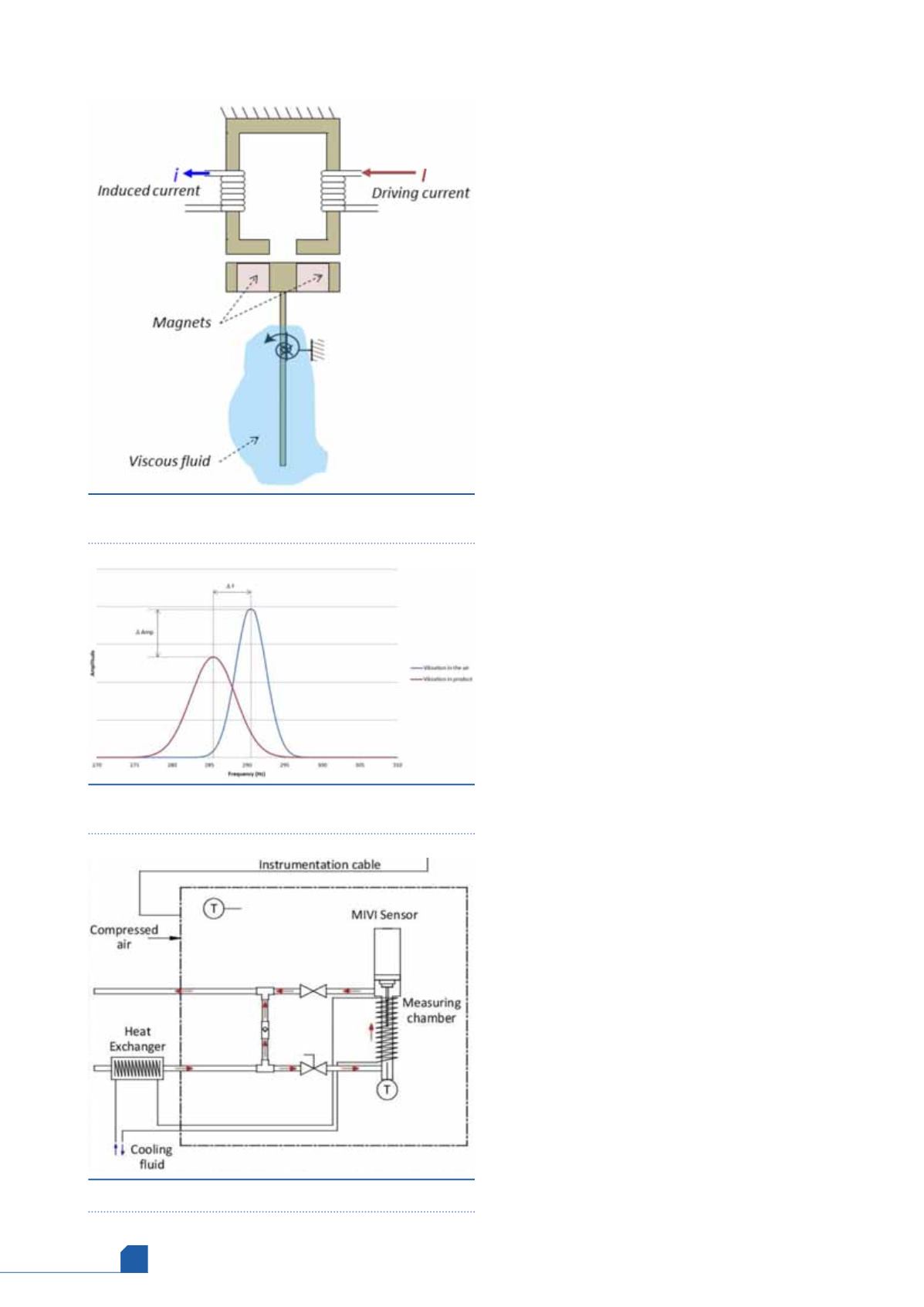

In 1981, Sofraser created and patented the first vibrating

viscometer using the vibrating technology at resonance

frequency (Patent N° FR 2 544 496).

3

The active part of the

sensor is a vibrating rod held in oscillation at its resonance

frequency (Figure 1).

When a rod immersed in a fluid is held in vibration at

resonance frequency, the vibration changes and evolves

depending on the fluid. A variation of the amplitude can

be seen (

Δ

Amp) but also of the resonant frequency (

Δ

F).

Figure 2 shows the amplitude and frequency shift from air

when immersing the vibrating rod in a liquid product.

During calibration, the amplitude of the vibration is

correlated to the viscosity of the product by comparing

the vibration in the air (maximum vibration) and in the

viscous product, thus providing a reliable, repeatable and

continuous viscosity measurement. This principle is

described in patents FR 2 911 188 B1

4

and FR 2 921 726 B1.

5

The amplitude variations correlate to the dynamic

viscosity of the fluid. A relationship

Δ

Amp = f(

η

) was

established in the past, which allows for the measurement

of dynamic viscosity of fluids. The variation of frequency

is made possible by the resonant state at which the

viscometer operates, as opposed to other types of sensor

using a known set frequency to operate. The resonant

frequency depends upon the characteristics of the

oscillator and the medium characteristics (viscosity and

density) in which the rod vibrates. The medium acts as a

buffer, dampening the motion of the rod (and hence, its

frequency). The Sofraser sensor is then able to directly

determine the kinematic viscosity, the dynamic viscosity

and the density by measuring amplitude, frequency and

temperature.

New analyser design and adaptation of

vibrating technology

In order to stabilise the temperature of both product and

sensor, a first heat exchanger is inserted before the

product inlet of the analyser (Figure 3). This first heat

exchanger allows the temperature of the product to be

brought within a few degrees of the reference

temperature. The coolant used in the first heat exchanger

is supplied by a water chiller to allow the coolant

temperature to rest at a few degrees above the reference

temperature.

Once the product exits the first heat exchanger, its

temperature is a few degrees above the reference

temperature. The temperature of the product is

monitored continuously as it exits the heat exchanger. If

the temperature of the product is the same as the

reference temperature (within an acceptable limit) and it

reaches the sensor, the product flows through the

flow-cell and the kinematic viscosity measurement at

reference temperature is made continuously.

If product temperature is too high with regards to the

reference temperature, the product is locked into the

flow-cell (on a bypass loop) and is allowed to cool to the

reference temperature. As the product is only a few

Figure 1.

Principle of the vibrating viscosity sensor at

resonance frequency.

Figure 2.

Frequency and amplitude shift between air and

liquid product.

Figure 3.

New analyser schematic.