rely on calibration data stored inside the smart load cell.

During operation, periodic recalibration with test weights

– usually once a year – is recommended to ensure the

traceability of the measurement result.

As mentioned, a simple analogue load cell may be the

right choice for a specific application, exactly as an

hourglass is sufficient in certain situations for measuring

time. However, especially for critical processes, it is crucial

to select measuring devices based on a verifiable method.

Only then can adherence to process tolerances and

regulatory requirements be guaranteed long-term.

Connecting via the cloud

Particularly when a weighing application is critical to

productivity, revenue generation or

quality, microprocessor-enabled

load cells and complementary

terminals with predictive

maintenance features offer the

option of automatic communication

to a third party service provider. This

can allow a service team to either

diagnose issues from a distance or

dispatch a service team if necessary

– sometimes, even before the

company itself has determined there

is a problem to be addressed.

So-called cloud-based

monitoring can be a secure part of

giving users real time access to their

own system data via the internet,

while allowing service providers to

respond rapidly to service issues. In

conjunction with a supportive

weighing terminal, cloud-hosted

software can be used to monitor the

status, operating parameters and

configuration of a production

facility’s weighing equipment.

Equipment performance can also be

catalogued and stored for trend

analysis. If a problem is detected, the

remote support technician can

diagnose the issue by analysing data

remotely without interruption to

operations.

If corrective action is required,

the technician can, with operator

permission, remotely access the

microprocessor-enabled equipment

and work on the system directly,

potentially correcting the issue on

the spot. However, if a service

technician needs to be sent to the

facility to repair the problem, as

noted, information collected

through the remote system helps to

ensure that they arrive on site with

the necessary parts and knowledge

to resolve the issue.

Issues that should be able to be communicated to the

service provider by the right solution include:

Loss of load cell communication.

Scale failure.

Calibration errors, including recalibration interval

expiration.

Load cell enclosure breach.

Zero drift error, cell overload error and scale

overcapacity.

Critical supporting diagnostics information (such as the

condition of scale electronics).

For an interactive relationship to be helpful, however,

the relationships between service providers must have the

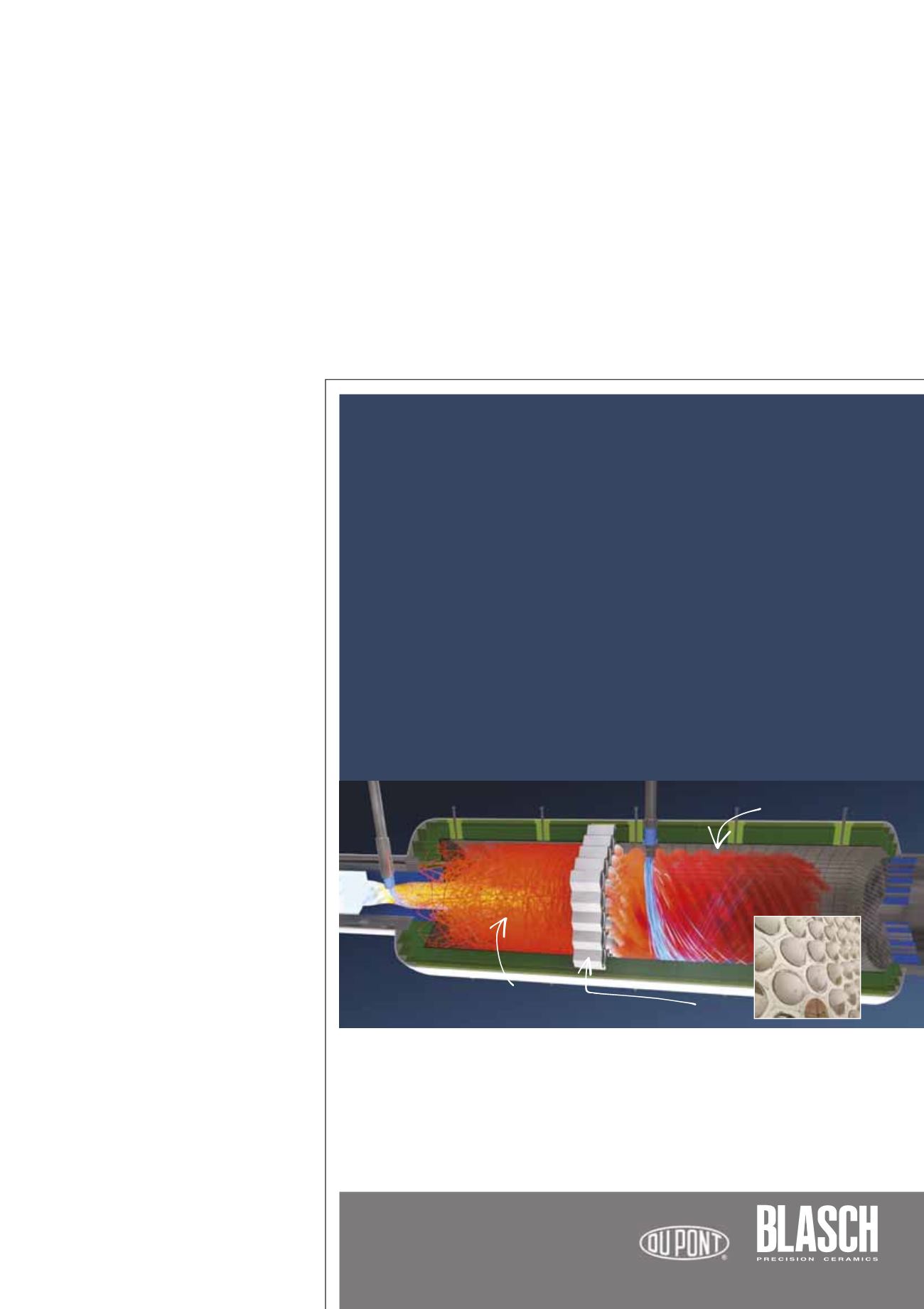

Push 30% more acid gas

through your furnace

Destroy as much as 50% more NH3 and

BTX in the high temp mixing zone

Contact us today to design a VectorWall

WKDW ZLOO ƬW \RXU H[DFW UHTXLUHPHQWV

800-550-5768 /

+1-518-436-1263

EODVFKFHUDPLFV FRP

It’s about

Time

Temperature

and

Turbulence

Blasch VectorWall

TM

1

0D[LPL]H $PPRQLD RU %7; GHVWUXFWLRQ ZLWK KRWWHU PRUH

HƪHFWLYH =RQH PL[LQJ

2

2SWLPL]H UHVLGHQFH WLPH GLVWULEXWLRQ DQG LQFUHDVH

WKURXJKSXW ZLWK URWDWLRQDO ƮRZ SDWWHUQ

:KHWKHU \RXpUH IDFHG ZLWK VLPSOH RU FRPSOH[ FRPEXVWLRQ

FRQƬJXUDWLRQV UHDOL]H VLJQLƬFDQW SURFHVV LPSURYHPHQWV

ZLWK WKH %ODVFK 9HFWRU:DOO

™

The best 2-stage solution

for ammonia destruction

in the business