March

2017

HYDROCARBON

ENGINEERING

90

focused on making these results easier and faster to

obtain.

Case study: thermodynamic hydrate

inhibitors

The story starts upstream, where MEG and

methanol are used as thermodynamic hydrate

inhibitors. However, once they have fulfilled their

function, these two chemicals become undesirable

in produced fluids.

Methanol is most commonly used at the point

of startup and when production conditions enter

the hydrate envelope, so regeneration is seldom

used. Methanol partitions readily to the water

phase, and is largely discharged to sea with

produced water. Small percentages also partition to

the oil phase where it can have negative impacts on

downstream operations. This means production

during these periods often has to be deferred or

quarantined, so an operator needs to be able to

isolate the affected product. Analysis of methanol

content in oil over time is used to detect the

passing of the methanol slug, and thus it offers

great benefit to the operator to be able to obtain

results quickly, to track the slug in near real time.

Any time delay may be costly as unexpected

methanol levels can have adverse fiscal

consequences.

Downstream, whilst the refinery will attempt to

wash the crude of methanol, significant quantities

of methanol can damage or destroy the sensitive

microorganisms used to treat the effluent water,

damaging the efficacy of this system, and

potentially leading to costly repair operations. To

mitigate some of this risk, refineries will often pass

this cost back to the producer by imposing high

waiver fees on contaminated crude. In this scenario,

both the crude producer and refinery stand to

benefit from accurate knowledge of the methanol

concentration in the crude. Delays in receiving test

results can mean the possibility of the crude

already having arrived at the refinery, waiver fees

being imposed and the damage being done.

In much the same way as methanol, MEG is a

known contaminant and a potential source of issues

during processing at refineries. Although MEG also

more readily partitions into the water phase than

the oil phase, the MEG in a crude shipment also has

a damaging effect on the sieve beds at the refinery.

Typically, large amounts of MEG are continually

injected to prevent hydrate formation in flowlines.

Given the high cost of MEG, replacement is often

not feasible, so regeneration and re-injection is

often chosen as the most cost effective option.

During the regeneration process, MEG is

separated from the crude through a process of

heating and recovery from residual water. This

process leaves the system open to MEG losses

through two main channels; the MEG that remains

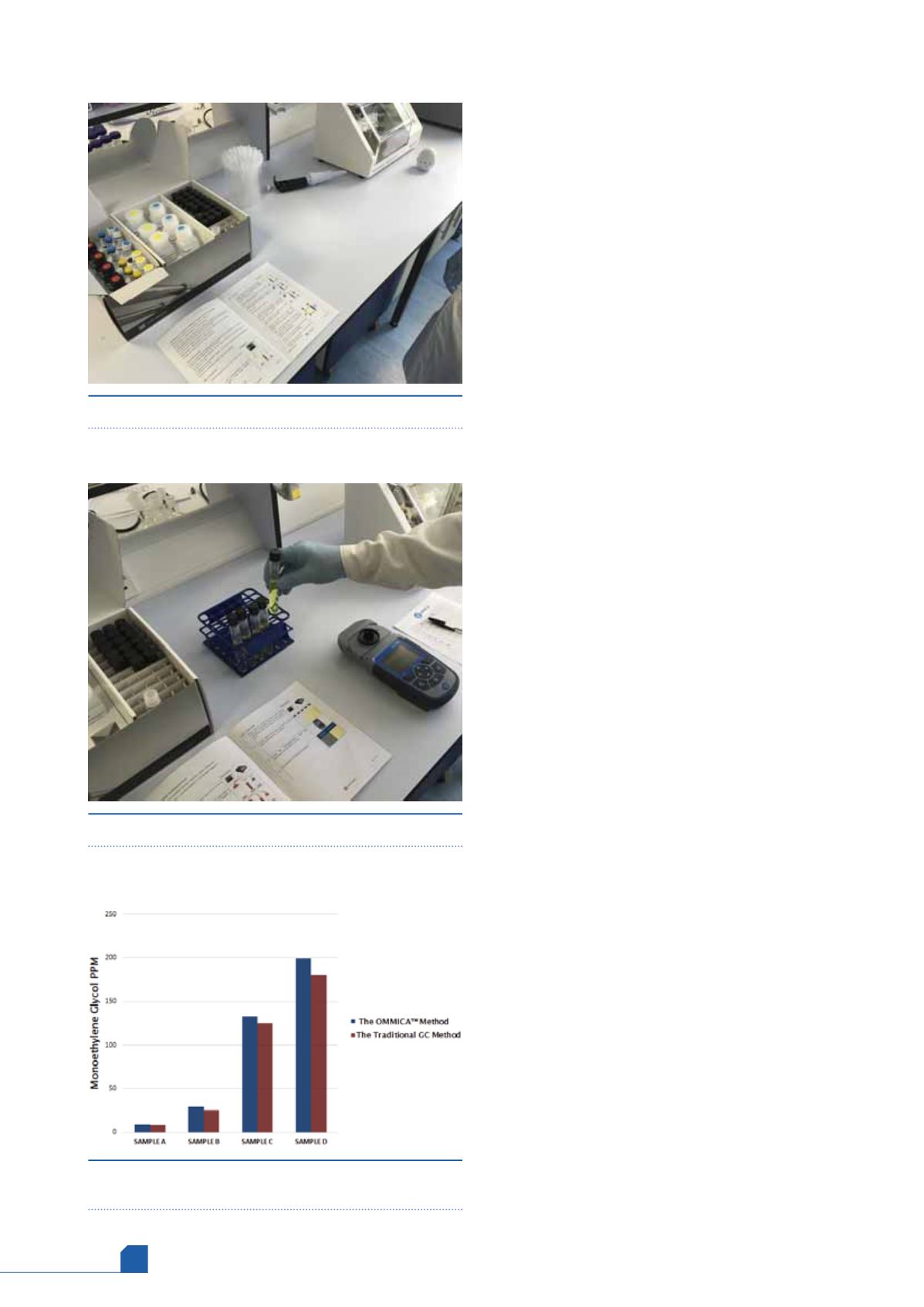

Figure 1.

Setting up for using OMMICA.

Figure 2.

OMMICA testing underway.

Figure 3.

Correlation of the samples using OMMICA

method and GC in an independent laboratory (ppm).