March

2017

HYDROCARBON

ENGINEERING

60

Step 2: simultaneous conversion of DME

and butanes to light olefins over a fixed-bed

catalyst

In the second step, DME and butanes are reacted

simultaneously to form light olefins such as ethylene,

propylene, butylene, and mixtures thereof, over promoted

solid-acid catalysts. The conversion of DME to olefins is

an exothermic reaction (

Δ

H = - 55 kJ/mole) while the

dehydrogenation of butanes to olefins is an endothermic

reaction (

Δ

H = 120 kJ/mole). Coupling the two reactions

simultaneously, by reacting two moles of DME per mole

of isobutane in the ideal case scenario, allows one to

design a simple, thermo-neutral process (Figure 2). This

allows for a simpler reactor design, and increases butane

reactivity.

Step 3: alkylating the resulting light olefins

with isobutane

Using a technology currently being commercialised, the

Exelus technology uses an environmentally benign precious

metal free proprietary solid-acid catalyst called ExSact-E.

This catalyst facilitates the reaction of isobutane with a

variety of light olefins, including ethylene, which cannot be

alkylated with traditional refinery alkylation technologies

that utilise liquid acids. Additionally, the Exelus alkylation

technology employs two adiabatic fixed bed reactors and

provides higher yields and octanes than can be achieved

utilising the conventional liquid acid alkylation processes.

The main advantages of the Exelus process over

conventional MTG processes are as follows:

Adiabatic operation: the exothermic heat of reaction

for the DME to olefins reaction is exactly matched by

the endothermic heat of reaction for isobutane to

olefins.

Alkylate contains no aromatics and, hence, no durene.

The octane number for the alkylate is significantly

higher than the MTG process (MON +8 points).

By co-reacting cheap mixed butanes with a more

expensive methanol feed, the overall raw material

costs are cut by nearly half.

Converting butanes and oxygenates to

olefins

Exelus has developed a unique engineered catalyst capable

of generating light olefins simultaneously from both

isobutane and DME. The catalyst has been designed with

carefully chosen pore structure and acid site density and

distribution to optimise olefin production while minimising

paraffin or aromatics production.

The catalyst performance is shown in Figure 3. DME

conversion remained constant at 100% for over 24 hours

while the light olefin selectivity (ethylene, propylene and

butenes) remained >75 wt%.

Production of alkylate using solid-acid

catalyst

In the final step, olefins produced from DME/butanes are

then reacted with isobutane to produce high octane

alkylate. One challenge with olefins produced via the

DME/butanes reaction is ethylene. The reactivity of

ethylene is considerably different from that of butenes

typically used for refinery alkylation. In conventional

hydrofluoric acid (HF) or H

2

SO

4

alkylation processes,

ethylene forms stable ethyl ethers, rather than the

desired isoparaffins. Using the standard ExSact catalyst,

ethylene would alkylate to form isohexane. To improve

alkylate octane when processing feedstocks containing

ethylene, Exelus has developed an innovative

bi-functional catalyst, ExSact-E, in which ethylene is first

dimerised to butenes. The highly reactive butenes are

then converted to alkylate in the presence of isobutane.

This approach has the advantage of producing an

isooctane molecule with good properties rather than

isohexane molecules. Performance of this catalyst is

shown in Figure 4.

Product quality

The product of the M2Alk process is mainly high octane

isoparaffins with low vapour pressure, low aromatics, as

well as very low sulfur content. Starting in 2017, the

EPA Tier 3 rule will set new vehicle emissions standards and

lower the sulfur content of gasoline from 30 ppm to

10 ppm. This will present new octane and sulfur challenges

to many refineries. The catalyst adsorbs sulfur molecules,

thereby producing an alkylate product with below 1 ppm

sulfur species – allowing refiners that are short on olefins a

viable route to meet Tier 3 specifications in a cost effective

manner. Table 1 compares the product quality from the

M2Alk process with a conventional MTG process.

Table 1.

Comparison of the MTG vs the Exelus

M2Alk product quality

Product quality MTG process

1

Exelus M2Alk

RON

92

93

MON

82

90

RVP (psi)

12.3

3.82

Density (kg/l)

0.73

0.7

Sulfur (ppm)

nd

<1

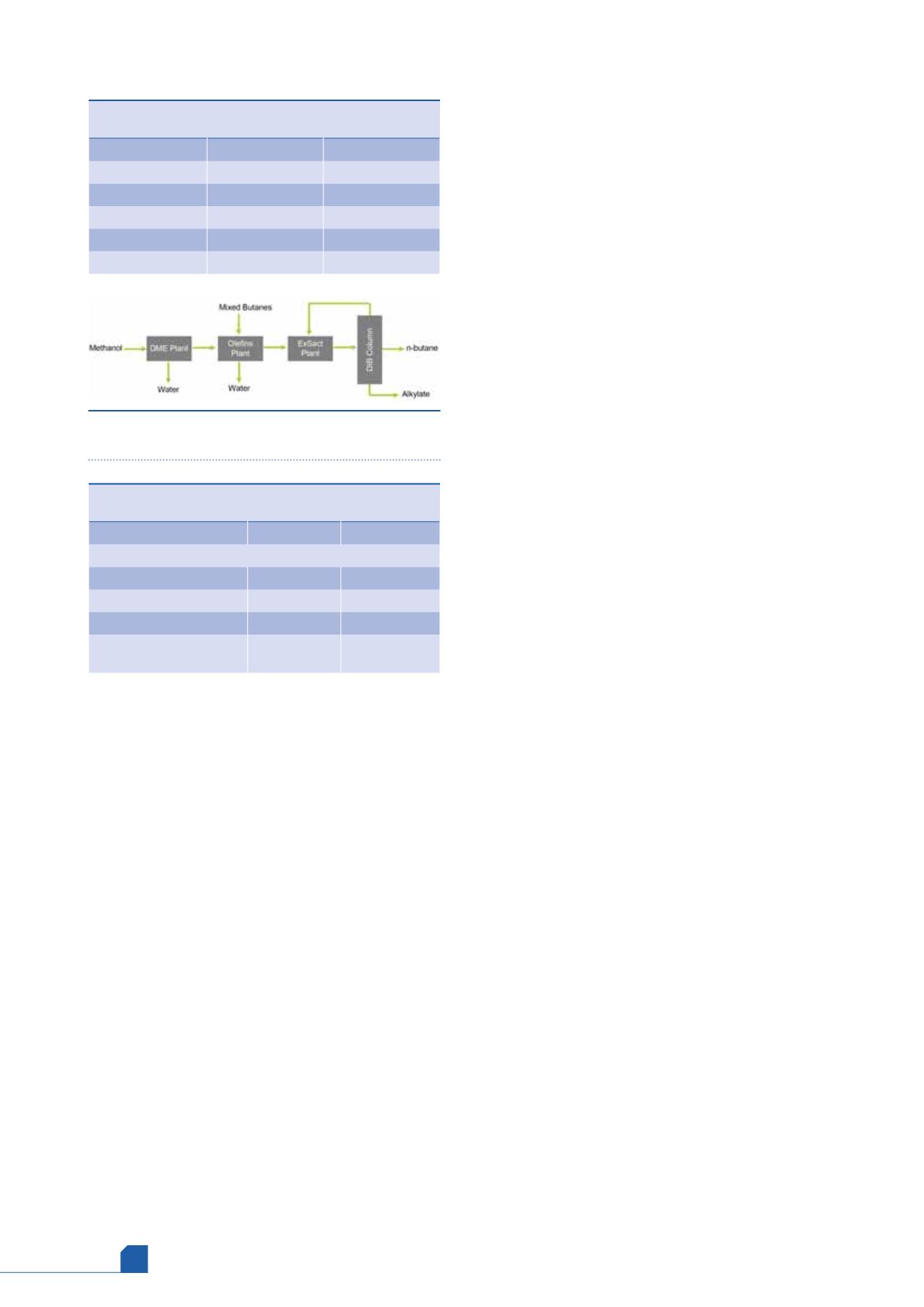

Figure 5.

Block flow diagram of the methanol/butanes

to alkylate process.

Table 2.

Techno-economic comparison of the MTG

and Exelus M2Alk process

Parameter

MTG

1

Exelus M2Alk

Raw material costs

Methanol (US$400/t)

US$2.80

US$0.67

Butanes (US$250/t)

US$0.55

Total (US$/gal.)

US$2.80

US$1.22

Capital expenses (for

15 000 bpd plant)

US$1 billion US$200 million