March

2017

HYDROCARBON

ENGINEERING

66

had similar corrosion inhibition properties when the

coupons were pre-passivated (Figure 4).

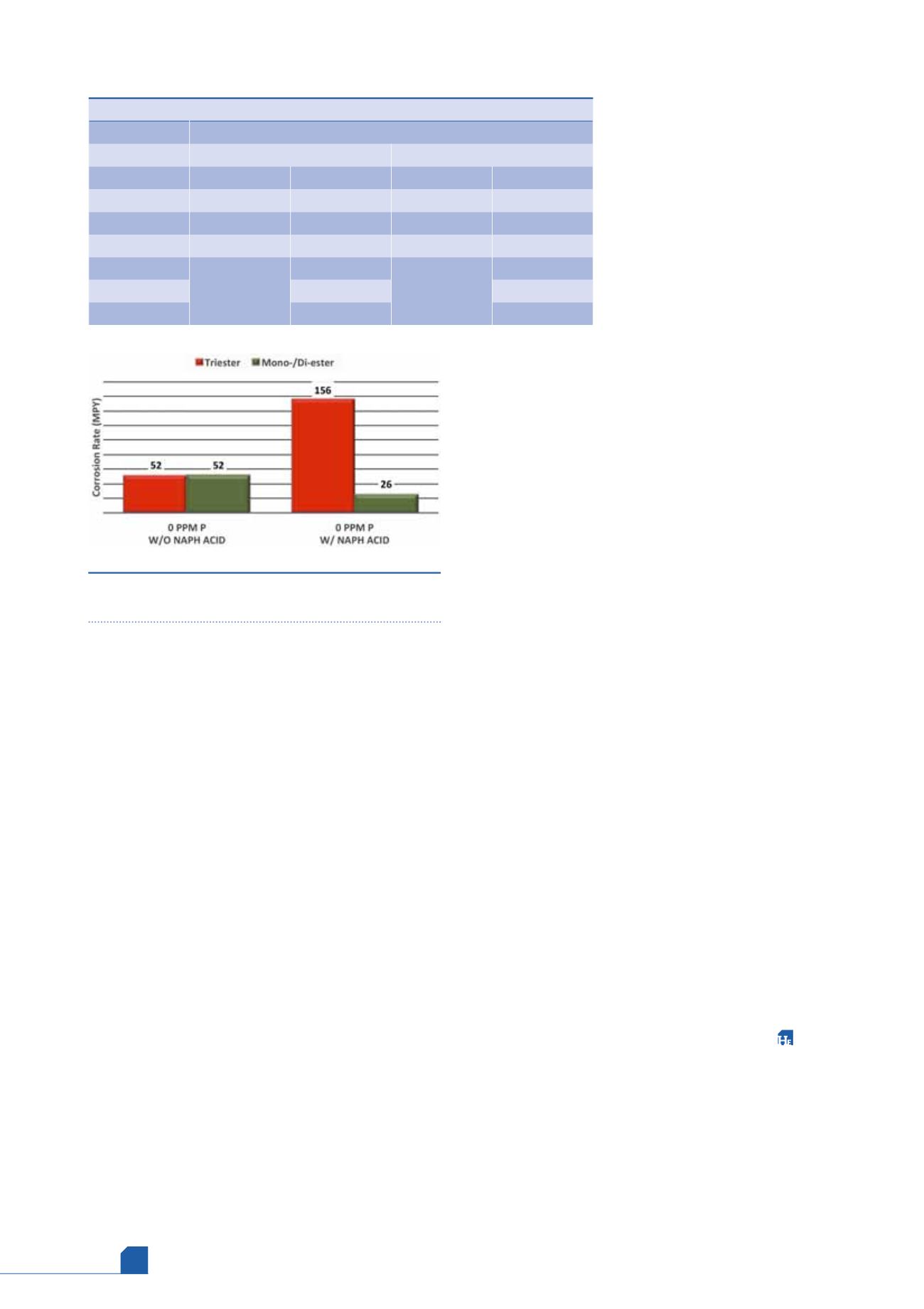

Simulating field conditions, the same experiment

was performed without pre-passivating the corrosion

coupons prior to testing in a fluid already containing

naphthenic acid. The results (shown in Figure 5) were

unexpected. The mono-/di-ester product afforded

almost 99% inhibition whereas the tri-ester product

resulted in a near 0% inhibition.

The above data clearly suggests that there is a

marked difference between the passivation layers that

are formed and this depends on the types of esters

that are in the presence of naphthenic acid. It is

expected that in the field, the passivation from the

tri-ester would be less likely to form under typical

process conditions.

To further investigate this, a dosage response test

was performed to determine if concentration could

have an effect on the ability of the esters to form

protective barriers. Table 2 shows the dosage response

required to achieve the same level of protection.

The test conditions used were the same as shown

in Figure 5, except for the dosage. Experiments were

conducted for both 4 and 12 hour durations. The

results, shown in Table 2, indicate that the amount of

the tri-ester required to provide equivalent corrosion

inhibition as mono-/di-ester would be a minimum of

2.5 times.

The data clearly shows that mono-/di-ester forms

a stronger barrier and is a more efficient corrosion

inhibitor compared to tri-ester in the presence of

naphthenic acid in simulated field

conditions.

Persistency of the

barrier layer

Persistency of the barrier layer is

important as the barriers have to

be able to exist during operating

conditions where the

replenishment of the inhibitor in

the process is not always perfectly

uniform. As such, a set of

experiments were conducted to

evaluate the persistency of the

barriers formed by mono-/di-ester and tri-ester in the

presence and in the absence of naphthenic acid. The

lubricant industry has reported that tri-ester forms a

strong physisorption film, whereas mono-/di-esters

chemically reacts and forms a strong chemical bond

with metal.

3

Chemically formed barriers such as this

should be more persistent than a physisorbed film.

In the first experiment, pre-passivation was carried

out, as in the previous experiments, without

naphthenic acid. The test was conducted for 12 hours,

5 TAN, 600 RPM at 653°F (345°C) with no additional

chemical dosage added. At the end of the

experiments, the coupons were measured for weight

loss.

In the second experiment, pre-passivation was

carried out as in the previous experiments, in the

presence of naphthenic acid with an approximate TAN

of 5. The rest of the procedure remained the same.

The results shown in Figure 6 demonstrate that

mono-/di-ester forms a stronger barrier (passivating

layer) in the presence of naphthenic acid compared to

tri-ester. The tri-ester was generally unable to form a

protective barrier in the presence of naphthenic acid

equivalent phosphorus dosage.

Summary

The use of phosphate esters-based inhibitors still

dominates the field of naphthenic acid corrosion

control by chemical additives. There are significant

differences in performance between the various esters

and this should be considered when selecting the type

to be used in the industry. The mono-/di-ester-based

additives demonstrate the most desirable

characteristics to control naphthenic acid attack in the

form of effective laydown efficiency and the formation

of a tenacious, persistent passivation barrier on the

metal surfaces found in refinery process units.

References

1. BABAIAN-KIBALA, E., ‘Phosphate Ester Inhibitors Solve

Naphthenic Acid Corrosion Problems’,

Oil & Gas Journal

,

Vol. 92, Issue 9, (28 February 1994).

2. ZETLMEISEL, M. J., ‘Naphthenic Acid Corrosion and its Control’,

NACE 96, paper No. 218.

3. BARABANOVA, G. V., IVANOV, V. I., KOSSAOVA, L. V. and

AKIMOVA, N. S., ‘Use of esters of acids of phosphorus as

lubricity additives for high-temperature synthetic lubricating

oils’, Chemistry and Technology of fuels and Oils, Vol. 12,

Issue 5, (May 1976).

Figure 6.

Dynamic test conditions and results –

barrier persistency test.

Table 2.

Dynamic test results – tri-ester and mono-/di-ester dosage profile

Corrosion rate (mils per year)

ppm P

4 hours

12 hours

Mono-/di-ester Tri-ester

Mono-/di-ester Tri-ester

Blank

264

264

166

166

10

150

300

116

161

40

0

242

0

164

50

230

154

70

Did not run

2

100

0

0