March

2017

HYDROCARBON

ENGINEERING

64

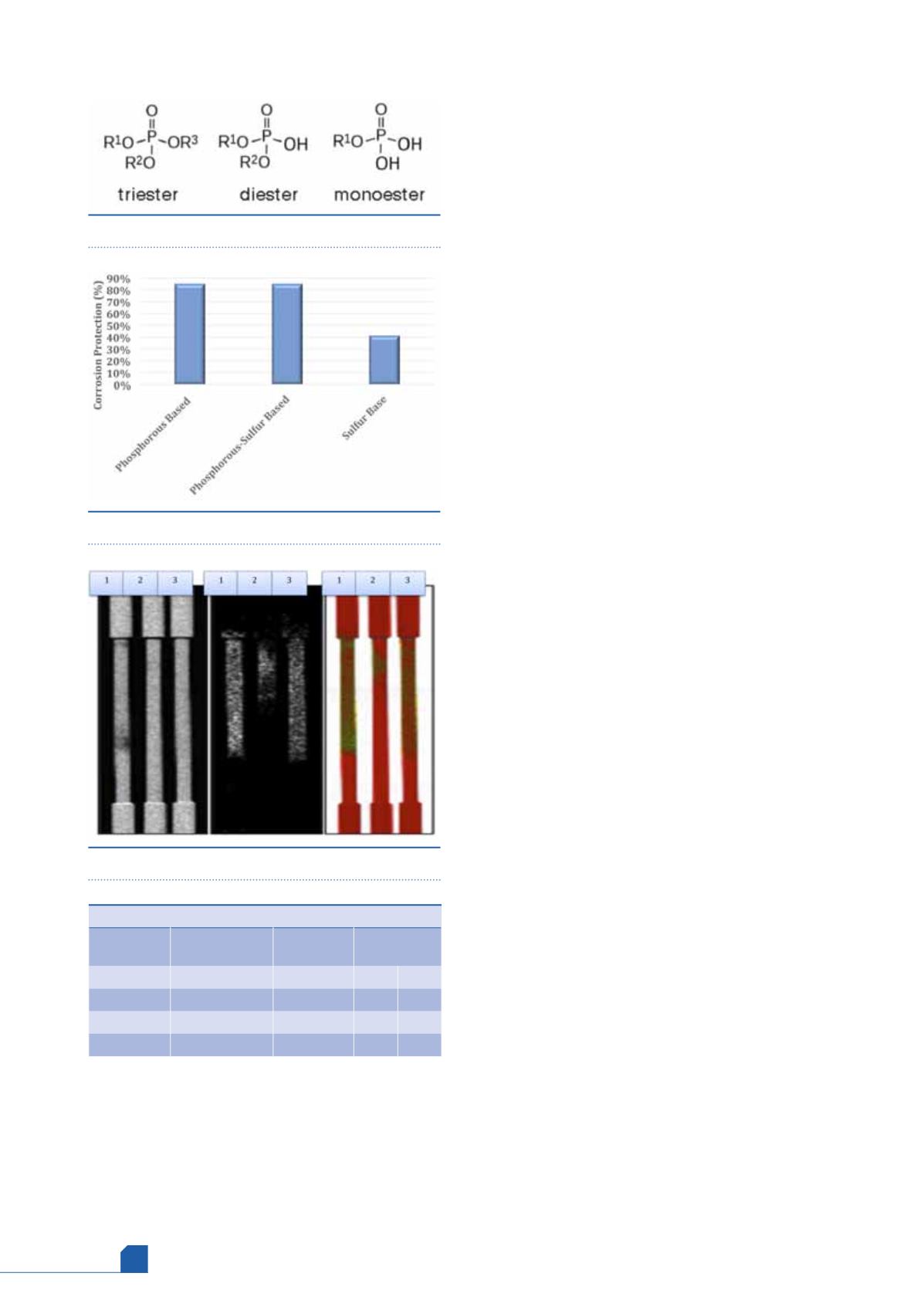

interferes with the reaction of naphthenic acids with

metallurgies composed of iron and iron alloys. Instead of

forming the hydrocarbon-soluble iron naphthenate,

insoluble iron phosphate is produced, thus protecting the

iron from metal surface leaching away. The presence of

more than one active site on the phosphorus atom

enables one molecule to react with more than one iron

molecule. This interaction eventually results in the

formation of a tenacious passivation layer on the metal

surface, which prevents naphthenic acid attack on the

metal.

1

The most common form of these phosphate

ester-based products are a mixture of mono- and

di-esters. These forms readily activate at stream

temperatures where naphthenic acids are observed to

be the most aggressive. This is the basis of most of the

successful naphthenic acid inhibitors deployed to date

in the industry. Other materials have been evaluated in

the laboratory with lower performance results, and

besides the use of reactive polysulfides they have not

been commercially deployed. Reactive polysulfides

have limited use in high temperature naphthenic acid

corrosion control and whilst they can provide some

protection against naphthenic acid, they are of a lesser

application capability compared to phosphorous-based

products on an equivalent basis (Figure 2).

2

Recent in-house studies on the relative

performance of a mono-/di-ester and a tri-ester-based

product has demonstrated the additional functional R

group on a tri-ester can hinder several key performance

parameters that can impact the effectiveness of these

types of inhibitors. Three of the most important

characteristics are laydown efficiency, the ability to

passivate and protect in a dynamic situation, and

persistency of the barrier layer

Laydown efficiency

For products to be effective, they need to be able to

react with the metal surfaces when they are injected

into the process stream. Using an Alcor Hot Liquid

Process Simulator (HLPS), the effectiveness of the

laydown between the mono-/di-ester and the tri-ester

was demonstrated. The Alcor HLPS is a single-phase,

laminar flow tube-in-shell heat exchanger that can be

used to simulate deposition or surface reaction effects

of components in crude oil and intermediate

products. The fluid is pumped across a heated tube

under controlled conditions, material in the fluid may

react with the surface of the heated tube and fouling

deposits may also be deposited on the heater tube

surface. The effect of the deposits on the heat

exchanger efficiency is measured by monitoring the

fluid temperature as fluid exits the heat exchanger. The

absolute amount of deposits on the heater tube is also

measured.

Several HLPS runs were conducted with the

following conditions:

Temperature: 680°F (360°C).

Flow rate: 2 ml/min.

Duration: 4 hours.

The heater rods were removed and analysed using

X-ray fluorescence microscopy (XRFM) analysis. This

analysed the amount of phosphorous that reacted with

the metal rod surface. The more the phosphorous was

detected, the higher laydown.

Figure 3 is a picture of the heater rods from the HLPS

and Table 1 provides the XRFM quantitative results. Figure 3

Table 1.

HLPS heater rod results

Rod number Description

Chemical

dosage

Results (%)

Fe P

1

Mono-/di-ester 1 wt%

88.6 11.4

2

Tri-ester

1 wt%

96.7 3.3

3

Mono-/di-ester 0.05 wt% 87.1

12.9

Figure 1.

Esters of phosphoric acid.

Figure 2.

Corrosion protection.

Figure 3.

HLPS heater rod.