March

2017

HYDROCARBON

ENGINEERING

58

including low energy density and infrastructure

requirements. Methanol to gasoline (MTG) technologies have

been tested in commercial situations, including at

ExxonMobil’s MTG plant in New Zealand in the 1980s.

Increasing restrictions on the amount of aromatics allowable

in fuels has become the major barrier to traditional MTG

processes, which make >25 vol% aromatic compounds.

Butane glut

Natural gas liquids (NGLs), which comprise mainly of

ethane, propane, butanes and natural gasoline, production

is expected to increase more than 40% over the next

five years. The increase will total approximately

950 000 bpd, with volumes reaching at least 3.1 million bpd

by 2017. While ethane and propane serve as feed for steam

crackers to make ethylene and propylene, butanes

(isobutane and n-butane) do not have a ready market

outlet. Butane is blended into gasoline in the winter but,

due to its high vapour pressure, it cannot be blended into

gasoline in the summer.

Alkylate demand

Tier 3 refers to a set of fuel and vehicle standards adopted

by the US Environmental Protection Agency (EPA) in 2014.

When implemented in 2017, the standards will immediately

reduce toxic air pollution from cars and trucks. Oil

companies must lower the sulfur content of gasoline,

making it cleaner to burn. Refiners have a limited number of

options to reduce gasoline sulfur levels to meet the new

10 ppm requirement. For Tier 3, removing the remaining,

more difficult sulfur molecules may lead to more significant

octane loss. Accordingly, alkylate has emerged as a

preferred gasoline blending component, as it contains no

sulfur, no olefins, no benzene and has a low vapour

pressure and high octane number. Alkylate is produced by

reacting isobutane with light olefins using liquid acids, and

currently US refineries produce 1.3 million bpd of alkylate

(20 billion gal./y). Unfortunately, for many refiners alkylate

production is limited due to a shortage of olefins.

Breakthrough technology

Alkylate, a mixture of isoparaffins, is produced by the

reaction of C

3

– C

5

olefins with isobutane. It is highly

valued as a gasoline blendstock because it has no olefins or

aromatics, while also having an ultra low sulfur content,

low vapour pressure and high research and motor octane

numbers. Unlike all other alkylation technologies, this new

technology developed by Exelus requires no olefin

feedstock. Instead, methanol and butanes are converted to

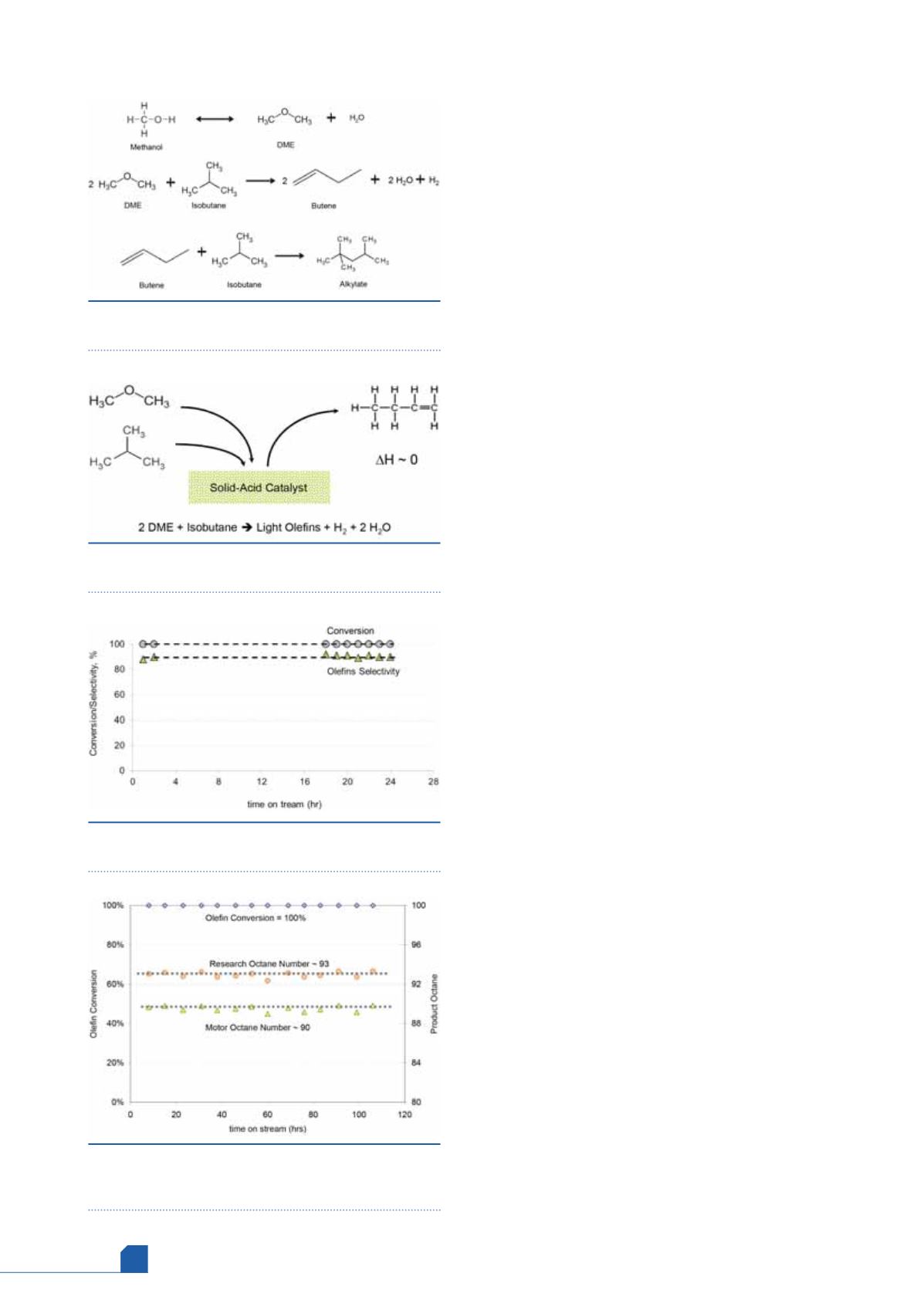

alkylate using a three step process, as illustrated in Figure 1.

Step 1: conversion of methanol to dimethyl

ether

Methanol can be partially dehydrated to an equilibrium

mixture of dimethyl ether (DME), methanol and water over

a mild solid-acid catalyst (typically gamma-alumina). This

reaction is rapid, reversible and exothermic. This is a proven

technology and DME yields greater than 99% are reported.

In cases where the starting material is DME rather than

methanol, this first step can be omitted.

Figure 1.

Main reactions in the production of alkylate

from methanol and butanes.

Figure 2.

Unique solid-acid catalyst converts DME

and butanes simultaneously to light olefins.

Figure 3.

Time on stream performance of solid acid

catalyst for olefins production.

Figure 4.

ExSact-E catalyst produces high octane

alkylate from a mixture of light olefins: mainly

ethylene, propylene and butenes.