mass produced using traditional milling processes, which

means high costs and long lead times for end-users when

replacements are needed.

In 2016, Siemens set out to solve this problem using

additive manufacturing (AM) to commercially produce

turbocompressor impellers. In October 2019, extensive quality

and stress testing were completed. The first AM units are now

ready for distribution to the market. They are designed to

improve rotor dynamics, reduce weight and product waste,

and shorten lead times from months to weeks.

Impeller manufacturing challenges

Manufacturing compressor impellers is a complex task that

often requires original equipment manufacturers (OEM) to

satisfy a multitude of competing design requirements.

First and foremost, the impeller must be able to deliver

acceptable distributions of relative velocity on the blades’

driving and trailing surfaces to prevent flow separation,

which can negatively impact performance. Secondly, after

aerodynamic characteristics have been specified, the impeller

must be evaluated to ensure that it can safely withstand

the mechanical and thermal stresses it will be subjected

to throughout its useful life. Finally, the impeller must be

designed in such a way that it can be reproduced accurately

using an automated manufacturing process.

Many large impellers today are fabricated via milling;

however, for smaller impeller wheels, conventional milling

techniques often impart too much impact on the material,

increasing the likelihood of creating structural weaknesses.

Additionally, for many high-performance and mission-critical

applications where extreme manufacturing precision is

required, the use of milling processes can result in minuscule

defects on blade surfaces, leading to separation of flow and

higher losses.

A popular alternative to milling smaller impeller wheels

has been an electrical discharge machining (EDM) process

known as erosion. Erosion is a non-contacting method that

enables machinists to achieve extremely close tolerances and

intricate contours that would otherwise not be possible with

conventional cutting processes. The primary disadvantage of

EDM, however, is that it is highly cost prohibitive. Like milling,

EDM also results in long lead times – typically to the tune of

months.

Overcoming conventional techniques

In recent years, an increasing number of companies have

begun leveraging AM processes to overcome the challenges of

conventional manufacturing techniques.

Siemens started investing in AM in 2009 to produce

critical components for gas turbines. In 2013, the company

installed the first 3D-printed burner tips and burner swirls

in gas turbines. Then in 2017, the first hot gas path blades

were successfully printed and tested. Around the same time,

3D-printed burner heads were also installed for commercial

operation. Another development came in 2018 when an

additively manufactured sealing ring was installed on a steam

turbine in commercial operation.

Siemens is now applying its knowledge of 3D printing

to commercially produce closed radial impeller wheels for

turbocompressors using an AM process based on powder bed

fusion (PBF) – also known as selective laser melting (SLM),

direct metal laser sintering, or electron beam melting.

With PBF, a 3D computer-aided design (CAD) file is sliced

into 2D elements corresponding to laser scan vector data

for each layer. A layer of metal powder with a specified

thickness is then applied over the forming platform. The

powder is melted selectively by a laser to produce the desired

component in layers. Any powder that is not melted by the

laser is brushed away from the part and collected for reuse.

In recent months, Siemens has optimised this

manufacturing process to improve the physical characteristics

of additively manufactured radial impeller wheels, such as the

surface quality of the blades. The blade channel of the first

AM impeller wheel has a so-called ‘stepping effect.’ These

steps are surface defects that lead to the creation of flow

turbulence that can reduce compressor efficiency.

Siemens has qualified a continuous process chain to

ensure the fulfillment of all quality requirements, including

an extensive non-destructive and destructive test programme

to validate the mechanical integrity of radial impeller wheels.

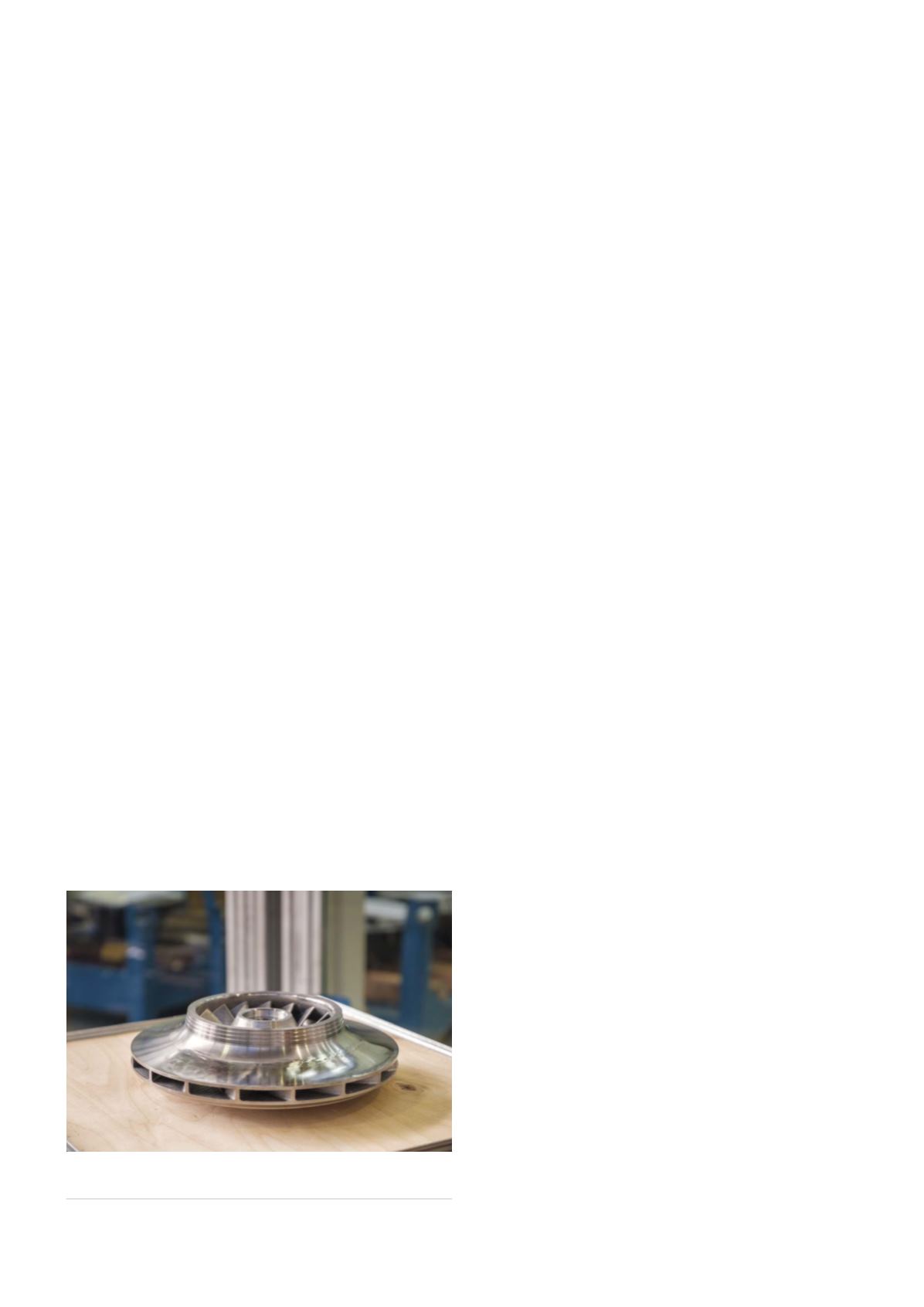

Figure 1 shows a 3D-printed impeller after a successful

overspeed test without any indication.

The company has also improved the manufacturing

process itself by proving that in a single printing run, three

separate impeller wheels can be produced by stacking one

above the other. This method can increase the efficiency of

impeller production because preparations, such as warming up

the printer, are undertaken once – instead of three separate

times.

In addition to the wheel itself, covers for the impeller

mounting screws (i.e. hub caps) can be manufactured using

AM. Traditionally, hub caps have been fabricated by turning

out cylinders, but the process typically results in as much as

95% of the metal being chipped away and discarded as waste.

With AM, the caps can now be produced with virtually zero

waste.

A design study showed that another benefit of AM could

be a reduction in the overall weight of the impeller by as

90

World Pipelines

/

MARCH 2020

Figure 1.

Additively manufactured radial impeller after overspeed

test.