toll over time, ravaging internal components. All the while,

standards and regulatory requirements surrounding issues such

as fugitive emissions are becoming more stringent.

Change is inevitable

Change-related challenges facing established oil and gas operators

include:

)

New regulations.

)

Decreasing/increasing output – capacity and pressure changes.

)

Emerging technical issues (e.g. caused by degradation/erosion).

)

Changes in the line media chemical make-up (contaminants).

With so many factors at play, there inevitably comes a point

when valves are no longer fit for purpose. However, replacing

them with new products is often too costly and time consuming.

Strategic lifetime extension of existing valves via retrofit solutions

can therefore play an important role here. It enables operators to

meet shifting production demands and avoid unplanned downtime

in a cost-effective manner.

Intelligence-led retrofits

Far from being a stop-gap solution, when a retrofit is handled

well, it can enable an asset to perform better than ever. If control

valves are associated with frequent maintenance, high levels of

manual intervention and undiagnosed problems, it is likely that

they need attention; however, they do not necessarily need to be

replaced. An intelligent retrofit can turn the situation around faster

and more cost-effectively. In a retrofit scenario, valve engineers

have the benefit of insight into real production challenges that

may not have been apparent at the original point of specification.

Moreover, if the valves have been in service for a long time, modern

technologies and manufacturing techniques could offer new ways

to enhance their performance.

A best practice approach

So, what is the best way to go about this? The first step is to

conduct a detailed and purposeful technical review. Naturally,

that requires an inspection of the valves in question, but it is also

useful to consider high-profile valve failures associated with similar

production and performance issues. Drawing on extensive historic

information about original equipment manufacturer (OEM) valve

failures, and wider factors impacting the pipeline, enables engineers

to understand the context of the issues at hand.

Marrying this depth and breadth of technical insight with

advanced valve engineering capabilities can unlock new solutions

to solve enduring and emerging production problems. It results

in retrofit solutions that can improve valve performance and

stand the test of time, positively impacting overall operability and

profitability.

To summarise, a best practice approach to valve retrofits

involves nine critical steps:

)

Inspection and analysis of the valves in question.

)

Assessment of the wider operating environment and

system.

)

Cross referencing historic data on similar OEM valve

failures.

)

Problem solving rooted in the depth and breadth of

dedicated valve engineers’ expertise.

)

Development of highly-engineered solutions that are

precisely tailored to the operating demands and conditions of

valves.

)

Manufacture of new components and integration

with the valve.

)

All relevant testing.

)

Timely supply to the operator.

)

Underwriting and guarantee by an OEM to ensure the

manufactured retrofit reflects full OEM standards.

The following examples show how this works in real-world

scenarios, as handled by Severn.

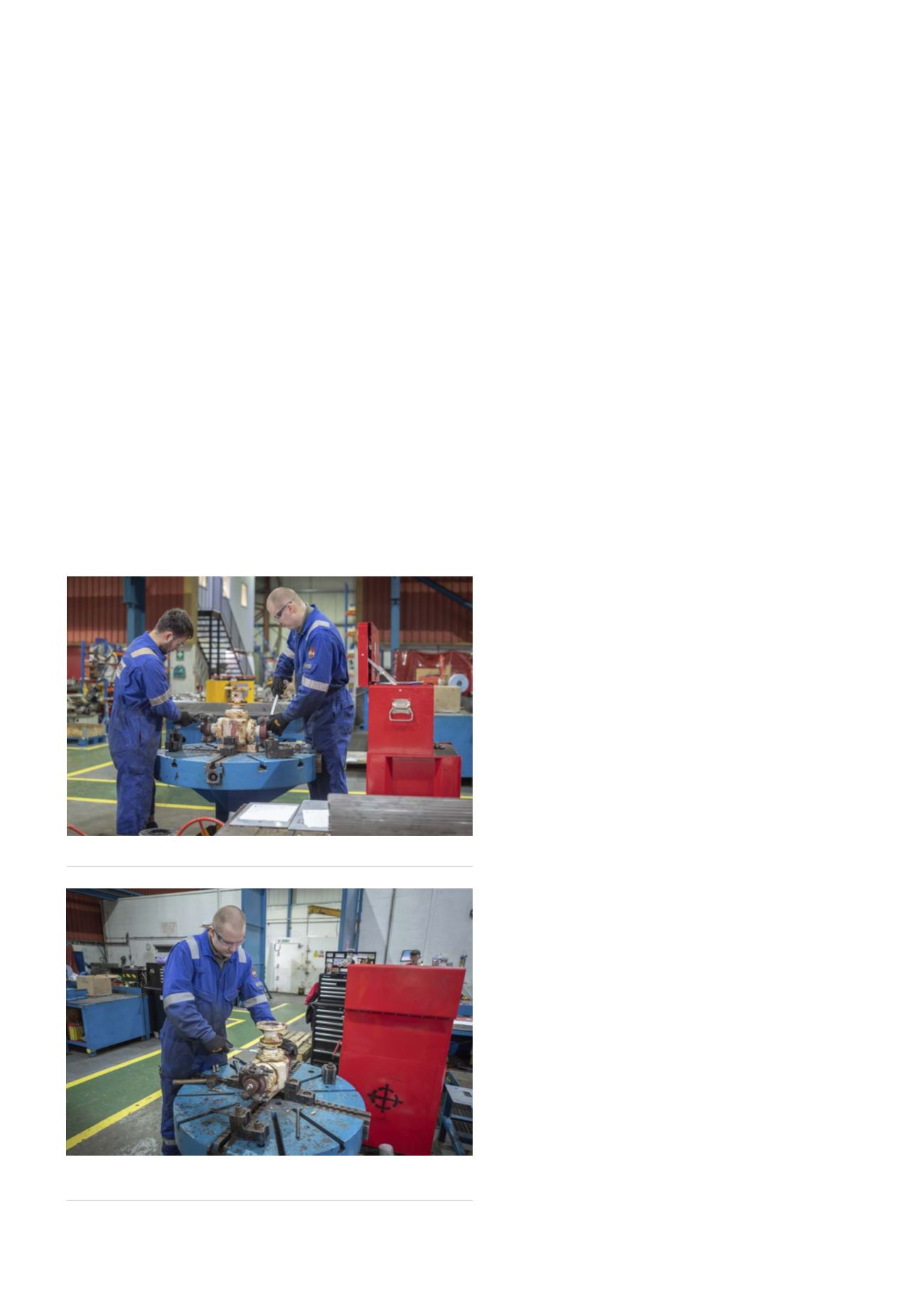

Figure 1.

An initial valve inspection underpins problem solving.

Figure 2.

Specialist valve engineers can improve valve performance

with intelligent retrofits.

86

World Pipelines

/

MARCH 2020