Remote monitoring can also help prevent potentially

dangerous and costly damage to equipment. For example, if a

compressor motor is using more power than usual, an intelligent

drive with embedded Ethernet connectivity can send a signal to

central control. Operators can then remotely stop the motor and

dispatch a maintenance crew to determine the root cause of the

issue.

Security

More connection points mean there are more opportunities

to improve pipeline operations, but they also create new entry

points for cyber threats, resulting in greater security needs.

The US National Institute of Standards and Technology’s

(NIST) ‘Framework for Improving Critical Infrastructure Cyber

Security’ provides guidance for developing a security programme.

Meeting and maintaining the standards of these guidelines

can be broken down into a five-point plan for the security of oil

and gas pipelines and associated critical infrastructure.

)

Requirements development: Create a document that defines

terminology, identifies stakeholders, defines programme

requirements and goals, and assigns roles and responsibilities

for the cyber security programme.

)

Analysis: Conduct an analysis that not only identifies any risks

and threats, but also describes their potential consequences,

severity, and likelihood.

)

Design: Research industry-standard mitigation strategies

and identify the trade-offs, such as the cost, efficiency,

complexity, and impact on operations.

)

Implementation: Create a plan that defines how the

mitigation strategy will be implemented, as well as how

testing, verification, and maintenance activities will be

performed.

)

Educate and improve: Commit to continuous improvement

through ongoing education, training, and auditing.

Taking the next step to a modern pipeline

architecture

The challenge of successfully operating decades-old

infrastructure while meeting today’s business and security

demands can be overwhelming. A partner is needed that can

help deploy modern and smart systems, yet also understands the

pipeline industry and business challenges at play.

Whether a new pipeline is being deployed, or existing

systems are being upgraded, expert help from experienced oil and

gas operatives is vital in order to be sure the right information,

process control, motor control, and safety solutions are being

received for all pipeline infrastructure, compressor and pump

stations, and terminal and storage facilities.

The benefits of a strategic approach to modernisation are

manifold, but operators should be looking to achieve significant

improvements to worker safety and overall cyber security.

Meanwhile, a reduced total cost of ownership, simplified HMI

configurations, improved operability, and reduced downtime and

associated maintenance costs should result in a fast return on

investment for the modernising pipeline operator.

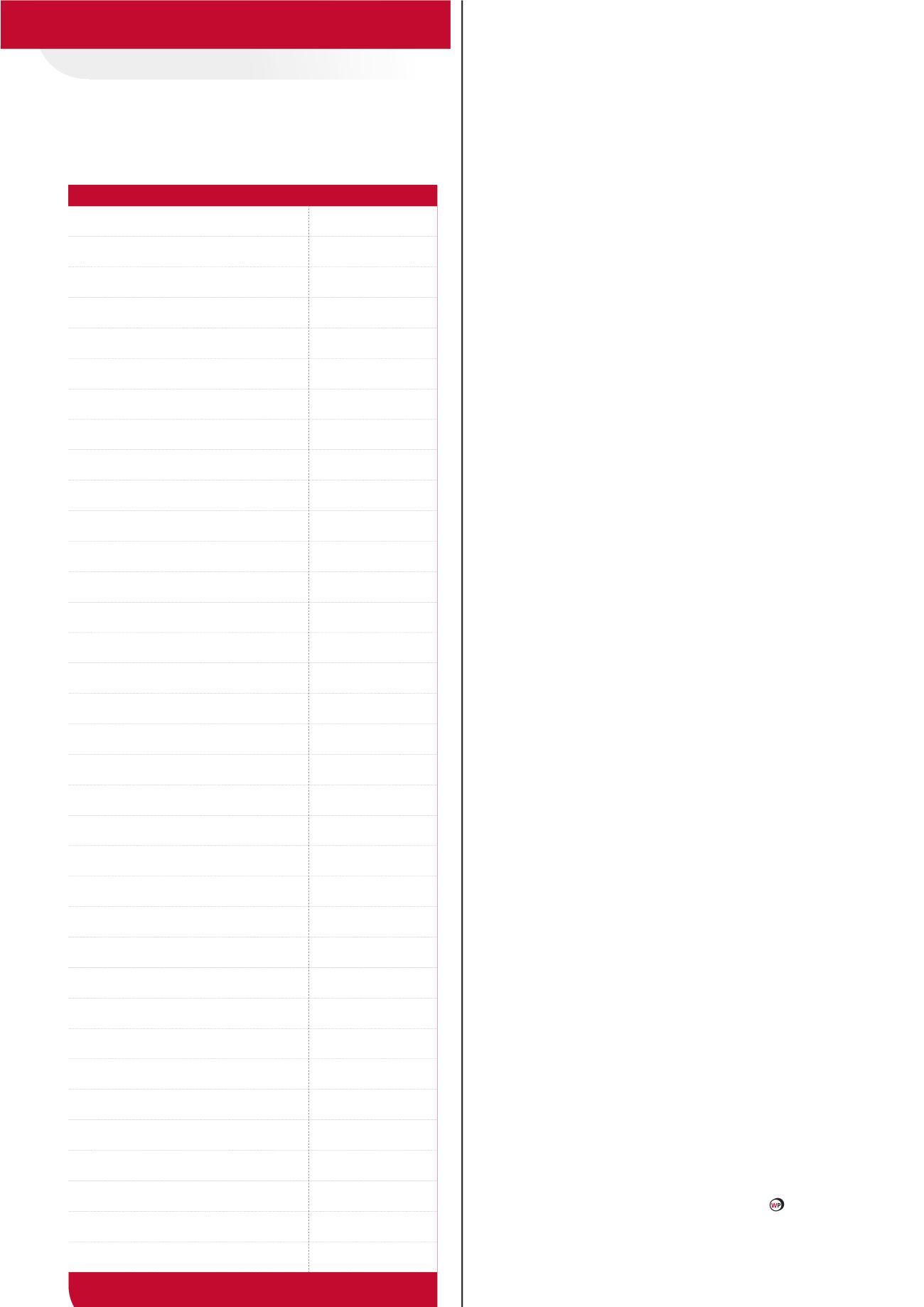

Advertiser

Page

3P Services GmbH & Co.

81

ABC

84

BAUMA

53

Böhmer GmbH

78

CRC-Evans

11

DeFelsko

71

DENSO GmbH

35

Electrochemical Devices, Inc.

77

ENTEGRA

15

Gastech

95

Girard Industries

87

Hercules Piping Tools Engineering BV

47

Intero Integrity B.V.

9

LNG Industry

83

Maats Pipeline Equipment

OFC, 27

Mears Group

71

Midwestern

2

NACE International

73

Pigs Unlimited International, LLC

31

Pipeline Inspection Company Ltd

37

Propipe Limited

91

Quest Integrity

19

ROSEN Group

IFC

SCAIP S.p.A.

OBC

Seal for Life Industries

57

Stanley Inspection

4

T.D. Williamson

25

TOGC 2020

88

TRACTO-TECHNIK GmbH & Co. KG

83

Vacuworx

65

Vermeer

43

Vietz

IBC

Winn & Coales International Ltd

7

World Pipelines

67, 73, 83, 92

Worldwide Machinery

61

ADVERTISERS’

DIRECTORY