integrity assessment tool for regulated pipelines, primarily

utilised for pipelines unable to undergo inline inspection or

be pressure tested.

In simple terms, ECDA is a scientific approach to

evaluate external corrosion threats. It is used to find areas

where corrosion has already taken place, and can also

assist with proactively identifying areas where corrosion

is likely to occur. While this process is generally used for

US regulated pipelines as a means of integrity assessment,

it can also be utilised for unregulated pipelines and other

steel structures. The standard developed by NACE is a

comprehensive process, and when employed on regulated

pipelines should be utilised in its entirety. However, for

unregulated pipelines, the process can be customised to

the specific pipeline or project in question.

The following discusses the ECDA process and how it

can be utilised in an unregulated situation. The four steps

included are pre-assessment, indirect inspection, direct

examination, and post-assessment.

Pre-assessment

Pre-assessments determine the feasibility of the ECDA

process, select the most appropriate indirect inspection

tools, and identify and define ECDA regions. This involves

the following activities:

)

Collecting and analysing current and historical

data pertinent to external corrosion such as pipe

information, construction practices, soil and

environmental conditions, corrosion control practices,

and operational practices and history.

)

Defining and identifying ECDA regions. An ECDA region

is a portion or portions of a pipeline that have similar

characteristics, corrosion histories, and corrosion

probabilities that can be inspected utilising the same

indirect inspection tools.

)

Assessing ECDA feasibility.

)

Selecting indirect inspection tools.

Indirect inspection

Indirect inspections identify and define the severity

of coating faults, identify CP deficiencies, and identify

locations where external corrosion activity may have

occurred or may be occurring.

This is achieved by performing above-grade surveys

on the pipeline in question. The most commonly utilised

surveys include:

)

Coating attenuation survey – alternating current,

current attenuation (ACCA) with depth-of-cover.

)

Coating holiday detection – direct current or

alternating current voltage gradient (DCVG or ACVG).

)

Cathodic protection system performance – interrupted

close interval potential survey (CIS or CIPS).

Survey quality is critical to the success of the project.

Poor quality surveys can miss significant defects or over-

report them, leading to incorrect budget decisions. When

selecting a survey provider, it is important to ask for

examples of previous work and references to make sure

they can provide a quality service.

Aligning the above-grade surveys and taking the pre-

assessment study into consideration would direct the next

phase of the study to specific locations on the pipeline or

asset where corrosion has occurred or may be occurring.

Direct examination

Direct examinations determine which indications are the

most severe and collect data to assess coating damage

and external corrosion activity. Activities include:

)

Prioritising the indications found during the indirect

inspection step.

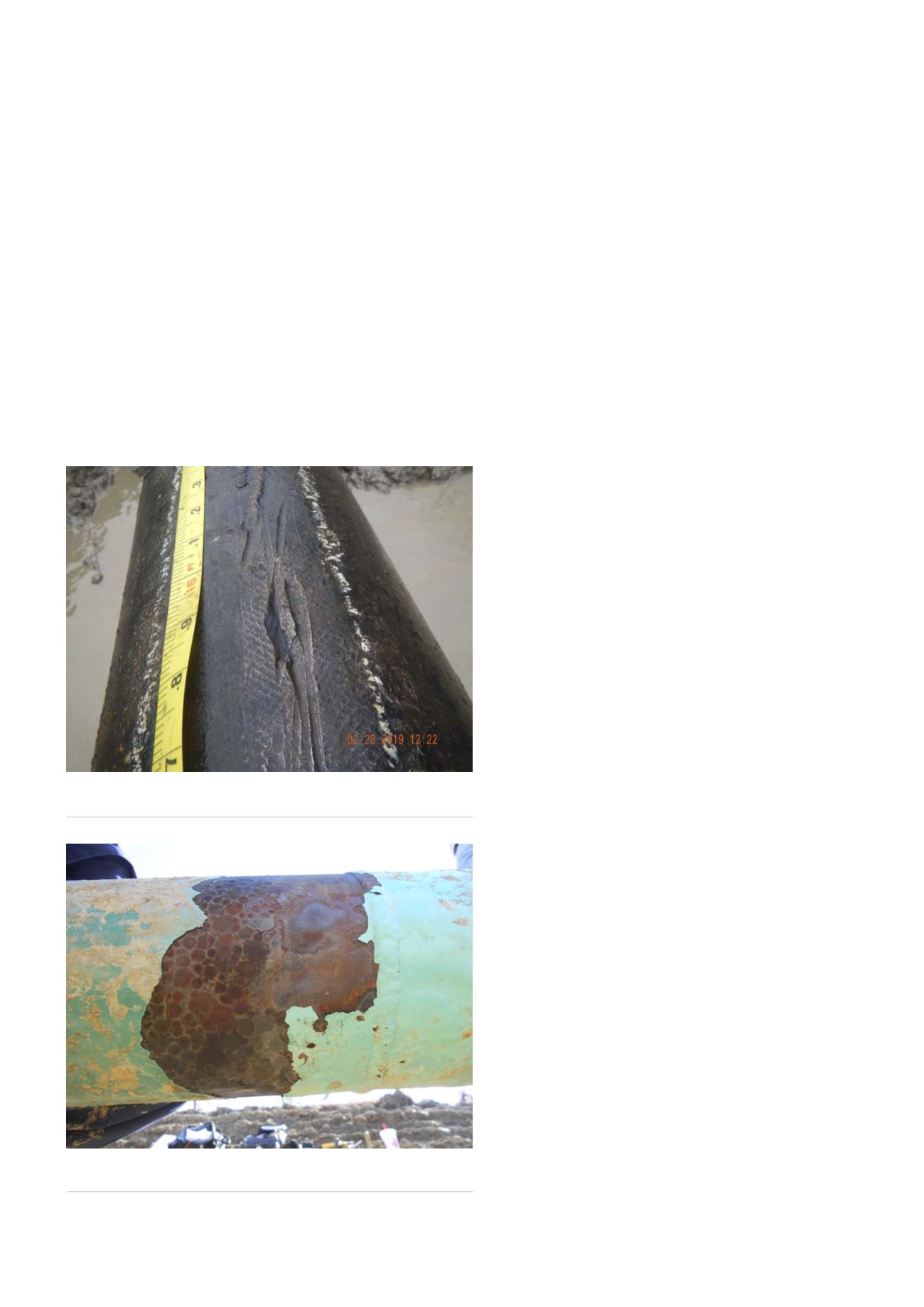

Figure 2.

Coating and corrosion damage on a high-pressure gas

transmission pipeline.

Figure 1.

Third-party damage discovered utilising CIS/DCVG and

excavation.

80

World Pipelines

/

MARCH 2020