focusing method (TFM). As a result of advancements

in software, portability, and battery life, technicians

can bring this computing power virtually anywhere

the work takes them, whether it is at a manufacturing

plant or out in the field.

These instruments and their software are, of

course, only part of an overall phased array UT

solution for internal pipeline inspections.

Corrosion probes

For reliable, accurate C-scan imaging on piping and

other curved parallel-sided surfaces, the preferred

probe has typically been a dual-element transducer

with a roof angle. One element transmits ultrasonic

energy into the surface of the material, while the

other receives energy returning from the bottom

reflection. This pitch-catch technique produces very

little interface echo, which results in better near-

surface resolution, allows the use of higher gain, and

generally allows for more reliable detection and more

accurate thickness measurements compared to pulse-

echo probes.

In many cases pipeline scanning is a manual

procedure, where the only record of the examination

is a report listing the nominal wall thickness and the

minimum thickness measured on locations defined by

a grid. Adjacent areas that may have less overall wall

loss from corrosion can potentially go undocumented,

or result in a sampling of thickness measurements that

is far from being a detailed map of the actual internal

topology of the pipe.

For more critical inspections, automated ultrasonic

testing (AUT) is the typical alternative. AUT combines

a multi-channel UT instrument with a mechanised

position and orientation encoding system, to guide

the scanner over a specific scan path with no manual

manipulation of the probe. This automated approach

can produce rich, detailed inspection data quickly,

with reliable coverage and a high level of repeatability.

However, a conventional automated acquisition

system consists of multiple components: a scanner,

motion controller, couplant feed system, battery

back-up, and extensive cabling.

The necessary hardware can be complicated to set

up and calibrate, pose access limitations in tight or

constricted work areas, and require extra personnel

to use – all of which adds time and cost to the

examination.

New approaches to UT inspections

Suppliers of portable phased array UT instruments

continue to refine their products to take advantage

of greater processing power. However, for pipeline

examinations, two other emerging trends are worth

noting: the development of manual 2D encoded

scanners, and a new non-mechanised encoding system

that uses airborne ultrasound for tracking probe

position and orientation.

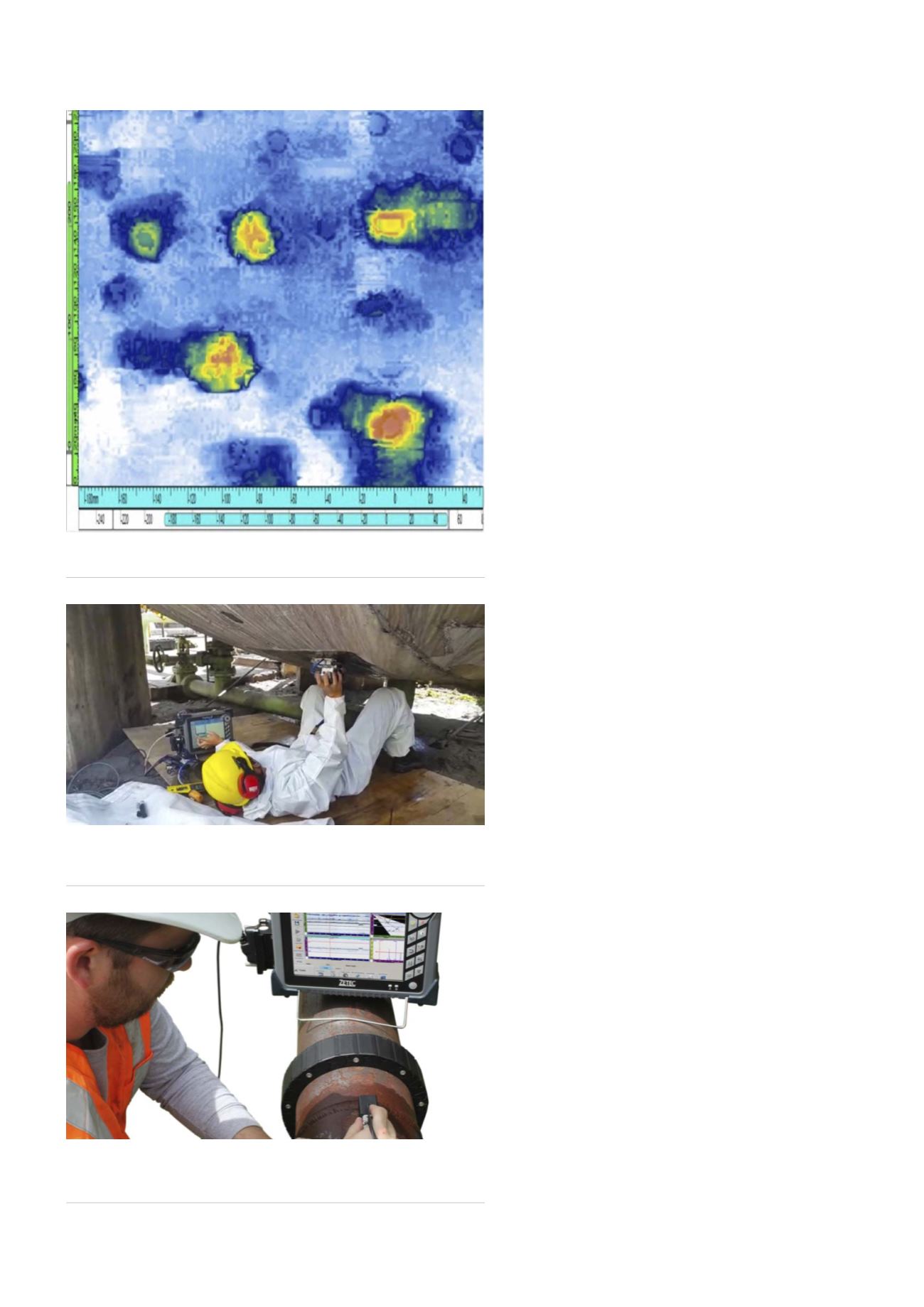

Figure 1.

An example of a thickness map generated using LATITUDE.

Image courtesy of Structural Integrity.

Figure 2.

Manual 2D encoded scanners such as Zetec’s NDT PaintBrush

can work on both flat and curved surfaces. Unlike wheel probes, both

axes are encoded. Image courtesy of Zetec.

Figure 3.

LATITUDE is designed to enable the collection of high-quality

encoded data using a manual examination process. Image courtesy of

Structural Integrity.

76

World Pipelines

/

MARCH 2020