March

2017

HYDROCARBON

ENGINEERING

128

and machining. At least one rupture disc is tested at

room temperature and two rupture discs are tested

at the rated burst temperature.

The outer dimensions (W x D x H) of the test

block are approximately 600 x 600 x 1000 mm. The

time to heat up the rupture disc is about three to

four days. As such, it takes some time to perform

tests at high pressure and high temperature. It is

important to perform tests for HPRDs and it may not

always be enough to extrapolate test results for

lower burst pressures. All influencing parameters

such as material, material thickness, pressure and

temperature, account for the significant differences

between lower and higher burst pressures.

The detailed test setup (Figure 2) illustrates the

placement of the rupture disc as well as the blank

holder and the threaded flange geometry, alongside

the high pressure stud bolts. Two drains are also

presented; one to set the test pressure and another

to install a measurement system to detect the

pressure directly in front of the rupture disc. The

blank holder is installed above the rupture disc unit.

This component is simultaneously used as a blow off

device to relieve the pressure after the rupture disc

opens. In respect to the expected high pressures, a

robust design is necessary to perform safe tests.

The rupture disc unit is installed using a

customised ‘wafer flange’, which is used as a sealing

to increase the pressure up to the defined burst

pressures. Below the rupture disc, a higher volume is

shown to increase the test volume and to ensure a

reliable opening behaviour.

Another challenge is the manufacturing of the

rupture disc. Rupture discs for high pressures are

usually manufactured using housing and a rupture

disc, which is ‘flat welded’ onto the housing

(Figures 3 and 4).

A typical welded design for a standard high

pressure rupture disc with an indicated welding seam

is shown in Figure 4 and a flat plate is welded onto

the housing in Figure 5. Using the standard version,

the weld seam has an influence on the burst pressure.

This leads to another influencing factor besides

material thickness and dome height, which are used

to adjust the burst pressure. The weld seam is a

function of additional parameters that have to be

considered with respect to the burst pressure and

the life time. In Figure 6, a typical rupture disc failure

is presented where the weld seam of the rupture disc

failed. As a result of this, it is important to test the

rupture disc to prohibit an undefined opening, an

undefined burst pressure, and a shortened lifetime.

Solution

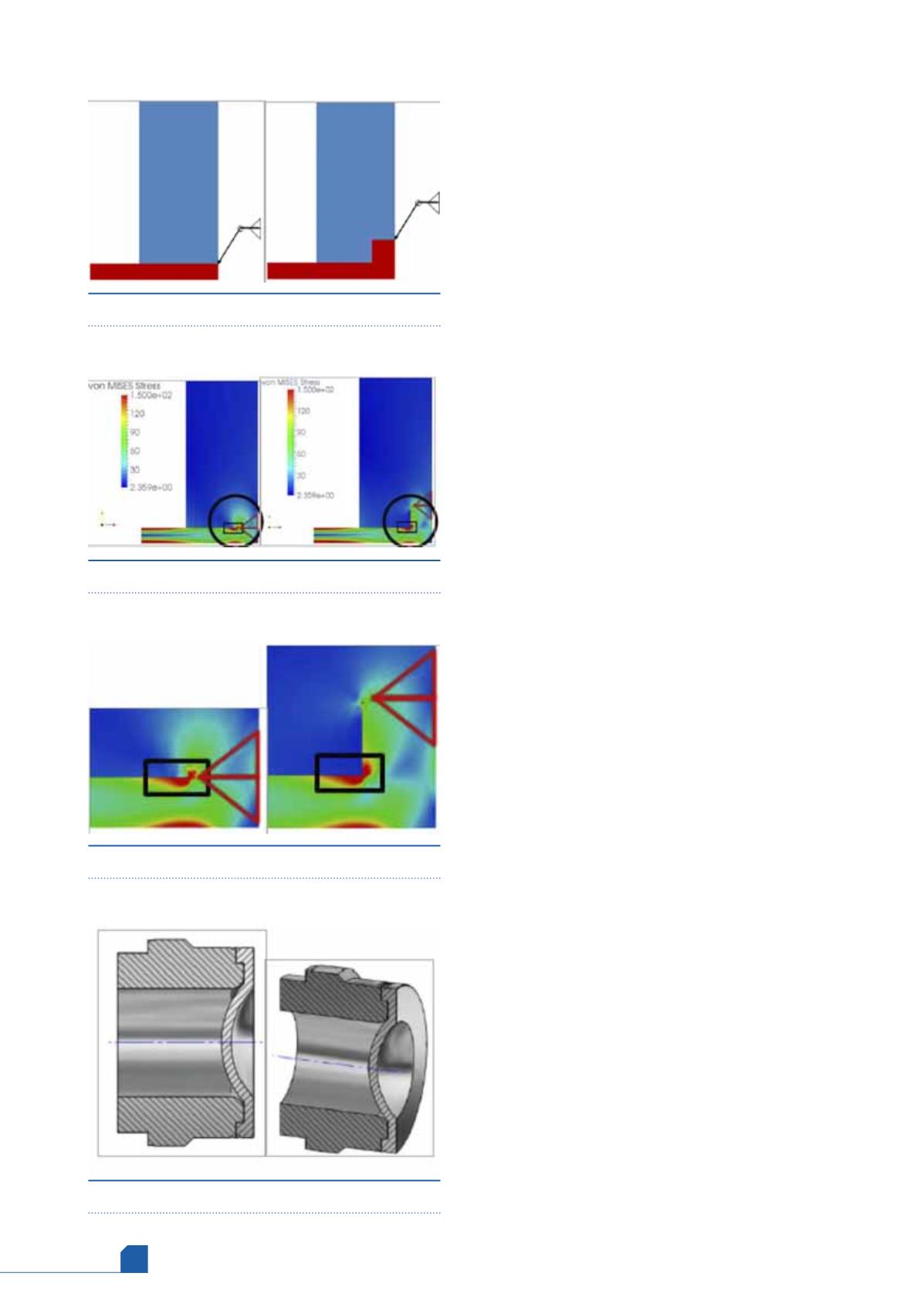

In Figure 7, a schematic model shows the differences

between a standard rupture disc (left) and an

optimised rupture disc (right). A small geometrical

change helps to prevent the welding seam influence

Figure 8.

Rupture disc unit – finite element analysis.

Figure 9.

Rupture disc unit – magnified presentation.

Figure 7.

Rupture disc unit – schematic model.

Figure 10.

Rupture disc unit – longlife version.