March

2017

HYDROCARBON

ENGINEERING

124

The standard differs between conventional

domed rupture discs (forward acting rupture discs),

reverse domed (reverse acting) rupture discs and flat

rupture discs. A rupture disc safety device consists

of a rupture disc and, in the majority of cases, a

rupture disc holder, depending on the rupture disc

type. Due to the wide variety of types, different

assemblies are possible, e.g. safety devices with a

replaceable rupture disc or a welded design with a

non-replaceable disc.

1 - 5

Requirements

Different requirements are considered when

producing a rupture disc. A meaningful solution to

protect the process against overpressure has to be

developed depending on the different types of

rupture discs as well as the customer requirements.

A typical design for a pressure above 200 barg is a

forward acting rupture disc. Two key factors have to

be considered with respect to rupture disc

configuration: burst pressure and burst temperature.

Depending on the specified material and its

behaviour at different temperatures, the burst

behaviour can change depending on temperatures.

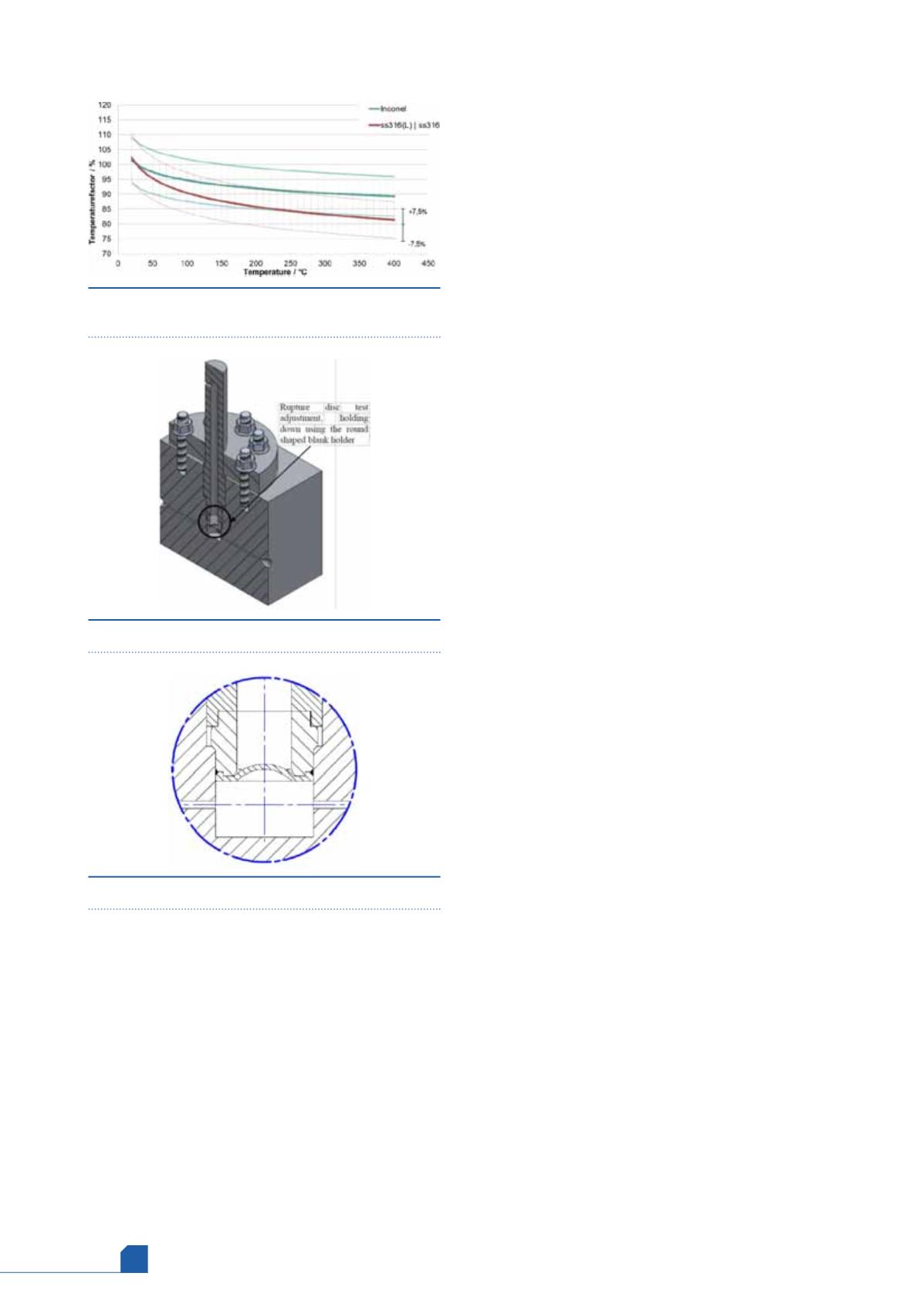

Figure 1 shows the difference between stainless steel

(ss316(L)) and Inconel. The temperature factor for

stainless steel decreases rapidly, whereas the

temperature factor for Inconel is more constant. The

given values are the original tested temperature

factors for a reverse acting buckling pin rupture disc

within a total duration of five and a half years (all

rupture discs manufactured and tested between

January 2010 and June 2015). Furthermore, these

temperature factors are independent from different

material batches and nominal sizes, which results in

an overall deviation of

±

7.5%. The overall quantity

for these tests is >500 pieces.

For high pressure rupture discs (HPRD), an

appropriate graph is not available. However, Inconel

is a typical choice for processes where higher

temperatures and higher temperature ranges are

needed.

Furthermore, high burst pressures require a

robust design. The housing is a pressure-containing

part and has to withstand high loads. The rupture

disc itself must be robust against the high working

pressures of the process, but at the same time the

rupture disc has to be sensitive enough for a reliable

response if needed. Typically, the burst tolerance is

determined to

±

3% and better for high pressure

processes. Intensive testing is required to verify a

rupture disc for high performances. The burst

testing, in general, is described in EN ISO 4126-2.

Depending on the temperature, as well as the total

quantity of an order, different quantities have to be

tested.

4

For a HPRD, tests have to be performed in

respect to high pressures and high temperatures. A

batch of approximately 15 – 20 rupture discs are

used for testing. These tests are performed to verify

the rupture disc as well as the rupture disc housing.

Usually, all tests are performed in collaboration with

the respective customer. In this article, the general

tests are described to certify that the rupture disc is

a suitable solution to protect LDPE processes against

inadmissible pressure.

As described previously, a forward acting rupture

disc is used as a basic model. Therefore, it is

necessary to manufacture a domed (pre-bulged)

rupture disc and a suitable housing. The material

quality also has to be considered due to the welding

design. The welded assembly must be suitable for

high pressure flange connections. The connection

itself depends on the respective flange connection

Figure 1.

Temperature factor for different

temperatures.

Figure 2.

Detailed test setup.

Figure 3.

Improved solution of a rupture disc unit.