March

2017

HYDROCARBON

ENGINEERING

132

Chemical additives.

Polynuclear aromatics.

Sulfur.

Used oil disposal

There are several ways to dispose of used oil. A significant

amount is improperly disposed of by dumping it into the

ground, sewer, or waste. However, many regions have made it

illegal to dispose of used oil improperly. This is because when

used oil is disposed of without any treatment, the toxic

substances within it will contaminate rivers, groundwater and

soil. More importantly, many of these toxic chemicals are

carcinogenic and can cause serious health issues.

Used oil is also commonly used as fuel in boilers and

furnaces, which, since used oil is mostly composed of

hydrocarbons, means it is high in energy density. Each gallon can

produce approximately 41.4 MJ/kg,

1

therefore, burning used oil

is considered more economical and energetically beneficial

than disposing of it. However, when used oil is burned it

produces carcinogenic material, metal organics, acid halides,

particulates, sulfur oxides and nitrogen oxides, which are

released into the atmosphere. Table 1 is a list of substances and

their designations when used oil is burned in furnaces. The data

from Table 1 assumes that a space heater is used. In general,

space heaters are not equipped with waste gas controls,

therefore heavy metals can escape into the atmosphere. It is

possible to use pre-treatment techniques to filter out some of

the heavy metals and neutralise some toxic substances before

burning the used oil, however, the effectiveness of

pre-treatment is far from ideal. All of the substances in Table 1

are toxic to humans and can cause serious health conditions, if

excessive amounts are released. For example, lead, cadmium

and chromium are carcinogenic materials.

Moreover, SO

X

in the atmosphere is a precursor to acid rain.

The ash leftover from burning is highly concentrated in heavy

metals and toxic substances. In most cases, the ashes are

disposed of in the trash or onto soil, meaning the

environmentally damaging components will be dispersed and

potentially contaminate the soil and underground water.

Some industrial furnaces are equipped with waste gas

controls to prevent excessive heavy metals from entering the air.

However, even with the waste gas treatment, other substances

such as PO

X

, SO

X

, NO

X

, and HCl are still released.

Recycling/re-refining used oil

Recycling and re-using a resource is always a more sustainable

alternative to dumping, disposing or burning. Clean and

re-usable base oil can be extracted from used oil and

categorised (Table 2).

The following are the recycle/re-refining technologies

available today:

Acid clay treatment.

Vacuum distillation.

Clay treatment.

Solvent extraction.

Hydrotreating.

Acid clay treatment is an older technology that removes

contaminants and produces Group I base oil that can be

re-used in lower grade lubricant applications. This process has

Table 1.

Various substances' designation when

used oil is burned without waste gas treatment

2

Substance Designation when burning used oil in space

heaters

Lead

>50% to air, balance to deposits

Cadmium >50% to air, balance to deposits

Chromium <50% to air, balance to deposits

Zinc

Approximately 50% to air, balance to deposits

Sulfur

SO

X

to air

Nitrogen

NO

X

to air

Polynuclear

hydrocarbon

CO

X

to air

Chlorinated

hydrocarbons

HCl to air

Phosphorous PO

X

to air

Phenols

CO

X

to air

Waste

streams

Ash deposits

Notes: SO

X

= sulfur oxides, NO

X

= nitrogen oxides,

HCl = hydrogen chloride, PO

X

= phosphorous oxides,

CO

X

= carbon oxides.

Table 2.

Mineral oil-based base oil specifications

Sulfur

Saturates Viscosity index

Group I

>300ppm ≤90% 80 – 120

Group II

≤300 ppm ≥90% 80 – 120

Group III ≤300 ppm ≥90% ≥120

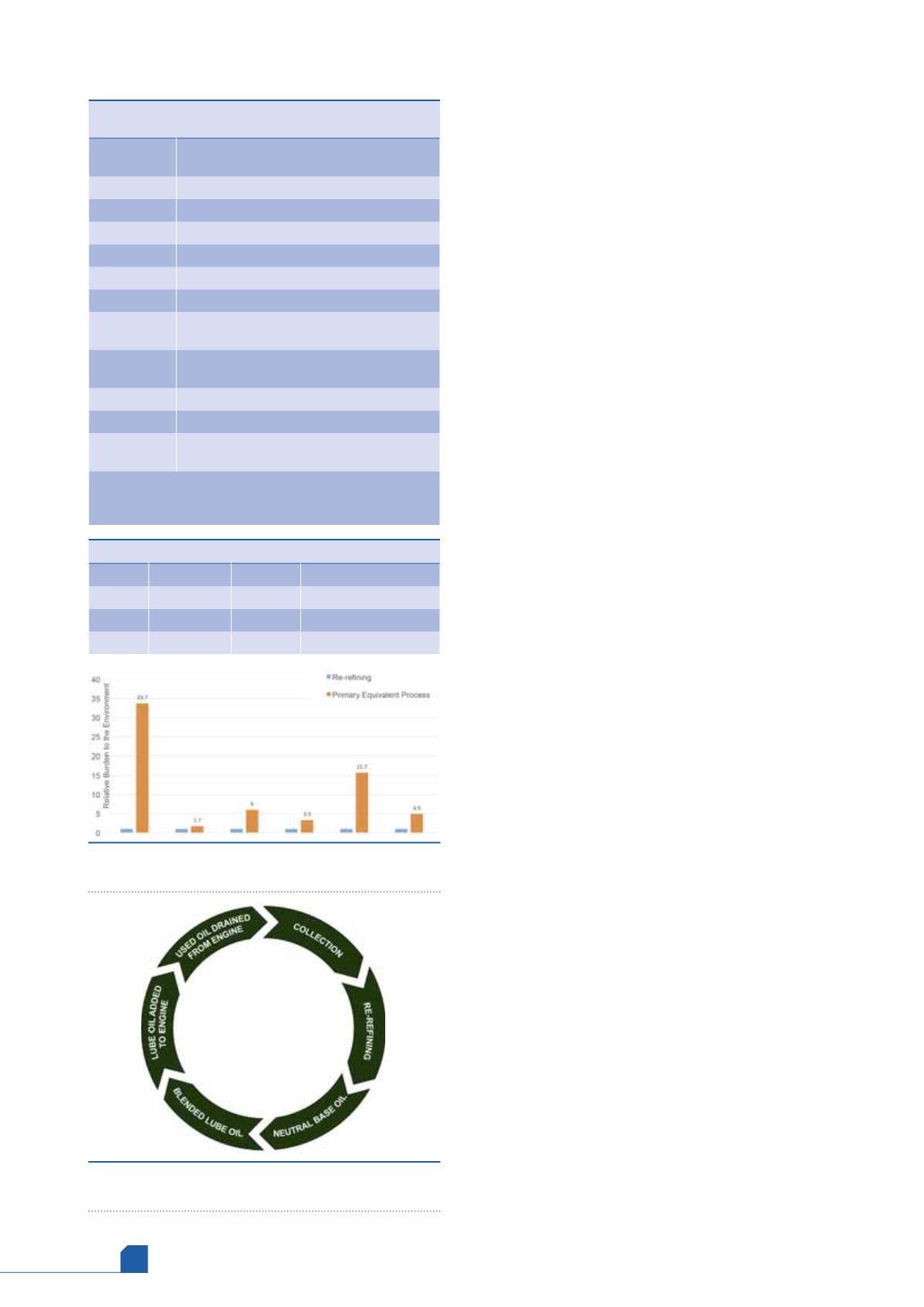

Figure 1.

Relative burden to environment between

re-refining and crude refining.

3

Figure 2.

Closed loop collection and re-refining of

used oil.