March

2017

HYDROCARBON

ENGINEERING

108

How are governments tackling safety?

Governments work with operators and contractors to

ensure the industry remains as safe as possible. Regulations

are frequently updated and industry stakeholders in the UK

and abroad collaborate to ensure the requirements set out

by the Health and Safety Executive are met. Early in 2016,

the UK government pledged £20 million to innovation in

the north east of Scotland. Amongst other things, this

investment is evidence of a commitment to develop skills

and technology within the oil and gas industry that

augment the existing safety framework. Innovate UK also

launched an Energy Game Changer initiative, which made

£1.5 million available to innovators outside the energy

sector. This is to encourage the development of radical

thinking and new technologies to help resolve and monitor

health and safety challenges facing the industry.

Outside the UK, other oil and gas economies have set

safety high on the agenda. For instance, the Saudi Ministry

of Labour (MOL) conducted 142 600 site inspections from

2015 to 2016, maintaining a strict process of fining based on

violations. This helps to improve health and safety

practices, not only in oil and gas but also throughout the

wider economy. The Saudi government is also encouraging

foreign health and safety specialists to showcase products

that enhance safety at various local events for the eventual

implementation in the country, However, not all safety

enhancement is led by government or regulation,

particularly where safety benefits also drive economic,

productivity and efficiency gains.

In the US, there are over 6000 independent companies

working to find and deliver oil and gas, more than any

other country in the world. Market forces serve to spark

innovation, as companies fight for the competitive edge.

The market participants that focus on health and safety as

a differentiator drive messages across the sector, informing

the industry of the benefits of putting safety first and

innovating to gain market share.

What innovative solutions can help?

During an uncertain time in the oil and gas industry, the

additional cost and resources needed to address

regulations means it is becoming harder for health and

safety requirements to be met. Cost cutting may

inadvertently encourage companies to cut corners. So, at

what point does the balance sheet come at the expense of

welfare and safety? Health and safety innovations can assist

in helping organisations meet regulations in a cost efficient

way. However, changing attitudes towards investing in

innovation as a long-term cost saving measure, rather than

a short-term expense, remains challenging.

New innovations are being introduced to the industry

almost daily, from drones being used as an early detection

system to carry out live asset inspections and assess any

maintenance requirements, to using wearable technology

to keep track of personnel in the field, to the use of apps

to maximise all areas of safety and monitoring. Cross

industry knowledge sharing is vital to ensure continued

success in using technological innovations to improve

safety. In addition to the safety benefits of new innovation,

there are also considerable monetary and operational

efficiencies that can be achieved.

Deploying innovation

Ageing assets are a major source of concern when it comes

to health and safety. Current industry pressures have the

potential to lead to delay of required maintenance works,

which can have adverse effects on health and safety.

However, investing in innovative solutions can lead to

improvements in health and safety, improved productivity

and can have a positive impact on economic output.

One solution to conducting hot work in zoned areas

offered to the oil and gas industry is the Safehouse habitat.

The habitat is a modular, flexible enclosure, which is over

pressurised to approximately 50 Pa to ensure that there is no

ingress of hazardous gases to where the hot work is being

conducted. Air is drawn into the habitat from a safe area via a

fan, which ensures a minimum of five air changes per hour to

create a safe and comfortable atmosphere for those working

within the habitat. The company's gas sensing module (GSM)

detects 10% lower explosive limit (LEL) of methane as well as

all other hydrocarbons and noxious gases. The toxic alarm will

be activated at 5 ppm for H

2

S, as per the EH40/2005 work

place exposure limits regulation. When a welding control

module (WCM) is introduced as part of the system, the alarm

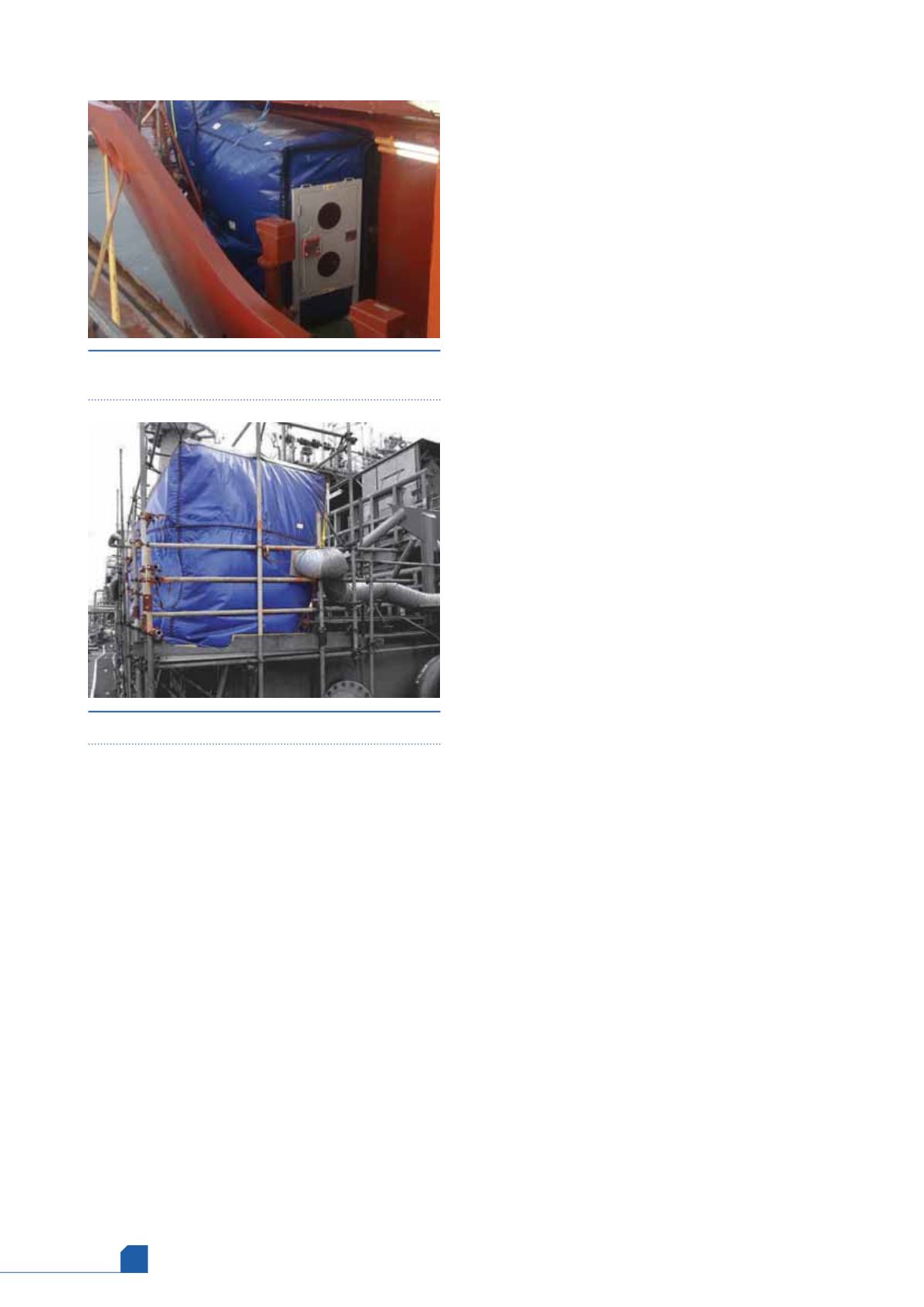

Figure 1.

Habitat on-board LPG tanker to allow

emergency repairs.

Figure 2.

Habitat in-situ offshore.