March

2017

HYDROCARBON

ENGINEERING

30

refinery operator assembles the right team for this

phase and that the team can provide all the

necessary skills. Experienced partners, such as

licensors, project management consultants, front

end engineering design (FEED) contractors,

engineering, procurement and construction (EPC)

contractors, and joint venture partners, will be

essential to the success of the project.

Every project presents different challenges and

opportunities. Operators must select and adapt the

process that best fits their company’s culture,

internal capabilities, decision and approval

processes, in-country resources and technical skills.

The goal of accelerated project delivery is only

achieved by examining, challenging and improving

the processes and habits that are the norm within a

company.

Swift progress from concept to startup requires

clear expectations, an efficient execution plan and

the selection of reliable technology that will deliver

what is needed on time and on budget. One of the

most effective ways to achieve this is to encourage

close collaboration between the refinery team and

the service suppliers with agreed and aligned goals.

This approach has repeatedly been shown to deliver

the best project startups. The startup method

offered by Shell Global Solutions can have a

positive influence on project profitability and

payback time for investors.

Adopting global best practices

helps operators to achieve

efficient commissioning and

successful startup, and can

deliver multi-million dollar

savings.

Operation: achieving

and sustaining

operational

excellence

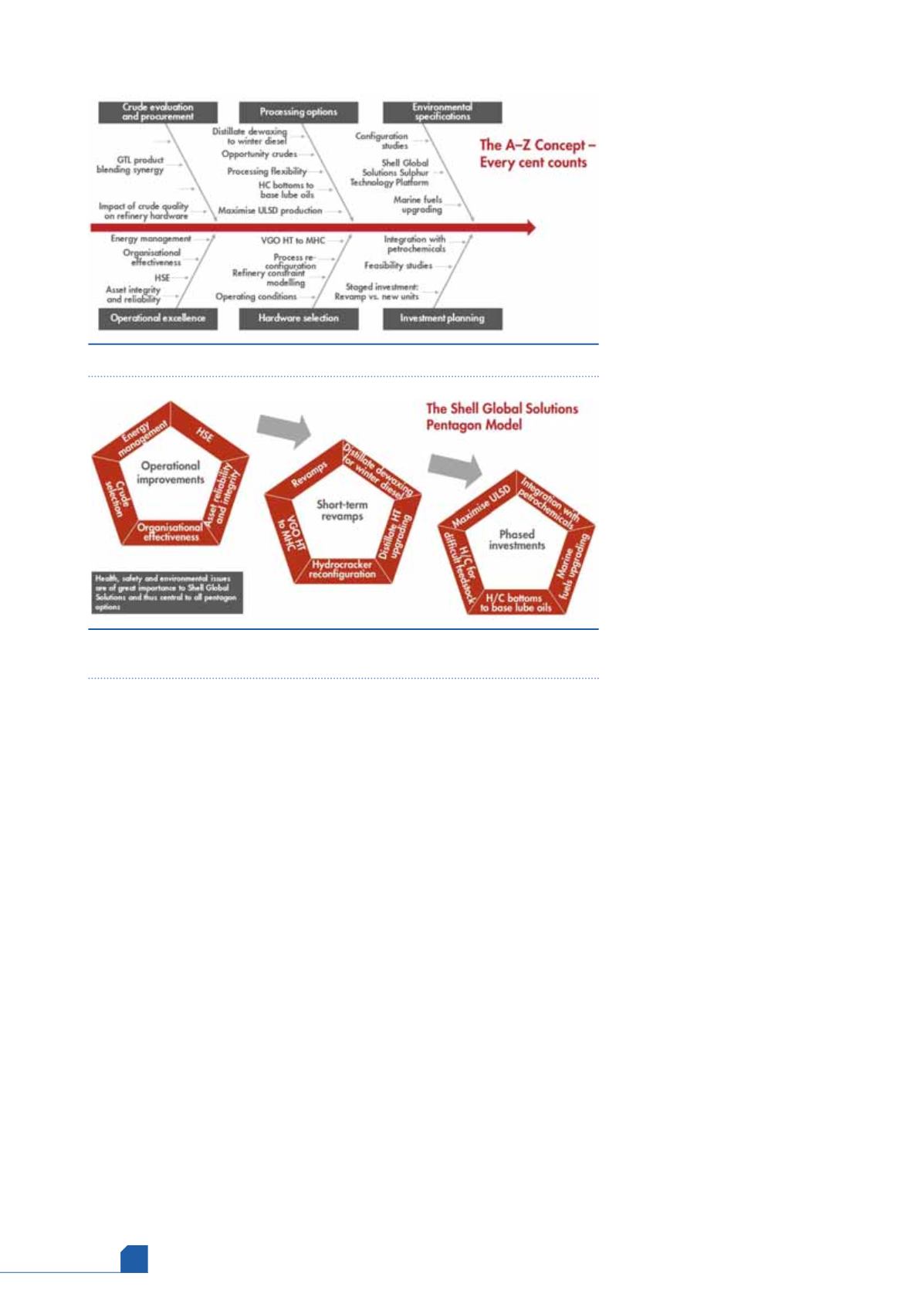

The A – Z Concept used by

Shell Global Solutions (Figure 3)

shows that there is scope for

refiners to make improvements

right across the value chain,

from crude selection studies

that can introduce a lower cost

crude diet, to more complex

projects such as adding

dewaxing capabilities; feeding

hydrocrackers with alternative

feedstock blends using deep

flash distillation capabilities;

solvent deasphalting products

(demetallised oils); or

integration with

petrochemicals.

There are many options for

operators when it comes to

adjusting how their refinery

complex runs. High levels of reliability deliver strong

margins, but operators can also make efforts to

reduce operational expenditure and to introduce

new opportunities. These will involve decisions

about which crude to process and the value of

adding complexity compared with upgrading existing

hardware through a revamp.

Strong leadership will keep a refinery

competitive while market conditions change and

new opportunities emerge. The Shell Global

Solutions Pentagon model (Figure 4) provides a

roadmap for implementing the A – Z projects and

enhancing competitiveness.

The Pentagon model focuses on implementation

in three key areas: operational improvements,

short-term revamps and phased investments.

The first step in the Pentagon diagram

encourages operational improvements such as

reliability and energy management projects that

require small capital investments to maximise value

from the existing assets. For this step, Shell Global

Solutions has seen improvements ranging from

US$0.1 to 1/bbl. The next step is to consider how

revamps could help to generate increased value.

Revamps can offer substantial gains for relatively

modest investments, and the returns from these can

help to fund any larger capital projects that the

operator is planning as part of a phased investment.

Figure 3.

Options for refinery improvements across the value chain.

Figure 4.

Areas where refinery operators must display leadership and

foresight in order to enhance competitiveness and profitability.