March

2017

HYDROCARBON

ENGINEERING

28

facing tough challenges as they search for

opportunities that will help to ensure profitability.

The situation for each refiner extends beyond local

market conditions and involves geopolitical and

macroeconomic influences that are not easy to

counter.

The power of continuous

improvement

Continuous improvement requires constant effort to

improve products, services or processes. The

approach covers both incremental and breakthrough

improvements that are designed to deliver significant

value in one step. All the refining industry’s top

performers are committed to continuous

improvement strategies. These strategies involve

investing in and optimising new projects, and,

crucially, having a steady pipeline of new projects to

develop.

The refinery operators that achieve the highest

performance all take a similar approach to delivering

and optimising their projects. They have processes

that enable continuous planning of new projects and

rapid execution of the selected

projects, and have a willingness

to optimise and adjust

operations after startup.

But that is only part of the

story. The key to continuing

success for leading refiners is

not to stand still. Once a project

has been through the

plan-execute-operate phases,

these operators will repeat the

process on the next project

(Figure 2). This is the crucial

aspect of continuous

improvement. The first step

towards achieving this is to

examine the key elements of the

plan-execute-operate cycle in more detail.

Planning: the quest for reliable, value

adding investments

Effective planning is the foundation for successful

and sustainable projects. Selecting the right skills and

finding the best support during the planning phase

are vitally important for refinery operators. Major

projects can take years to complete and are delivered

against an ever changing backdrop of geopolitical

and macroeconomic conditions. Refiners want to be

certain that their plan, and its configuration, will

prove to be the most effective option and that the

economic case for development is robust.

They must address some fundamental business

questions. How can they build in flexibility to meet

changing market conditions? What is the potential of

the refinery to accommodate opportunities such as

expansion to include petrochemical operations or

increased conversion flexibility? Defining short and

long-term strategies requires input from a competent

and experienced planner and a skilled workforce that

understands how to execute projects. Shell Global

Solutions works closely with refiners and challenges

the criteria that are set during the technology

selection phase. This approach helps operators to

avoid regret investments.

Selecting the refinery configuration is one of the

most difficult tasks that operators face during the

planning phase. To maximise the value of these

multi-billion dollar investments, operators must set

clear goals for the refinery and seek impartial advice

from experienced consultants who can help them to

define the ‘best’ configuration for operations in a

highly competitive market. It is always wise to

consider multiple future scenarios and to determine

whether the selected configuration could cope with

these potential scenarios.

Execution: finding the shortest route

from concept to startup

After careful and effective planning, the execution

phase can begin. As before, it is crucial that the

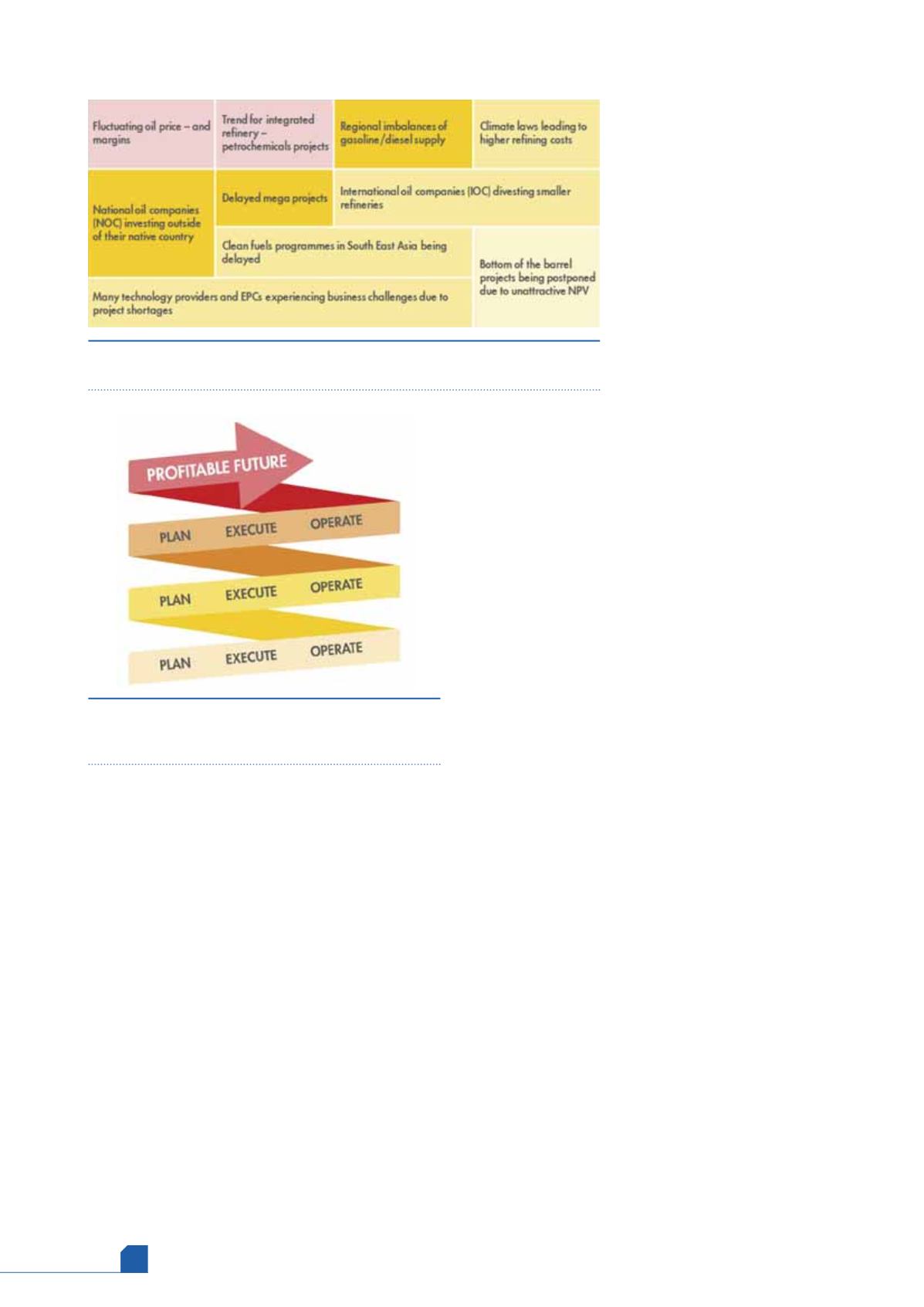

Figure 1.

Challenges, delays and postponements are common features of

today’s refining sector.

Figure 2.

Repeating the plan-execute-operate process

enables refiners to achieve a continuous improvement

cycle and leads to sustained profitability.