March

2017

HYDROCARBON

ENGINEERING

142

During an inspection phase, a nozzle connection to a critical

item of equipment (shell and tube heat exchanger) was found

to be corroded. The plant owners were concerned that the

remaining thickness, required to safely retain the fluid during

operation, was non-compliant with the site schedules and

safety standards.

The owner operator wanted to avoid replacing the nozzle as

this could be time consuming and potentially costly due to the

necessary system downtime. To avoid a plant outage, On Line

Design & Engineering needed to implement a fitness for service

solution that enabled the heat exchanger and piping to safely

remain in operation.

The challenge

Intergraph CAESAR II® pipe stress analysis software was used to

create a model of the entire piping system, including a

connection from a tower to the heat exchanger nozzle. The

main objective was to avoid any costly shutdowns and to have

a better understanding of the current state of the piping

system.

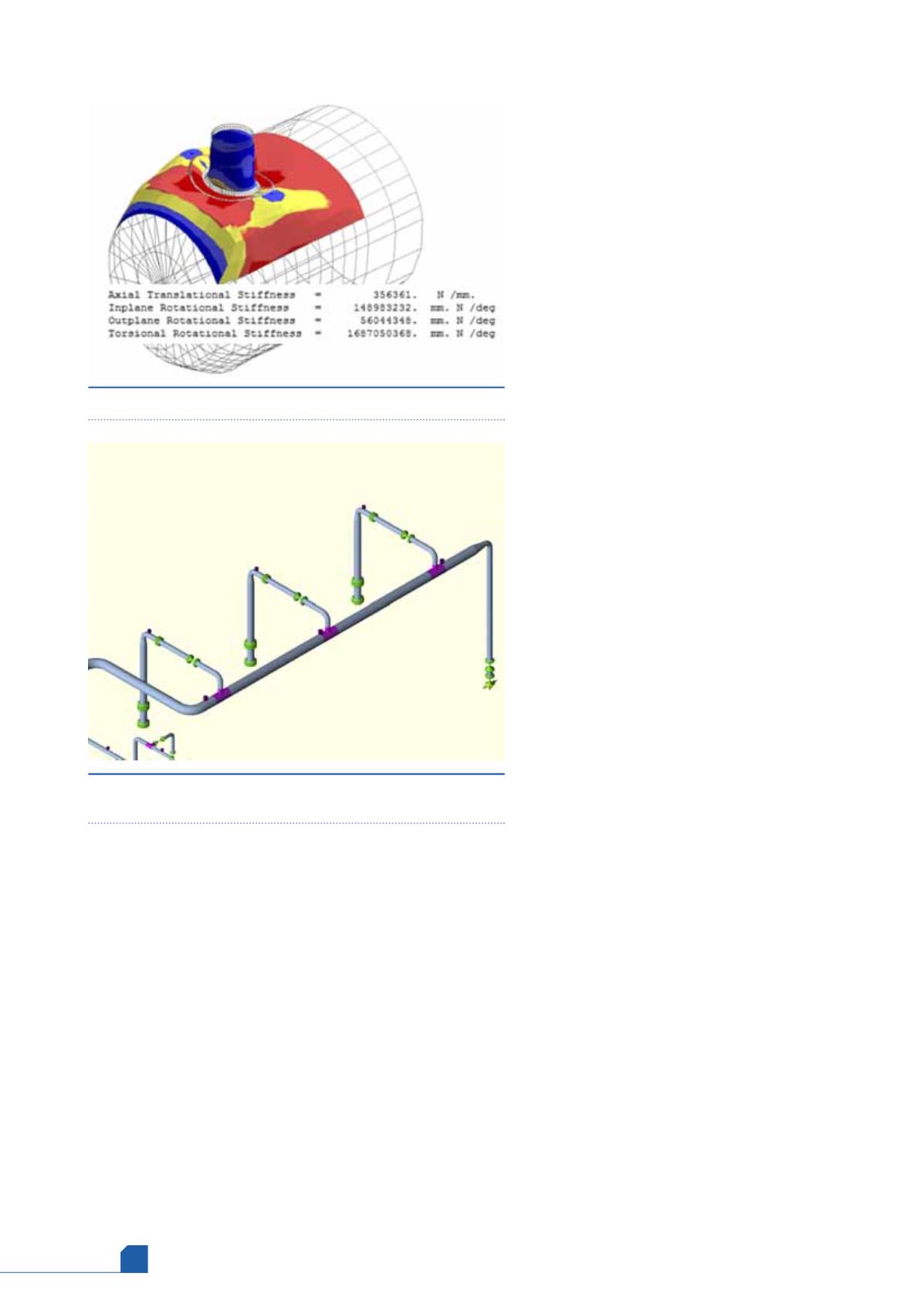

Figure 2.

An example of the three boiler connections that were

included.

Figure 1.

A variety of stiffness values were calculated.

Initial modelling and analysis combined with

a site inspection proved the whole system to be

sensitive to the stiffness values of nozzle

connections and certain pipe supports. The

challenge was to accurately calculate the

stiffnesses of critical components at, and close

to, the nozzle. This was most significant when

calculating accurate loads and stresses.

The solution

On Line Design & Engineering implemented

CAESAR II for qualification of piping systems in

accordance with appropriate design codes to

ensure compliance with site and industry

standards. Paulin Research Group NozzlePRO

TM

software supplemented the solution by carrying

out local finite element analysis (FEA) on pipe

components, including on the pipe checks.

Using the software, On Line Design &

Engineering found that the piping system in

question was safe since the loads produced on

the equipment nozzle using the more refined and

accurate model were lower than the owner

operator originally believed.

The analysis showed that the nozzle

connection was still compliant with site and

industry standards, enabling the owner operator

to avoid an unnecessary nozzle exchange and an

unproductive and lengthy shutdown of the

system.

The future

Prior to using CAESAR II and NozzlePRO, On Line

Design & Engineering outsourced such complex

engineering projects to other third-party

organisations because the tasks require a high

degree of accuracy and speed of analysis.

Outsourcing was not only more expensive, but it

also meant that control over project timescales

and completion was more difficult. Plus, it

prevented the development of engineering

expertise, a vital component in selling its services.

The successful implementation of the

software on this project provided the company

with expertise to expand its solution offerings to

similar in-depth projects in the future. The

company is planning to further train its

employees in Intergraph solutions and has

already invested in Paulin Research Group

FEATools' FEA software to further facilitate more

accurate analysis. The aim is to prevent

unnecessary piping system modifications while

ensuring compliance with site and national

standards.

Case study 2: NEWES

Background

NEWES is one of the largest maintenance and

service companies for the steam boiler industry