March

2017

HYDROCARBON

ENGINEERING

139

level’ and ‘total station’ methods. Furthermore, a

bottom edge differential settlement allows scanning

from within the tank, determining localised movement

of the tank floor plate. Internal structural data,

including floating roof drainage lines, etc., can also be

scanned and presented separately to clients.

Case study

A leading storage terminal based in the UK has

implemented 3D laser scanning. It has helped to save

the operators time previously spent on draughting

plant layouts and piping and instrumentation

diagrams/drawings (P&IDs). It has also eliminated the

time involved in the logistics of getting to and from

the process plant and conducting comprehensive

surveys. The technology provides quick reference

whilst discussing issues that need to be addressed

within the plant, generally eliminating the need to visit

the location in question. Other additional benefits of

the technology that have yet to be exploited at the

terminal include training and presentations. However, a

representative at the terminal mentioned that 3D laser

scanning does not always totally negate the need to

physically visit the plant.

The potential for 3D video fly-throughs – or

drones – to be used as a commercial tool was further

highlighted by the terminal’s commercial team, who

complimented the technology’s effectiveness as a

visual aid during technical presentations to clients and

in training programmes for personnel.

Over the last 18 months, ALS provided 3D laser

scanning services to terminals and industrial facilities

across the UK, including several recent projects for

terminals and refineries. There has also been a growing

appreciation of the benefits that 3D laser scanning

technology can bring to the oil products sector,

particularly with regards to applications for pipework

modelling and storage tank analysis. ALS’ ability to

prepare an inexpensive and detailed ‘in-service’ health

check on customers’ tanks enables a company to make

an informed decision on where they should be

concentrating their inspection budget on localised

material thickness analysis. The rate at which tank 3D

laser scanning can be achieved ensures that the study

can be completed before any influencing factors are

allowed to change, such as temperature or tank

contents. The final reports are versatile in terms of

how they can be utilised by a company, including

assisting in company compliance with industry and

government standards and regulations.

Ongoing projects

In an ongoing project for a major UK oil refinery, ALS is

providing its 3D laser scanning service in support of the

client’s inspection programme for API 653, and its

control of major accident hazards (COMAH) legislation

compliance. The company has been commissioned to

scan 120 storage tanks, assessing tank settlement, tank

shell verticality at selected points (determined by

Engineering Equipment and Materials Users Association

[EEMUA] guidelines), shell plate radial deflection and

tank settlement. Scan files will also be used to

calculate bund volumes.

Developments

ALS is now able to assess the differential settlements

between the tank and its connected piping where

additional bending moments and loads, which were not

considered in the original design, are imparted. This is

achieved by performing several annular plate scans at a

close distance. It also requires the company conducting

the scan to employ the use of pipework modelling

techniques on local lines. The resulting modelled

pipework is offered for structural analysis, this is in

order to decide where additional support or, indeed,

expansion joints or bellows are necessary. This means

that, cumulatively, the team is now able to scan

approximately 96% of the average storage tank.

Conclusion

Laser scanning is now proven to be a trusted source of

data collection within the oil and gas industry. With the

high accuracy of data available, ALS has noticed a large

shift in client expectations and a strong demand for its

services as a cost effective solution for collecting

analytical data from the site. With the auxiliary services

such as tank calibration available, the saving on cost is

further increased in comparison to traditional methods

of analysing tank terminal assets.

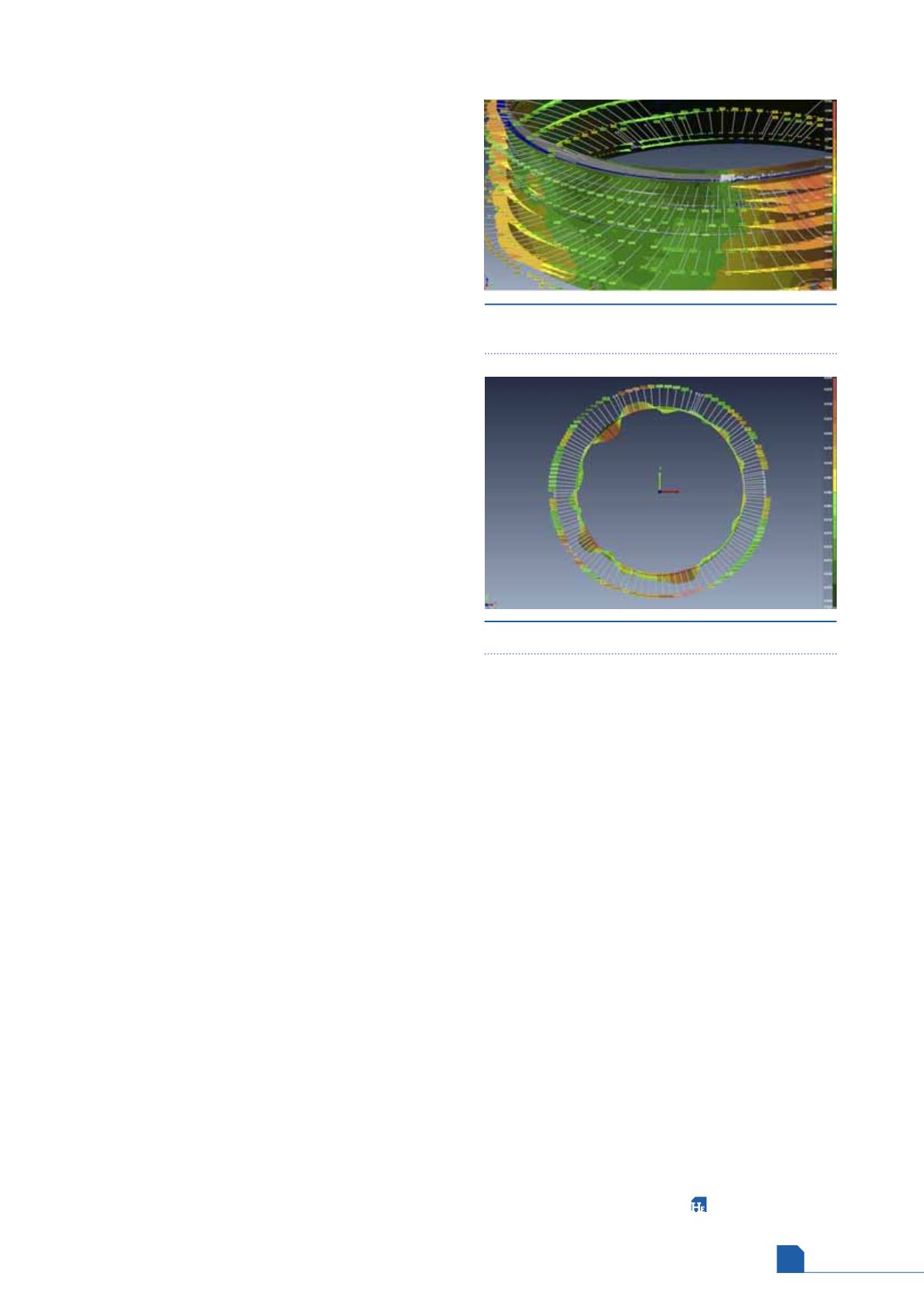

Figure 4.

Detailed areas of shell plate bulge and

indentation.

Figure 5.

Plan view of detailed shell plates.