March

2017

HYDROCARBON

ENGINEERING

138

nozzles, stairways and stiffening rings. The resulting

data collected may therefore be limited to only a few

hundred data points, with some of the inaccessible

areas of tank shell missed entirely. In worst case

scenarios, the inaccuracy or absence of data can result

in costly incidents where tank integrity is lost.

In comparison to these traditional methods, a laser

scanner can collect several million data points,

providing detailed information about the tank and the

surrounding area without the need to be in contact

with the tank. Laser scanning can be used to

accurately map entire facilities as well as provide

bund volume calculations and modelling of all local

pipework and their supporting structures. This

technique helps to minimise human error and leaves

the client with a much higher resolution, detailed

report that can be exported as electronic files that are

compatible with the clients’ design software, such as

2D computer aided design (CAD) files.

During the calibration of a storage tank, the

traditional method would involve taking reference

from a strapping table to calculate tank volume. A

global positioning system (GPS) workstation would

also be used for the purpose of finding the centre

point of the tank. Following this, the distance from

the centre point to the tank wall would be manually

calculated using a tape measure. Typically, in one

working day, approximately 160 different points would

be measured from the centre to the internal wall. In

comparison, a laser scanner collects millions of

reference data points within minutes, saving

considerable time for plant personnel and money for

the asset owner. By comparing either an existing

internal scan, or the original fabrication drawings, with

the external scans, the deadwood volume inside the

tank can be accounted for – providing in-service tank

strapping tables.

The scanning process

Following the scanning of the tanks, the files are

registered and imported into Advanced 3D Laser

Solutions' (ALS) analysis software. Data that is not

associated with the tank analysis, including stairs,

pipework and manways, are then removed from the

file. The analysis process is able to rationalise overlaps

in scan data while it simultaneously creates a

deviation map. Selected radial cuts and later

segmental cuts prepare the file for reporting radial

and vertical alignment. Further analysis performed on

the tank skirt is then processed in order to prepare a

tank settlement report. Finally, the captured data on

surrounding bunds is processed to calculate the

overall bund volumes.

Individual 3D laser scans can be combined to

produce a ‘point cloud’ file, giving the client a clear

view of shell verticality, shell plate radial deflection,

tank settlement and bottom edge differential

settlement. Consequently, as well as providing

cut-through views of the tank from both the X and Y

axis, 3D laser scanning eliminates the need for ‘dumpy

Figure 1.

Buried tank showing inside deviations of

shell plate internally.

Figure 2.

Overview of typical tank terminal scan.

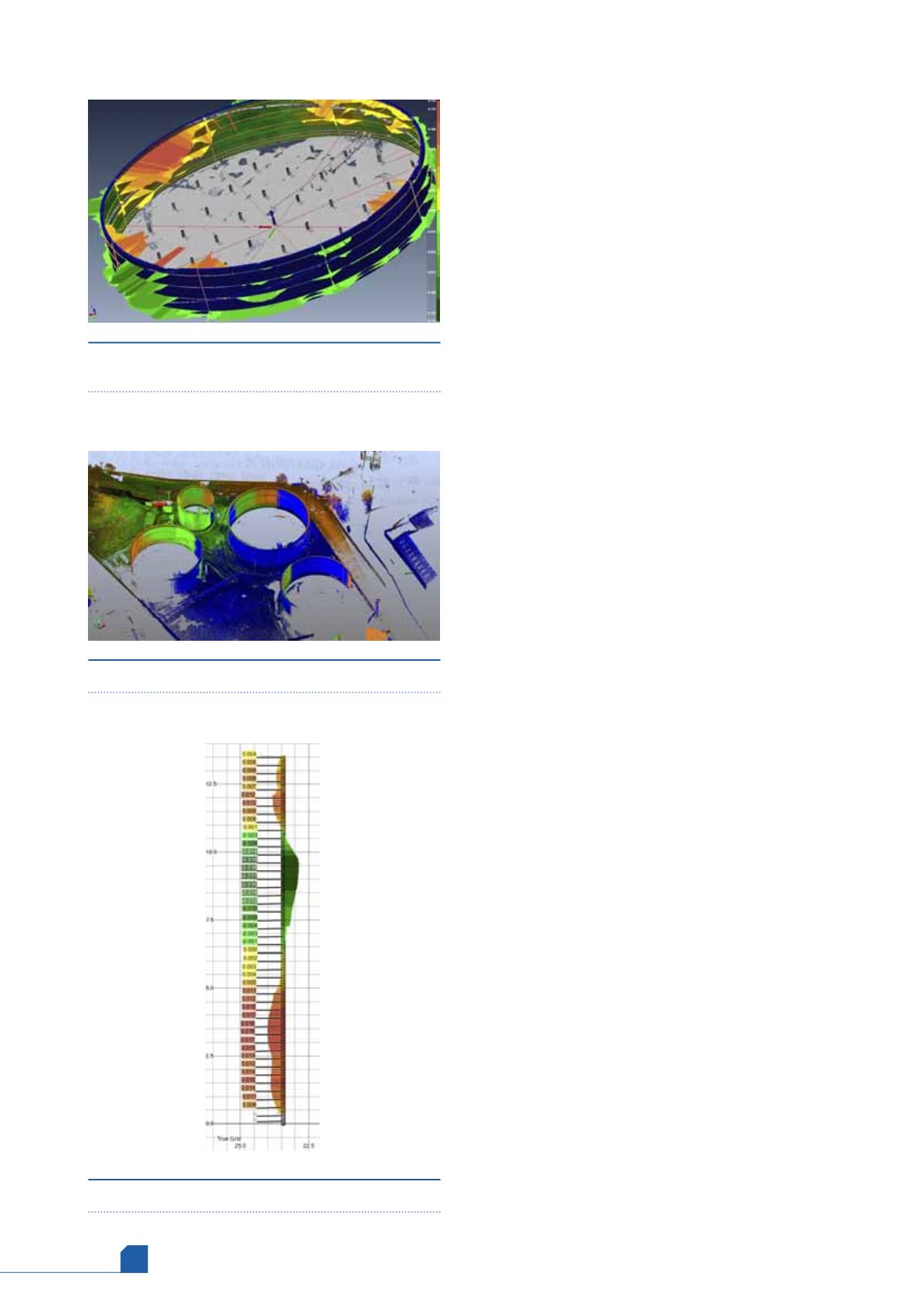

Figure 3.

Typical shell plate displacement on Y axis.